East Midlands students win Shima Seiki competition

Leading computerized flat knitting machine manufacturer Shima Seiki Mfg., Ltd. of Wakayama, Japan celebrated its 50th Anniversary on February 4th, 2012 and in November, the company held a gala celebration with over 1400 customers and 1300 employees over a 3-day period.

27th December 2012

Knitting Industry

|

Wakayama

Leading computerized flat knitting machine manufacturer Shima Seiki Mfg., Ltd. of Wakayama, Japan celebrated its 50th Anniversary on February 4th, 2012 and in November, the company held a gala celebration with over 1400 customers and 1300 employees over a 3-day period.

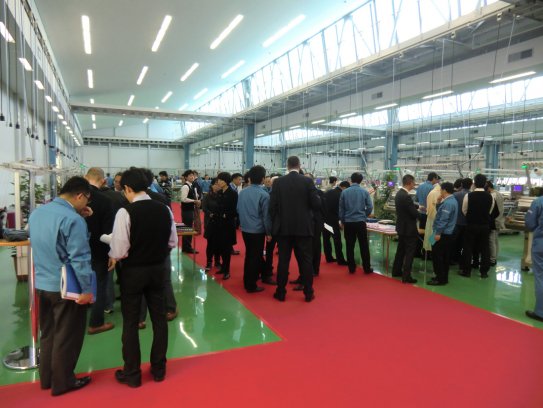

The event was headlined by a fashion show featuring some intriguing examples of Wholegarment and new integral knitwear. This was complemented by a vast exhibit of over 600 knitted items including samples from over 30 international apparel brands that use Wholegarment knitwear in their line-up, as well as students’ works from a dozen schools worldwide that currently use SDS-ONE APEX3 and related design systems. The latest line of Wholegarment machines was also exhibited, and several rooms were also set up for demonstrations on SDS-ONE APEX3 design systems.

Apart from the celebration mentioned above, Shima says it kept busy throughout 2012, which proved to be an eventful year worthy of celebration. The following is a list of those events in chronological order, most of which are centred on stimulating interest in the company’s Wholegarment knitting technology.

As significant and nostalgic a 50th Anniversary year may be, for Shima Seiki, 2012 was obviously not a time for resting on its laurels and basking in its past success, but a passage through which it busily laid its foundations for further progress over the next 50 years.

In March this year Shima opened a state-of-the-art factory on company grounds at its headquarters in Wakayama, Japan. The new factory, named ‘FA3’, is dedicated to the assembly of Wholegarment knitting machines. FA3 is named for being the third factory to bear the designation ‘Factory Amenity’, referring to the various features that help improve the environment for its workers, as well as for future generations.

Features included are:

The factory has a total floor space of over 2400 square meters and has a working capacity for 2000 Wholegarment knitting machines annually, in anticipation of increased demand for the still-new technology that is continuously improving and steadily gaining a loyal following among Shima Seiki customers.

To commemorate the opening of the FA3 factory, Shima Seiki held a private show featuring its latest line of Wholegarment knitting machines, using a portion of the factory floor as exhibit space.

Shima Seiki introduces five new machines in 2012

As a technology-driven company, Shima Seiki has continually introduced new technology year after year since its founding 50 years ago, and 2012 was certainly no exception. In addition to registering and applying for over 300 patents, the company introduced 5 new machines to market, as well as 5 other machines introduced as new models to an existing series, or new gauges for existing machine models.

New machines, models and gauges were mostly introduced at Shima Seiki’s Wholegarment private exhibition held in March at company headquarters, at ITMA ASIA + CITME 2012 held in June in Shanghai, China, and at the company's 50th Anniversary Celebration in the company’s hometown of Wakayama, Japan in November. They appear in the following list in the order in which they were announced.

SWG-FIRST154 S21 (New Machine) / S18 (New Gauge) / SWG-FIRST124 (New Model)

Introduced as a prototype at ITMA 2011 and premiering at ITMA ASIA + CITME 2012, SWG-FIRST154 S21 is the world's first flat knitting machine that can perform shaping (knit and transfer) in 21G.

It was also shown at the Wholegarment private exhibition in March along with an 18G version of the machine. Both feature, in addition to the SlideNeedle, loop pressers and transfer jacks, permitting a wide variety of patterns in a wide range of gauges never before possible. S18 can produce single jersey fabrics from 16G to 24G (19G for ribs), while S21 is capable of knitting from 18G all the way up to 26G (20G for ribs). A new short-bed edition, SWG-FIRST124, was introduced later in the year at SHIMA SEIKI's 50th Anniversary event.

