Karl Mayer acquires YTC yarn tensioner technology

By creating a new range of patterns on the FL 20/16 raschel lace machine, product developers at Karl Mayer have succeeded in developing something new and innovative that the German company says is set to revolutionise the production of sari fabrics.

12th December 2012

Knitting Industry

|

Obertshausen

By creating a new range of patterns on the FL 20/16 raschel lace machine, product developers at Karl Mayer have succeeded in developing something new and innovative that the German company says is set to revolutionise the production of sari fabrics.

“The trendsetting fabric has a unique appearance and can be produced extremely efficiently. The new fabrics are as beautiful as conventional saris and can be produced in a single piece, so that they can be manufactured extremely economically,” Karl Mayer explains.

The pattern, together with the sections that are patterned with specific designs, such as the elaborately decorated shoulder piece at the end, which is known as the pallu, are worked directly into the fabric by the FL 20/16.

Karl Mayer says that for simpler patterns, the embroidery process can now be dispensed with - a procedure that has always been carried out on net saris having marquisette or tulle constructions. All that has to be done is to hem the edges or as on the sample shown below – use hemming tape as another option to create a fabric with a perfect drape.

Karl Mayer explains that the increased performance of the FL 20/16 is the result of its technical features - Four ground guide bars and 16 pattern guide bars, each with EL drive, and the KAMCOS computer platform equipped with the Motion Control/Multi Speed facility, which permits the speed of warp yarn delivery and fabric take-down to match the specific requirements of the pattern.

When producing a complete sari with a length of 5.50m, the computer facilities of the FL 20/16 can handle the data sets for working up to 17,100 knitted rows. At a working width of 132 inches, this results in two matching saris being produced next to each other.

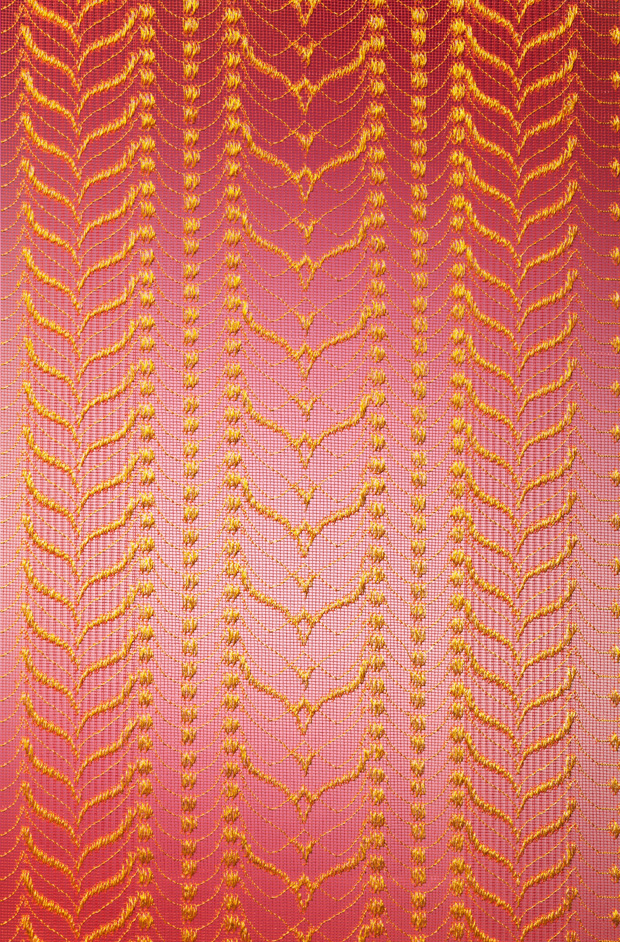

The pink and gold sari shown below has filigree, lattice-like ground with a dense, all-over pattern, whose relief-like characteristics make it look as if it has been embroidered. The multifaceted design is made up of diamonds, ovals, dots, dense stripes and, in the pallu section, teardrop paisley motifs.

This produces an effective ensemble, which is created by the 16 pattern bars on the marquisette-like ground construction. The three-dimensional design is produced by placing the pattern bars in positions 1 to 16, so that they are in front of the four ground guide bars. As well as graphic patterns and floral patterns, such as those shown below, similar decorative effects can also be produced.

Materials that have been designed to provide comfort support this attractive look, Karl Mayer says. For example, polyamide in the ground makes the fabric feel soft against the skin, whilst polyester is used to work the pattern. “These materials, in combination with soft-touch finishing, produce a fabric that is both beautiful and extremely comfortable to wear,” the company adds.

The patterning possibilities offered by the EL drive system for handling the ground guide bars can be used to increase the range of patterns that can be worked on the marquisette-like ground. The electronic control facilities and managing the pattern data of both the pattern and ground guide bars also enable the ground lapping to be changed within a repeat effortlessly. The fabric below shows an example of this. To produce the filigree design with its delicate, arching lines, a regular lattice-like ground was used, into which GB 17, 19 and 20 segmentally worked additional lengthwise stripes. As well as grounds with a marquisette look, tulle constructions can also be worked on the FL 20/16.

Processing yarns with different coloured sequences is another way of creating patterns on sari fabrics. The fabric below shows the wide range of optical effects that can be produced. A space-dyed, multicoloured yarn was processed to produce the pattern illustrated here, and its mixture of colours highlights the dynamics of the design elements attractively.

Additional coloured accents can be worked by combining the bright, iridescent yarns with single-colour yarns.

Karl mayer concludes by saying that no special know-how or additional equipment are needed to finish the warp-knitted sari fabrics. As is usual, the fabrics are washed, dyed, thermofixed, stentered and treated by carrying out soft-touch finishing.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more