Karl Mayer acquires YTC yarn tensioner technology

Warp knitting machinery pioneer Karl Mayer will be exhibiting at next week’s ITMA Asia + CITME in Shanghai and says visitors to its stand in hall 5 will be treated to a first-class machine show.

8th June 2012

Knitting Industry

|

Shanghai

Warp knitting machinery pioneer Karl Mayer will be exhibiting at next week’s ITMA Asia + CITME in Shanghai and says visitors to its stand in hall 5 will be treated to a first-class machine show.

Main highlights will be a HKS 3-M machine of the 3rd generation which is said to be 15% faster than its predecessor but offers the same high flexibility typical of this machine range.

Another machine on display will be the HKS 2-3 E equipped with the 2nd generation of CFRP technology and operating at what Karl Mayer describes as ‘ extraordinary high speeds’.

For lace production Karl Mayer will be showing a new JL 65/1 B – a Jacquardtronic Lace machine, the design of which has been optimized and which will be operating with a working width of 168 inches, thus, the company says, ‘running at previously unreached speeds’. The user friendliness of this machine type is also said to have been further improved.

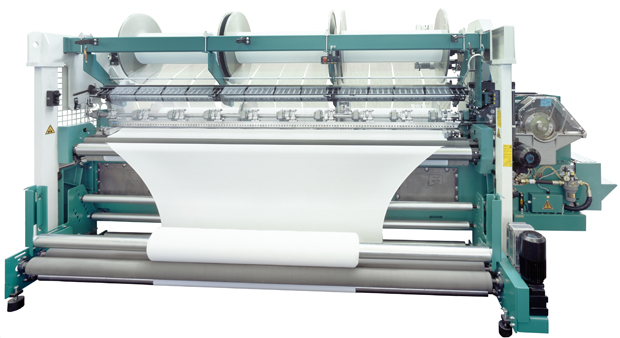

For the warp preparation sector, Karl Mayer will be showing its new fast, versatile Nov-O-Matic 2 with Isotens creel. This automatic sectional warping machine is said to be setting new standards in quality and productivity for producing long production warps as well as for processing batches with short running lengths.

These high-tech solutions will be located on an impressive stand made from textiles, a concept that has already created quite a stir at ITMA 2011 in Barcelona. In Shanghai Karl Mayer says its stand, with its soft, pleasant lighting, will once again invite visitors to rest for a while and also act as a meeting point for the sector.

While the exhibition is taking place, Karl Mayer will also be holding its own in-house show at Karl Mayer (China) Ltd., Changzhou City, in the district of Wujin. The TM 4-T EL for producing terry goods will be on show.

During ITMA ASIA + CITME 2012 KARL MAYER will be showing a HKS 2-3 E tricot machine equipped with the 2nd generation of CFRP technology, for high speed production.

The optimisation work of the lightweight machine concept mainly focused on segmenting the shaft for controlling the bars. This component used to be produced from a single piece and had to be heated continuously to guarantee reliable operation even at high speeds.

The new solution consists of high-precision segments which are virtually dimensionally stable, without the need to apply heat externally. When arranged in a row for use as the shaft, they aim to guarantee rapid start-up times and a high gauge accuracy, even at fluctuating ambient temperatures.

Karl Mayer says this enables even fine fabrics to be produced in a high quality at wide working widths and high speeds – such as will be demonstrated by a HKS 2-3 E in a gauge of E 36 at ITMA ASIA + CITME 2012. The machine exhibited this year will be manufacturing an elastic fabric for beachwear and sportswear, operating at speeds of up to 4000 rpm in a working width of 130 inches.

The HKS 3-M was the first model to be mass-produced with CFP bars at ITMA 2007 – a step, which increased its speed compared to the previous generation by 25%. This successful machine was upgraded again at the beginning of this year.

