Shima Seiki updates ITMA Asia Online Booth

With ‘Open Your Future’ as the company’s exhibition concept, the focus will be on supporting the technological evolution.

13th September 2016

Knitting Industry

|

Wakayama

Shima Seiki, a leading Japanese flat knitting innovator of Wakayama, will show its latest technology in Shanghai, China, this October, at the International ITMA Asia + CITME 2016 textile machinery exhibition.

At ITMA Asia, WHOLEGARMENT knitting will be represented by the flagship MACH2XS machine featuring Shima Seiki's original SlideNeedle on four needle beds and spring-loaded full-time sinker system. MACH2XS is shown in ultrafine 15L and mid-to-coarse 8L gauges. In addition, the compact SWG061N2 will demonstrate its flexibility for knitting a wide range of fashion items and accessories, as well as technical textile applications.

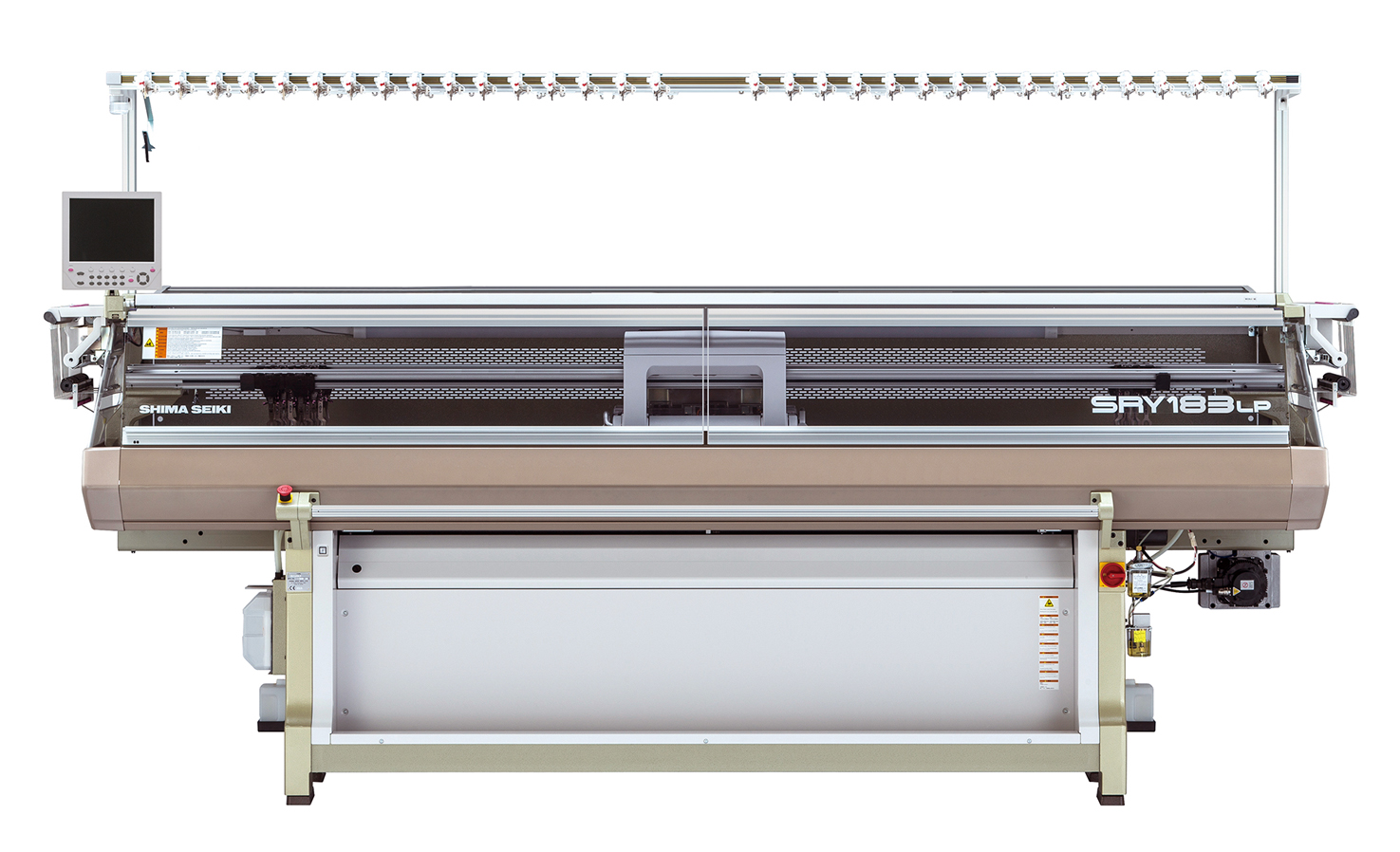

Other exhibits include the SRY183LP machine, shown with a 72-inch/180cm-wide needle bed for supporting garment-length production, as well as the brand new SVR123SP featuring a single loop presser bed located above the rear needle bed, making its debut at ITMA Asia in fine 14 gauge.

With Open Your Future as the company’s exhibition concept, the focus will be on connecting current trends with the future, with help from the right partners and the right technology. Shima Seiki offers its partnership and technological expertise for the benefit of knitting industries in China, Asia and beyond by anticipating upcoming needs in each of those markets, the company reports.

Because of their capability to produce an entire garment without the need for sewing or linking, WHOLEGARMENT knitting machines realize quick response production with on-demand capability thanks to reduced lead times, and offer reduced dependence on labour, as well as associated cost reductions, in addition to more sustainable production using the minimum amount of yarn required to knit a single garment, according to the manufacturer.

Introduced over 20 years ago for markets like the US, Europe and Japan as a countermeasure against the wave of inexpensive imports from China at the time, WHOLEGARMENT knitting became very popular within individual markets and factories that were determined to survive some trying times in the history of modern textiles.

WHOLEGARMENT knitting is now becoming of an increasingly great demand within the Chinese knitting industry that must now cater to a domestic market with growing demand for more fashionable items, while dealing with high wages and a diminished workforce.

