Taking a direct approach in Indonesia

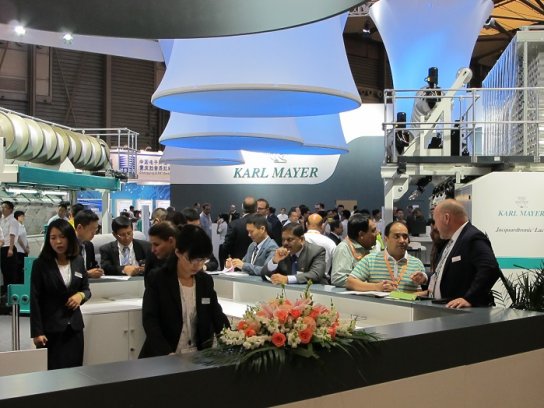

The displayed Karl Mayer machines demonstrated their efficiency during operation in front of a large audience.

17th June 2015

Knitting Industry

|

Obertshausen

Karl Mayer, the leading manufacturer of warp knitting machines, celebrates the successful exhibition launch at ShanghaiTex, an international trade fair for textile machinery that takes place from 15-18 June in Shanghai.

The displayed machines – a new terry tricot machine type TS EL, a performance-enhanced HKS 4-M and a Multibar Jacquardtronic Lace type MJ 59/1 S with special guide bar configuration – demonstrated their efficiency during operation in front of a large audience.

“Just on the first day our stand was well attended at all times,” commented Oliver Mathews, Sales Vice President of the Warp Knitting Business Unit. Already on the first day of ShanghaiTex the company managed to sell one of its newly developed machines.

Visitors come from the important textile regions of Southeast Asia and the Middle East – i.e. from China and mainly from India, Indonesia, Korea and Vietnam. According to Oliver Mathews, not only the number of visitors was satisfying, but also the general mood at the trade fair.

As expected, there is a rather subdued demand from China but on the whole there is a great interest in Karl Mayer’s innovations and customers’ willingness to invest in new machines, the manufacturer reports.

Karl Mayer exhibits a TM 4 TS EL terry warp knitting machine for processing cotton that can produce a wide variety of terry goods. By using a modern EL drive system instead of the old mechanical system, the speed of the TM 4 TS EL has been increased by about 30% compared to the old KS 4 FBZ when producing hand towels with borders.

The company is also showing an HKS 4-M four-bar tricot machine, whose speed has also been optimised. Depending on what it is being used for, this new high-speed model can reach up to 25% higher speeds than its predecessor.

A new MJ model, the MJ 59/1 S, is also on display. In the front position of the knitting elements, this new machine has a stitch-forming jacquard bar and not the normal pillar-stitch-forming ground guide bar. The fabric ground is therefore produced exclusively by the split jacquard bar. The characteristic appearance features a perfectly symmetrical, regular net pattern, worked on the basis of a powernet lapping, the company reports.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more