MACH2X123 (New Machine)

The 4-bed SlideNeedle-equipped MACH2X series line-up was joined by the compact MACH2X123 at ITMA ASIA + CITME 2012. Complementing the 68-inch MACH2X173 and 60-inch MACH2X153, the 50-inch (125cm) MACH2X123 gathers high expectations as the most flexible of the trio.

Its compact size allows easier shipping and installation, while its knitting width is adequate for everything from small accessories and childrenswear to ladies wear and even some menswear. The same machine can knit Wholegarment knitwear as well as integral knits.

Three versions of MACH2X123 are available, each capable of efficiently knitting high-quality Wholegarment products in the following range: 8L (6-10G); 15L (10G- 15G); and 18L (14G-18G). The technology to knit ultrafine gauge Wholegarment knitwear in all-needle knitting is exclusive to Shima Seiki.

MACH2X103 (New Machine)

Also introduced at ITMA ASIA + CITME 2012 was an even more compact and lightweight Wholegarment knitting machine, the MACH2X103. MACH2X103 features a knitting width of 40 inches (100cm) and is capable of knitting most children’s sizes and some ladies wear, as well as Wholegarment accessory items. Such features as all-needle knitting, the SlideNeedle, R2CARRIAGE, i-DSCS+DTC and pull down device allow the same stable, high-quality knitting achieved by the larger models in the MACH2X line-up.

SWG021N (New Model)

Affectionately referred to as SWG-Mini, Shima’s compact line of Wholegarment machines aims to allow customers to participate in the Wholegarment market with minimal investment.

Returning after a hiatus of several years, the most compact among the SWG-Mini line-up was re-introduced at ITMA ASIA + CITME 2012 as the SWG021N, this time with the ‘N’ designation denoting the current generation line-up. With a compact knitting width of 10 inches (25cm), SWG021 is especially suited to high-quality knitting of Wholegarment gloves, socks, five-toe socks, leg warmers and other leg wear.

SIP-160F2S (New Model)

Shima Seiki’s SIP-160F2 inkjet printing machine line-up saw the addition of a ‘short’, compact model SIP-160F2S at ITMA ASIA + CITME 2012. At half the size of the larger SIP-160F2L, its possible range of installation is increased dramatically. With the same printing speed and features as its larger counterpart, SIP-160F2S enjoys an even greater cost-performance ratio, especially as a sampling machine for large-scale printing operations.