The means for steady evolution is available to customers who are ready to take the next step in conventional flat knitting with the latest offerings in shaped knitting technology, the company reports. Especially of note are two machines with differing needle bed architecture; each with varying degrees of capability; and both with great potential for assisting growth in Asia with its diversified market needs.

The first is a machine that borrows heavily on Shima Seiki's experience with four-bed knitting, featuring a pair of loop presser beds mounted above a conventional V-shaped needle bed. The SRY machine is designed to offer full control over pressdown of individual loops for unprecedented capability in flechage and inlay patterns, opening doors to new possibilities in knit fashion with unique patterning potential. At ITMA Asia SRY183LP is shown with a 72-inch/180cm-wide needle bed for supporting garment-length production and an available maximum of 30 intarsia carriers for full intarsia patterning capability, in ultrafine 16 gauge.

The second machine is the brand new SVR123SP featuring a single loop presser bed located above the rear needle bed. Making its debut at ITMA Asia in fine 14 gauge, SVR123SP is capable of a wide range of knitting from fashion to technical textiles. Based on the industry-benchmark SVR-series, its triple knitting system is capable of highly productive knitting of complex structures such as inlay.

Further need for evolution is expected not only in knit production but also in managing the entire knit supply chain. Shima KnitPLM is said to offer comprehensive management from material sourcing, production planning and monitoring, factory and machine allocation, inventory control, and shipping, customized especially for the knitting sector.

Demonstrations will be held at ITMA Asia to show how KnitPLM can provide smooth and efficient workflow through each stage of the knit supply chain.

Exhibition: International Textile Machinery Exhibition – ITMA Asia + CITME 2016

Date: Friday, 21 October – Tuesday, 25 October 2016

Hours: 9:00AM~6:00PM

Location: National Exhibition and Convention Center (Shanghai); 333, Songze Avenue, Qingpu District, Shanghai, China; Tel: +86 21 62700066

Organizer: Beijing Textile Machinery International Exhibition Co.; Tel: +86 10 85229662

Booth No.: Hall 4, Stand C33

Shima Seiki MFG., LTD.

Tel: +81-734-74-8210

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more