Groz-Beckert to host virtual exhibition

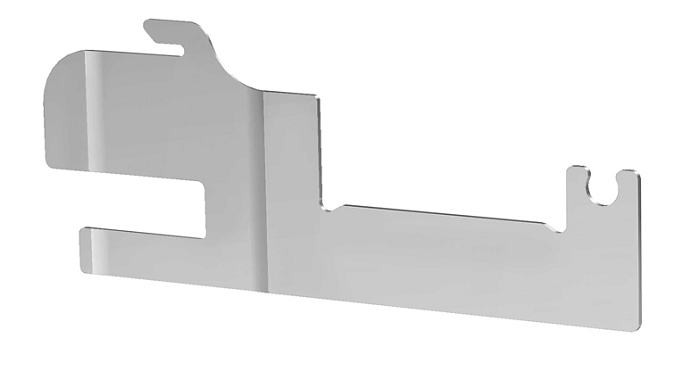

The smooth interaction of the individual sinker’s components is said to ensure long service life of the knitting elements and maximum productivity.

2nd July 2015

Knitting Industry

|

Albstadt

Groz-Beckert, the leading provider of industrial machine needles, is launching a new generation of sinkers, which are designed to provide a long service life and impeccable knitting results with a convincing price-performance ratio.

The smooth interaction of the individual components is said to ensure long service life of the knitting elements and maximum productivity and guarantee uniform loops and a trouble-free knitting process.

With such a selection of elements incorporated together in one work-flow, any kind of challenge can be handled easily, the company reports.

The company uses top quality steel, optimum edge rounding, straightness, precision and dimensional stability. But it is the synchronization of all technical properties that makes the sinkers unique, according to the manufacturer. The most popular sinker in Asia is the company’s SNK 35.31-15 G 6 type. This high performance sinker is mainly used in gauges E20–E28.

For extreme conditions in the knitting process, sinkers with local hardness at the yarn-impact areas are recommended. The decisive factor here is the right balance between base hardness and local wear protection.

These sinkers can be identified by the letters OL in their designation, like SNK-OL 46.20 G 16. Particularly suitable for challenging requirements, these sinkers are designed to provide a uniform loop structure for an even longer period.

The intelligent packing solution for sinkers completes the overall package, the company reports. At the upper edge of the butt the sinker has a cut-out. An elastic retainer is inserted into this cut-out, holding the sinker package securely together during transport and storing.

The sinkers are packaged in parallel position and do not have to be lined up in a time-consuming operation before use. For storing or cleaning the sinkers can be easily bundled again using this solution.

Acquiring needles that belong to the corresponding sinker as a package has a clear price advantage over buying items separately, Groz-Beckert reports.

Packages of matching needles and sinkers are available for single jersey, high-pile, hosiery and seamless bodysize machines.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more