Seamless swimsuit shows performance of new Rascheltronic

By the end of the year, the company will have manufactured around 1,500 machines, almost all of them for international customers.

10th May 2016

Knitting Industry

|

Albstadt

Mayer & Cie., a leading international manufacturer of circular knitting machines, has reported the highest order entry in around 30 years.

By the end of the year, the company will have manufactured around 1,500 machines, almost all of them for international customers. By far the largest number will be shipped to China, followed by orders for India and Turkey, the company reports.

“Looking at our order entry since 1 January 2016, the current level is one that we last reached in the boom years at the end of the 1990s,” said Wolfgang Müller, Sales Director at Mayer & Cie.

At the turn of the millennium the knitting machine manufacturer was shipping around 2,000 machines a year. By the end of this year 1,500 machines are likely to have left the Mayer works – around 200 more than in 2015. In 2015 the company sold around 1,300 machines and Mayer Group sales totalled about EUR 100 million.

“There is a definite trend toward high quality machines. It was already apparent at the 2015 international textile machinery fair in Milan and it runs across the entire market – from Bangladesh to the United States. And the high quality segment, such as double jersey or jacquard machines, has always been our strong point,” commented Wolfgang Müller.

Another important factors in attracting more customers, the company believes is the current trend toward sustainability. There is more local production to local standards and requirements. In procurement too, the trend is toward locality, which eliminates long transport routes and gives purchasers flexibility, the manufacturer reports.

Another factors is the time to market, according to Sales Director Müller. The fashion industry is enormously fast-paced, with fresh goods being supplied to the leading fashion chains in some cases every other week. This means that although amounts to be produced are increasing, batch sizes are growing steadily smaller.

That requires fast response times for follow-up orders that are difficult to meet over long distances, the company reports. “Along with the increasing importance of quality more is being produced in the traditional textile markets, which is where Mayer & Cie. is very well established,” concluded Mr Müller.

The company considers Turkey an important tradition nearby textile market, from where it has already received orders for 76 machines this year. Most of them are for high-quality jacquard and double jersey machines. more distant regions with a long textile industry tradition – especially Central and South America – have also been placing more orders.

But the front runner for demand is China, which accounts for 154 of the orders received so far this year. “That is remarkable inasmuch as labour costs have risen significantly there. Ready-made goods in China are on the decline once more, but fabric manufacture is a different story,” said Wolfgang Müller.

Fabric manufacturing is booming in India too, which accounts for 94 of this year’s orders, making India the second most important sales market for Mayer & Cie.

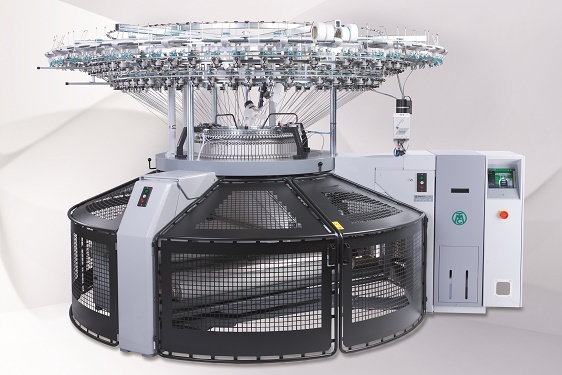

Among the top three machines of choice at Mayer & Cie., which sells its machines via around 70 representatives worldwide, the D4 2.2 II and the S4 3.2 II are sharing the first place. The former is a machine for double jersey, rib and interlock fabrics, while the S4 3.2 II is a flexible and productive single jersey machine. Over 110 of each have been ordered so far this year.

The runner-up with 76 orders received is the Relanit 3.2 II, a Relanit series machine. The Inovit QC, another rib and interlock machine, also ranks third among the Mayer & Cie. bestsellers.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more