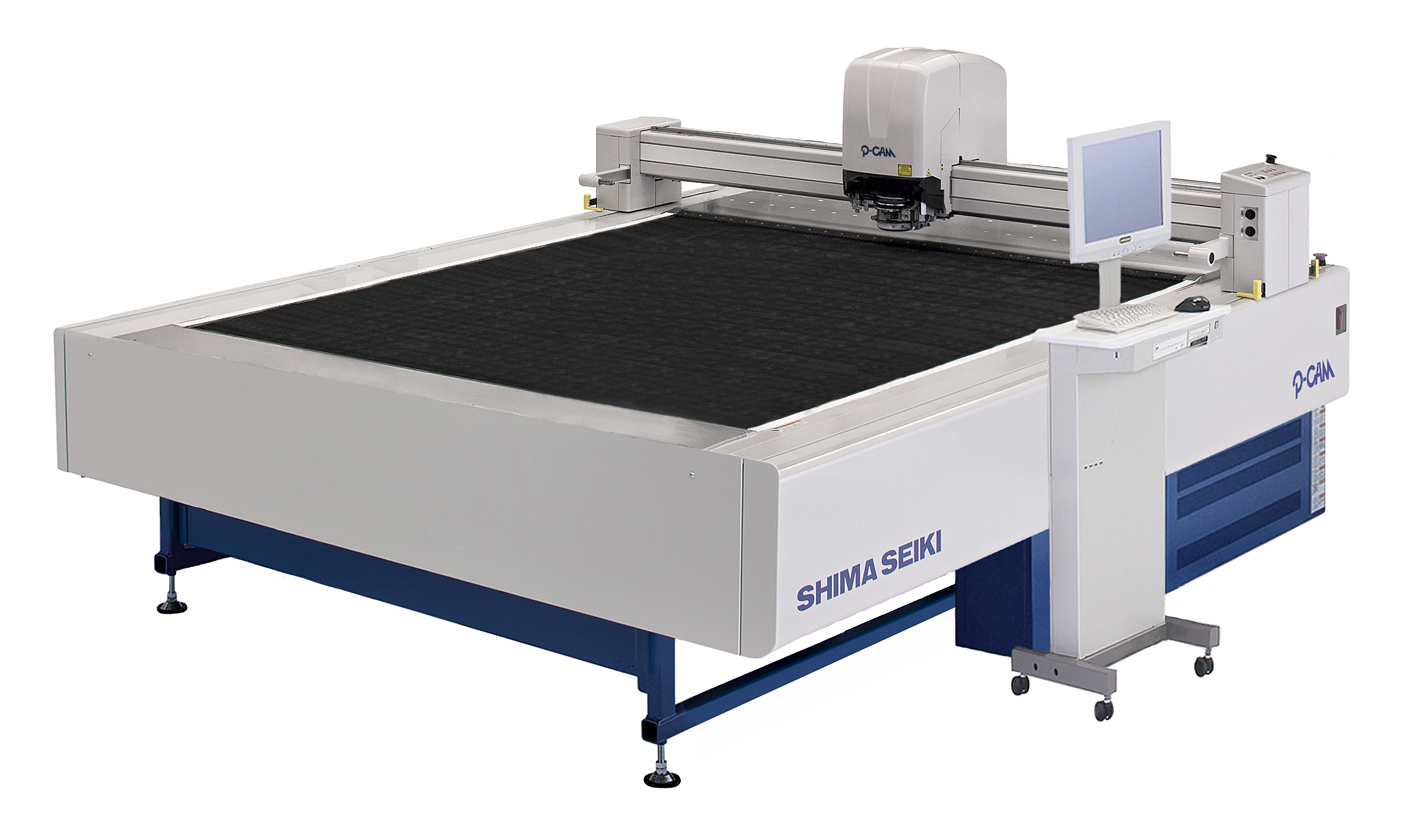

P-CAM120C (New Machine)

Shima’s diversified product line includes the P-CAM series computerized cutting machine which has gained a steady following worldwide for its speed and precision as well as full-featured CAD programming support from SDS-ONE APEX3. Its latest offering is P-CAM120C, introduced in October at the Japan International Aerospace Exhibition in Nagoya, Japan. A compact single-ply cutting machine for cutting industrial materials such as carbon fibre and glass fibre-reinforced plastics, P-CAM is also suited to cutting of industrial textiles for use in the automotive industry.

MACH2X173 5S (New Gauge)

A coarse gauge machine was added to the MACH2X line-up at Shima’s 50th Anniversary event. The MACH2X173 5S machine features a 68-inch (170cm) knitting width and 5G standard-hook needles. With the new machine capable of knitting Wholegarment knitwear ranging from 4G to 6G, the MACH2X line-up now covers a full range of gauges from 4G to 18G possible for all-needle knitting of Wholegarment items.

SRY123LP (New Machine)

SRY123LP is a new four-needle bed machine featuring two loop presser beds on top of a conventional V-bed. Appropriately released for the 50th Anniversary of a company that has thrived on innovation, the machine features the current iteration of a long evolution of patents surrounding the holding down of knitted loops for permitting the formation of various knit structures.

Beginning with Shima’s takedown system and evolving through the stitch presser and spring loaded full-time sinker system, the latest loop presser mounted across the entire knitting width over both front and back beds now allows hold down over every single loop, even for rib patterns.

This makes the SRY123LP especially effective in knitting flechage and inlay patterns in all-needle knitting. Inlay permits users the exploration of applications for non-elastic knits outside the realm of fashion. Non-elastic material as carbon fibre and other industrial materials can also be laid-in, paving the way for new non-garment applications such as industrial and technical textiles.

SDS-ONE APEX3 Realtime 3D View (New Feature)

Shima provided demonstrations on multiple SDS-ONE APEX3 3D apparel design systems as part of its 50th Anniversary event. It was the perfect opportunity to introduce its new Realtime 3D View function, which allows the designer to make changes to a design while viewing those same changes on a 3D image of a model wearing that garment, in real time. Using a large vertical monitor, it is possible to confirm these changes in life-size.

Review of Shima Seiki's 50th Year - Part 2

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more