New selective terry options with Santoni SM8-TOP2ST

During the exhibition the company has displayed a range of innovative seamless items, the wool sport collection, and the sport-bras.

24th February 2015

Knitting Industry

|

Brescia

Italy’s Santoni, the leading knitting machinery manufacturer for seamless wear, exhibited an extensive range of seamless sportswear at the ISPO Munich trade fair for sports and outdoor textiles that took place in Munich at the beginning of the month.

The company has introduced prototypes of its innovative Santoni track jacket at the previous edition of ISPO. But an updated version of the reversible jacket was on show that was produced on the MECMOR CMP machine type with an integral combined knit and transfer feeds - a smaller version of the earlier machine model that retains most of the features of its predecessor.

In earlier models the knit and transfer systems had to be manually replaced according to the knit design. On the CMP machine however, the integral knit or transfer function can be selected to perform either function, as dictated by the knitting design, optimising the machine's production capability, Patrick Silva the company’s marketing manager explained at the show.

The totally reversible track jacket produced on this machine is said to provide great comfort due to its seamless characteristics. The border is not sewn as it is incorporated into the fabric panel, as well as the possibility to have incorporated the pockets. It is a double-face jacket and can have various patterns and logos.

The unique ultrafine (18 gauge) knitted fabric panel, which offers first class fabric uniformity and softness, is also said to allow a higher output capacity with greater resolution.

The previous double knitted panel was obtained with two different mono-colour yarns knitted at the same time. Now it is possible to produce the garment with different yarns, the company reports.

The sample on show was knitted with special yarns from Italian spinner Fulgar. One panel is knitted with wool yarns, whilst the other is in multi-colour nylon, all kept together by a bare elastane yarn. “Each side of the panel can be the front layer, allowing for either an active or a classical-sport look,” Patrick Silva adds.

“The versatility of the Mec-Mor machine has been also used for knitting sport caps and scarves. They are offered in sharp patterns and shapes, with dedicated areas for better comfort designed by using bare elastomers for a higher elasticity.”

During the exhibition the company has also displayed a range of innovative seamless items, including the wool sport collection, and the sport-bras produced on the TOP2V machine that Santoni launched in November last year.

The TOP 2V is an eco-friendly and totally conceptually reviewed new machine, provided with numerous exclusive patents. It is said to offer exceptional productivity, on average 30% higher than that of the current model and is incredibly energy efficient, the company reports.

Santoni’s SM8-TR1 machines for knitting seamless sportswear allow the production of garments with enhanced ventilation and wicking properties, and a range of garments was on show.

Patrick Silva comments: “Using the unique transfer needles on the machine to knit excellent quality mesh constructions in the garments, manufacturers do not need to use elastane to knit the mesh as it occurs on the TOP2 machine.”

In addition, the 8 feed machine also has special knitting needles with a unique Santoni-patented collar. This allows stitch transfer on this single knit machine when knitting mesh to give an extremely secure fabric with an even surface appearance. It is available in 24 gauge, which enables the production of all natural fibres.

The SM4-TL2 machine is a 4 feed single jersey electronical circular machine with reciprocal movement, two selection points per feed and per rotation sense. It knits single seamless garments for underwear, outerwear, sportswear, and sanitary wear.

On display were single colour leggings knitted with this technology and with one seam only. These leggings feature dedicated areas with a higher density elastomer so that the muscles can be better supported.

Also on display were socks and knitted footwear from Lonati and Sangiacomo machines, most notably the HT 1x160N; HT2 x120N x 4 ins and the STAR 120 N- 132N – 96N x 4 ins, which, with upgrades including a new Dinema electronic control and the Diagraph 3Plus software, knits with two feeds and has needles on the dial. Further production features on the Star include a rib elastic welt, double welt with the possibility of two elastics in two feeds, pattern socks with four colours plus grounds, jacquard rib socks, tuck stitch, imitation of mesh pattern and an imitation of links patterns.

Santoni's machines are well accepted by the most famous sport brands that have exploited their features to develop innovative garments that won the last two best Ispo product editions.

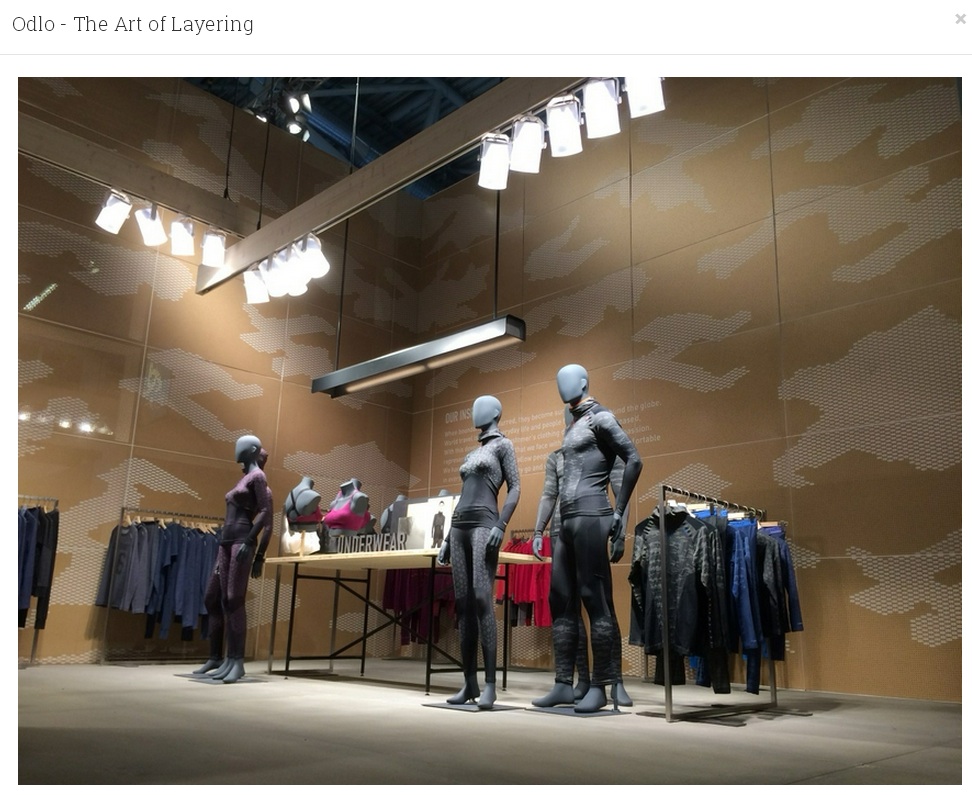

Last year Falke knitted its one-piece avant-garde seamless garment with Santoni’s warp knitting technology. This year Odlo won a prize with its seamless ‘entire recycled yarn’ sports garments knitted on the SM8/TOP2V machine.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more