Shima Seiki at Expotextil Peru 2023

The company will display its SWG061N2 Wholegarment knitting compact entry-level machine.

13th October 2017

Knitting Industry

|

Wakayama

Shima Seiki, a leading Japanese computerised flat knitting machine manufacturer, will exhibit at the upcoming Expotextil Peru 2017 show in Lima, promoting its Wholegarment knitting technology for the first time in Peru.

Without the need for post-production sewing, the on-demand knitting capability of Wholegarment knitting offers new business opportunities. The company will display its SWG061N2 Wholegarment knitting compact entry-level machine. “SWG-N2 offers great flexibility with the capability to produce a variety of items such as gloves, socks, leggings, hats and mufflers as well as childrenswear,” the company explains.

The latest in conventional knitting is represented by the SVR122 computerised knitting machine, which features the company’s patented Digital Stitch Control System (DSCS), Spring-Type Sinker System, Stitch Presser, Yarn Gripper and Cutter and Takedown Comb.

“Made-in-Japan quality, reliability, productivity, user-friendliness and cost-performance combine to satisfy the high standards expected by the fashion industry within Peru and beyond,” says the company.

Aside from the SWG-N2 series and SVR machines, knit samples highlighting the cutting-edge in computerised knitting technology will also be on display. Items produced on Shima Seiki’s flagship MACH2XS Wholegarment knitting machine, as well as samples knitted on SRY series and SVR-SP model featuring inlay technique that yield hybrid knit-weave fabrics, and new i-Plating technique, will also be featured.

“Unlike conventional plating techniques, i-Plating offers so-called inverse-plating capability in which alternate yarns are both shown on the fabric surface in any specific pattern or design, producing jacquard-like patterns in plain jersey stitch,” the company explains.

“i-Plating goes a step further, overcoming current limitations in inverse-plating by offering this capability within the same course and for individual needles for greater efficiency and expanded patterning capability.”

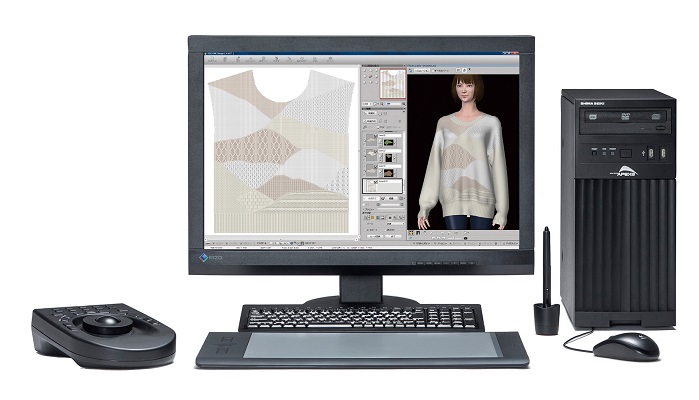

Also on display will be the SDS-ONE APEX3 3D design system. Key to Shima Seiki’s Total Fashion System concept, APEX3 integrates all stages of apparel production into one smooth and efficient workflow through comprehensive support from planning and design to production and sales promotion.

With ultra-realistic product simulations, APEX3 is also capable of Virtual Sampling that minimises the costly time- and resource-consuming sample-making process. Combined with the on-demand capability of Wholegarment knitting machines, such new retail trends as mass-customisation and e-Commerce can be supported.

Name: Expotextil Peru 2017

Date: Wednesday, 18 ~ Saturday, 21 October 2017

Hours: 12:00PM ~ 9:30PM

Location: Ciudad Ferial

Costa Verde - Circuito de Playas, San Miguel, Lima, Peru

Organiser: Plastic Concept S.A.C.

Tel: +51 (1) 714-9558

Booth: V6 (STT PERU IMPORT Booth)

STT PERU IMPORT SRL

Tel: +51(1) 473-9952

Email: [email protected]

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more