Cifra launches innovative sustainable beachwear concept

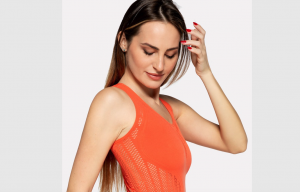

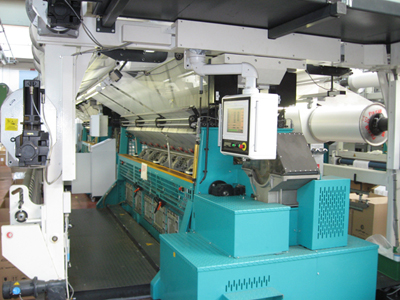

Italian warp knit seamless specialist Cifra SpA has launched two new seamless bodywear styles using its patented double needlebar raschel process. The garments are produced seamlessly on a Karl Mayer RDPJ 6/2 N double needlebar jacquard raschel machines with trims such as collars being sewn after knitting. Company owner and Managing Director, Mr Cesare Citterio told KnittingIndustry.com: “Cifra is world leader in the production of fishnet and fa

22nd October 2008

Knitting Industry

|

Verano Brianza (Milan)

Italian warp knit seamless specialist Cifra SpA has launched two new seamless bodywear styles using its patented double needlebar raschel process. The garments are produced seamlessly on a Karl Mayer RDPJ 6/2 N double needlebar jacquard raschel machines with trims such as collars being sewn after knitting.

Company owner and Managing Director, Mr Cesare Citterio told KnittingIndustry.com: “Cifra is world leader in the production of fishnet and fancy patterned pantyhose and seamless garments using jacquard double needlebar warp kinitting machines. Our articles are really revolutionary, in comparison with seamless items made on circular machines.”

Company owner and Managing Director, Mr Cesare Citterio told KnittingIndustry.com: “Cifra is world leader in the production of fishnet and fancy patterned pantyhose and seamless garments using jacquard double needlebar warp kinitting machines. Our articles are really revolutionary, in comparison with seamless items made on circular machines.”

Explaining the advantages over other technologies, Citterio said: “Because of the particular knitting technique these items are non-run or ladder proof. The garments that come out of the machines are really one piece and we make sleeves, necks, legs, gloves and everything really seamlessly”

Citterio also claims that from a creative point of view, the potential is huge and says that Cifra can design any kind of pattern or logo with no limitation on size, diameter, style or colour. Items only have to be dyed after knitting.

Cifra had a patent granted, which was published in 2003, which describes a method of manufacturing seamless garments on double needlebar raschel machines and the new styles use the same technique. The patent describes a method whereby a double needlebar jacquard raschel machine is used to create a seamless garment by creating three adjoining portions of tubular knitted fabric to give a body and two sleeves. The patent also describes a method for creating shirts or similar and pants using the same technique.

Cifra had a patent granted, which was published in 2003, which describes a method of manufacturing seamless garments on double needlebar raschel machines and the new styles use the same technique. The patent describes a method whereby a double needlebar jacquard raschel machine is used to create a seamless garment by creating three adjoining portions of tubular knitted fabric to give a body and two sleeves. The patent also describes a method for creating shirts or similar and pants using the same technique.

Cifra, which is located in the industrial area of Brianza near Milan, was founded in the 1960s when seamless fishnet tights first appeared and radically transformed women’s hosiery. Today Cifra is well known for its technologically advanced production and continues to invest in research and development for new products. The company utilizes only the best quality yarns and supplies the more prestigious world labels with fishnet and fancy patterned hosiery produced with the best quality nylon covered Lycra.

Cifra, which is located in the industrial area of Brianza near Milan, was founded in the 1960s when seamless fishnet tights first appeared and radically transformed women’s hosiery. Today Cifra is well known for its technologically advanced production and continues to invest in research and development for new products. The company utilizes only the best quality yarns and supplies the more prestigious world labels with fishnet and fancy patterned hosiery produced with the best quality nylon covered Lycra.

Cifra has more than one thousand different styles in its production catalogue and can also produce new designs and exclusive styles following customers' specific requests. Included in the service the client receives a direct guarantee on the pattern.

The capability to offer this kind of service is realized and guaranteed due to Cifra’s philosophy and flexible production system. Cesare Citterio says: “At Cifra the client can find a flexible, customer oriented business, ready to satisfy whatever request. This applies to both the large buyers and the small client.”

At Cifra creativity, productivity, flexibility and quality, are the key words that allow a fast growing business to operate successfully in today’s competitive business environment. Cifra realizes that globalization has in fact created a breed of producers that must concentrate on a type of production with higher added value in order to compete with countries where labour costs are lower. The production is guaranteed by the use of the best materials available on the market and Cifra recognizes the importance of utilizing only the most modern machineries and of anticipating the more advanced technology in the productive process. This capability is utilized in all the types of productive processes, both for tights made with Raschel looms, and for patterned pantyhose made with double needlebar jacquard machinery.

At Cifra creativity, productivity, flexibility and quality, are the key words that allow a fast growing business to operate successfully in today’s competitive business environment. Cifra realizes that globalization has in fact created a breed of producers that must concentrate on a type of production with higher added value in order to compete with countries where labour costs are lower. The production is guaranteed by the use of the best materials available on the market and Cifra recognizes the importance of utilizing only the most modern machineries and of anticipating the more advanced technology in the productive process. This capability is utilized in all the types of productive processes, both for tights made with Raschel looms, and for patterned pantyhose made with double needlebar jacquard machinery.

Cifra produces around 200,000 pairs of tights daily to its prestigious clientel which includes Golden Lady Group, Filodoro, Levante, Gizeta, Sanpellegrino and Franzoni, Hanes Hosiery, Falke, Wolford, Le Bourget, Sara Lee Group and Marks & Spencer. Cifra’s highly innovative seamless line, which includes t-shirts, lingerie, gloves, tights and sportswear, is completely created on warp knitting machines, the purchase of which was a strategic move which Cesare Cittero made when the rest of the market was starting to gravitate towards the production of seamless items made on circular machines.

Cifra produces around 200,000 pairs of tights daily to its prestigious clientel which includes Golden Lady Group, Filodoro, Levante, Gizeta, Sanpellegrino and Franzoni, Hanes Hosiery, Falke, Wolford, Le Bourget, Sara Lee Group and Marks & Spencer. Cifra’s highly innovative seamless line, which includes t-shirts, lingerie, gloves, tights and sportswear, is completely created on warp knitting machines, the purchase of which was a strategic move which Cesare Cittero made when the rest of the market was starting to gravitate towards the production of seamless items made on circular machines.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more