BSTIM and Modtissimo to promote Iberian textile production

On display will be Shima Seiki’s latest line of computerised flat knitting machines, including those capable of WHOLEGARMENT knitting.

13th February 2017

Knitting Industry

|

Wakayama

Shima Seiki, a leading Japanese computerised flat knitting machine manufacturer, will exhibit at the upcoming Best Solutions in Textile Manufacturing Fair (BSTIM) in Igualada, Spain this month.

On display will be Shima Seiki’s latest line of computerised flat knitting machines, including those capable of WHOLEGARMENT knitting whereby an entire garment can be produced in one piece on the machine without linking or sewing.

The flagship WHOLEGARMENT knitting machine MACH2XS is capable of knitting items requiring tight, high-quality fabrics in all needles, thanks to its four needle beds using the company’s original SlideNeedle. Furthermore, MACH2XS has increased patterning range due to its spring-type moveable sinkers and optional inlay carriers, the company reports.

The smaller SWG091N2 WHOLEGARMENT knitting machine is designed to provide opportunities for highly flexible WHOLEGARMENT production over a wide range of items including industrial textiles, in a compact, economical package.

The novel SRY123LP computerised flat knitting machine features loop presser beds with inlay capability, offering new and exciting possibilities in knitweave hybrid fabrics, as well as technical textiles. The benchmark SVR series, as well as the SSR series workhorse shaping machines will round out the display with the latest in Shima Seiki computerised flat knitting technology. Among these is the new SVR123SP machine with loop presser bed and inlay capability shown at ITMA Asia + CITME 2016 held in Shanghai last October.

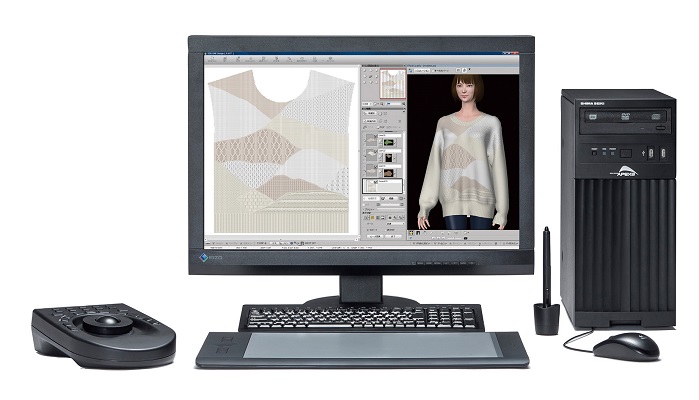

Also shown will be the SDS-ONE APEX3 3D design system. Key to Shima Seiki’s Total Fashion System concept, APEX3 has been developed to integrate all stages of apparel production into one smooth and efficient workflow from planning and design to production and sales promotion.

With ultra-realistic product simulations, APEX3 is also capable of Virtual Sampling that is said to minimise the costly time- and resource-consuming sample-making process.

Exhibition: Best Solutions in Textile Manufacturing Fair (BSTIM)

Date: Wednesday, 22 ~ Thursday, 23 February 2017

Hours: 10:00AM ~ 6:00PM

Location: Recinte L’Escorxador

c/Prat de la Riba 47, 08700 Igualada, Barcelona, Spain

Organizer: Fira D’Igualada

Tel: +34-93-804-0102

Booth: No. 24-29

Shima Seiki Spain, S.A.U.

Tel: +34-93-7293727

Email: [email protected]

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more