All the experience gained over the last few years was brought to bear to redesign and revamp the machine construction, which is now in its third generation. The knitting motion, machine frame and the beam let-off frame were completely redesigned, which increased the speed by more than 15% compared to the previous version.

The HKS 3-M offers the same high performance both in terms of applications and working widths. It is available initially with a working width of 210 inches and gauges of E 28 and E 32 but more widths and gauges will follow. The machine at the fair will work with a gauge of E 28.

As well as offering a higher maximum speed, the construction of the new HKS 3-M is much more compact. Access to the warp beam rollers on the right-hand side of the machine has been improved considerably, which complements the entire concept of the machine.

The new JL 65/1B – it is not only the working width and speed that have been optimised

The level of performance of the Jacquardtronic Lace machine has been improved constantly. The result of the latest upgrade made to the Jacquardtronic range was the optimisation of the JL 65/1B.

The development work carried out by Karl Mayer involved making specific modifications and changing the technical design, changes which considerably increased the productivity of the Jacquardtronic Lace with 65 guide bars.

These innovations on the new JL 65/1B and F models with a working width of 132 inches enable them to reach maximum speeds of 800 rpm, which means that they are 60% faster than their predecessors, Karl Mater says. The older machines operated at speeds of up to 500 rpm.

Also in this range is the JL 65/1B with a working width of 168 inches which, because of its overall design, can reach almost the same speed as its sister machine with a width of 132 inches. Karl Mayer says it is more efficient than the previous machine with its old design.

The performance has been increased by 25%, just by extending the width of the new machine from 132 inches to 168 inches which the company says will surely also convince the visitors to the show. During ITMA ASIA + CITME 2012 Karl Mayer will be presenting a JL 65/1 B machine with a working width of 168 inches and a gauge of E 24, which will produce a versatile lace fabric.

“The new machine concept also involved repositioning the pattern drive, with the string bars being controlled from one side. This change enabled the performance potential to be fully utilised for the relevant widths, and guarantees smooth machine running,” Karl Mayer says.

“As well as being extremely efficient, the new JL 65/1B operates at the same high level of precision offered by all Karl Mayer’s machines, and is easy to operate.”

“The latest optimised features have not reduced the patterning potential in any way. The patterns that could be produced on the existing JL 65/1 with a working width of 132 inches can be adapted for processing on the new machine, simply by modifying the pattern data.”

The innovative range Wefttronic RS was unveiled for the first time at ITMA ASIA + CITME 2010, and has been constantly expanded since then.

The modifications in the construction, which led to the development of the Wefttronic RS, focused mainly on increasing the speed and productivity. Consequently, the entire machine space and basic construction were adapted to the higher dynamics of the warp knitting process in order to increase the speed. In addition to increasing the production speed, the working width was also extended. This enabled the performance to be increased by up to 20%.

Another improvement in efficiency offered by the new weft-insertion machine has been achieved by improving the components used in weft insertion. For example, the guide system of the circulating chain has been re-designed, and the weft insertion system has been optimised. The weft carriage now contains 30 yarns instead of the previous 24.

The modified weft insertion system, with its ½-inch spacing, is also said to guarantees fault-free yarn laying without the yarns sticking together, which also increases the product quality. In order to produce a perfect textile, the entire yarn handling sequence on the machine was analysed and improved. These changes in the construction resulted in uniform zero inlay run-ins in the delivery unit and at the guide rollers, thanks to central supports and short yarn paths for the knitting yarns in the ground guide bars.

The recent developments have concentrated on complementing the range of working widths available. Whereas the first Wefttronic machine, which appeared in 2010, had a width of 268 inches, a version having a width of 138 inches was already available for ShanghaiTex 2011.

A Wefttronic RS in a width of 213 inches will exhibit at ITMA Asia 2012. This intermediate width is complemented by a machine having a width of 176 inches, which was launched at the same time.

The different working widths of the Wefttronic RS for the simultaneous production of several fabric webs next to each other can be fully utilised to achieve a high level of operating efficiency.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more