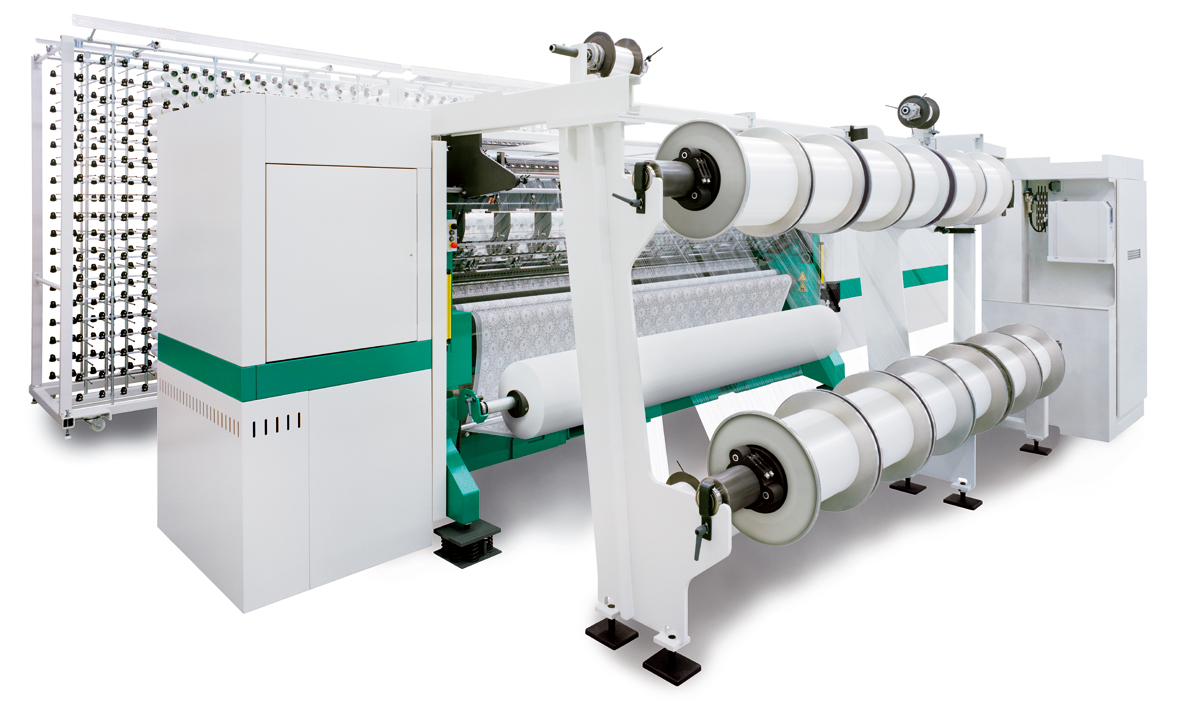

Seamless swimsuit shows performance of new Rascheltronic

Karl Mayer has introduced a new revamped version of ML 35 C multibar raschel lace machine called the ML 45, which it says will help its customers stay one step ahead in the dynamic raschel lace lingerie market. The company’s latest contribution to its strategy of rapidly introducing new technical innovations in order to cater for the market is that it has given its multibar raschel machines some ‘fine tuning’. With the introduction of the ML 35 C in 20

17th December 2008

Knitting Industry

|

Obertshausen

Karl Mayer has introduced a new revamped version of ML 35 C multibar raschel lace machine called the ML 45, which it says will help its customers stay one step ahead in the dynamic raschel lace lingerie market.

The company’s latest contribution to its strategy of rapidly introducing new technical innovations in order to cater for the market is that it has given its multibar raschel machines some ‘fine tuning’. With the introduction of the ML 35 C in 2005, Karl Mayer introduced its successful string bar concept as well as modern drive technology onto its multibar machine series. This heralded a new change of generation, which has considerably increased the performance of this new range compared to the multibar machines already on the market.

Karl Mayer has now developed the ML 45 and incorporated it’s tried and tested package of innovations, and has thus set even greater standards in terms of productivity, flexibility and quality. The company says that, when examining all the factors that have to be considered when making the decision to buy new machinery, the ML 45 offers very good potential which can be realised by utilising the machine’s high precision features and by the fact that all the knitting elements work in perfect harmony with each other.

Karl Mayer has now developed the ML 45 and incorporated it’s tried and tested package of innovations, and has thus set even greater standards in terms of productivity, flexibility and quality. The company says that, when examining all the factors that have to be considered when making the decision to buy new machinery, the ML 45 offers very good potential which can be realised by utilising the machine’s high precision features and by the fact that all the knitting elements work in perfect harmony with each other.

According to Karl Mayer, depending on the type of yarn being processed and the specific configuration of the pattern bars, the new machine can operate at previously unknown speeds of up to 800-850rpm and the impressive design of the warp beam frame represents a smart technical innovation.

The reason behind optimising the machine handling procedures was to enable the complex technology to be mastered and controlled easily. The machine design does not include an operator platform, enables yarn to be loaded from the floor, and does not require any of the usual lifting equipment. As well as being easy to load, the floor-level warp beam frames also allow easy access, without having to climb any steps or pass along narrow walkways.

Other advantages in terms of user friendliness include the electronic control system for fabric take-down and batching, low maintenance servomotors for driving the pattern bars, and a modern operator console with touch screen control.

Karl Mayer says that designs can be changed over very easily on the ML 45 and, above all, completely new and varied designs can be created. The machine can operate typically with shog distances of up to 170 needles and there are more guide bars than on the last generation of multibar raschel machines, which enables an extensive range of designs to be produced.

Karl Mayer says that designs can be changed over very easily on the ML 45 and, above all, completely new and varied designs can be created. The machine can operate typically with shog distances of up to 170 needles and there are more guide bars than on the last generation of multibar raschel machines, which enables an extensive range of designs to be produced.

As standard, the ML 45 has two ground guide bars in the front (GB 1 and GB 2) for stitch formation, followed by 42 string bars and a ground guide bar at the rear (GB 47) for processing elastane. Six of the string bars form a shog line and can also be fitted with multiple yarn guides. The option of being able to exchange ground guide bar GB 2 for six pattern bars (PB 3 to 8) means that the user can change over the machine to working with picot edging devices himself. If required, the number of ground guide bars can be increased to four. The additional GB 9 replaces the six pattern bars (PB 3 to 8) and enables ground structures to be worked with three guide bars. Another option is to use a further ground guide bar (GB 46) instead of pattern bars PB 40 to 45 to produce four-bar Powernet constructions or SoftTouch fabrics.

Karl Mayer also claims that in addition to its efficiency and rapid setting-up times, this flexibility makes the ML 45 the perfect machine for producing lace ribbons and full-width fabrics with attractive ground constructions.

The ML 45 enables lace manufacturers to react quickly and in a well-targeted way to the constantly changing needs of the dynamic lingerie market. Karl Mayer uses the latest production machinery and operates a system of continuous quality control in its production line, which guarantees that all the components are high-precision components and have a long service life.

Karl Mayer claims to also have achieved an exceptional price: performance ratio by keeping one eye on costs in every aspect of the machine design. Specific solutions for minimising the investment outlay include, among other things, integrating the cabling into the warp beam frame and the touch screen into the control cabinet. The profiles of the warp beam frame have also been changed and a particularly striking feature is that the design of the warp beam frame has been simplified so that there is no operator platform. The warp beam frame is loaded with sectional warp beams, and supplies the yarn in conjunction with the creels. The header housing has also been redesigned by taking a number of practical considerations into account.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more