Symmetry makes the difference

Karl Mayer’s lace raschel machines are extremely productive yet flexible, and unleash their full potential thanks to their clever special features, which are being improved and optimised all the time, the leading warp knitting machine manufacturer reports. The latest developments include the introduction of a flexible patternguide finger system that enables the company’s clients to mount the patternguide fingers onto the string bars themselves by means of clips in line with the pattern. Until now, they have had to order adhesively-bonded string bars. Starting September 2014, every new machine will feature these flexible patternguide fingers. Machines that have already been delivered can also be operated using this new system. Special mounting packages with different features are available from the Spare Parts Division.

15th May 2014

Knitting Industry

|

Obertshausen

Karl Mayer’s lace raschel machines are extremely productive yet flexible, and unleash their full potential thanks to their clever special features, which are being improved and optimised all the time, the leading warp knitting machine manufacturer reports.

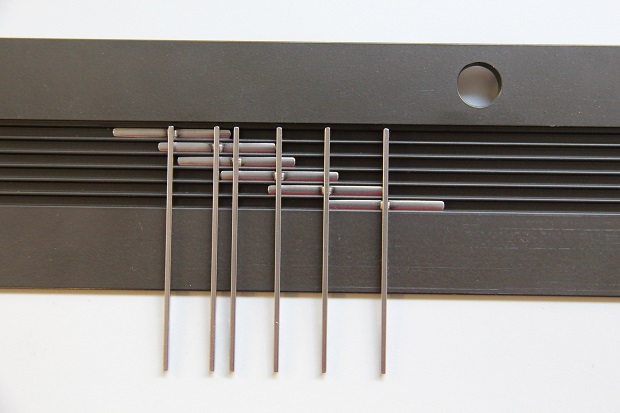

The latest developments include the introduction of a flexible patternguide finger system that enables the company’s clients to mount the patternguide fingers onto the string bars themselves by means of clips in line with the pattern. Until now, they have had to order adhesively-bonded string bars.

Starting September 2014, every new machine will feature these flexible patternguide fingers. Machines that have already been delivered can also be operated using this new system. Special mounting packages with different features are available from the Spare Parts Division.

This new system can be used without any additional guide elements and permits infinitely variable repeats to be worked. Any repeat width can be processed, without limiting the intervals in-between. The only restriction is the minimum distance between the patternguide fingers.

The patternguide fingers and strings can be re-used by clipping and unclipping them any number of times. The customer can carry out the work himself in his own plant, which saves time when changing the pattern. To reduce the changeover times, and consequently the length of downtimes, the customer can order additional string bar sets and mount the patternguide fingers onto the strings that are not being used, ready to work the next batch.

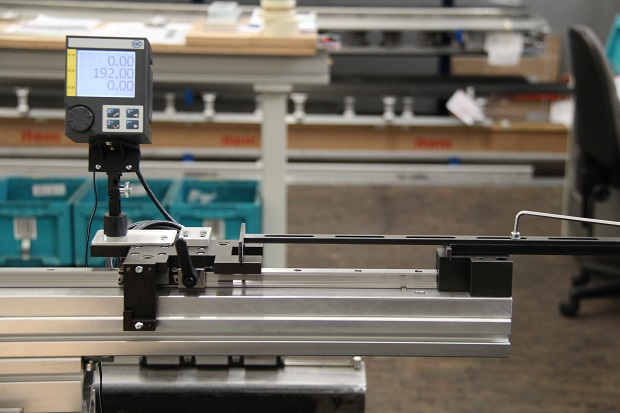

Karl Mayer has developed a special setting bank for producing the clip strings. The assembly equipment consists of setting nests and a movable measuring unit, which determines the repeat-dependent distances between the patternguide fingers according to data contained in the setting scheme and on the basis of the gauge.

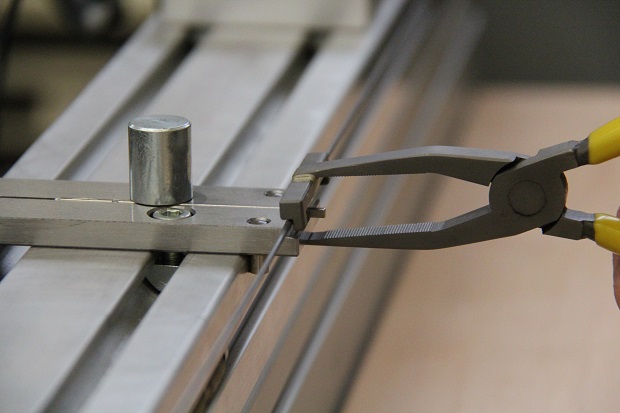

This arrangement enables the position of the patternguide fingers on the string to be located accurately, quickly and easily. The patternguide fingers are clipped on using mounting pliers and unclipped using disconnecting pliers.

Although this is a simple procedure, the clamping connection between the patternguide finger and the string is very secure and reliable.

From July 2014 onwards, Karl Mayer will be offering spare parts packages made up of different expansion phases for changing over entire plants. The service starts with supplying the basic equipment, such as the setting bank, strings and patternguide fingers, and ends with the setting-up of a suitable logistics system for fitting all the machines with minimal downtimes.

The advantages of the clip string system can be fully utilised by drawing-up an appropriate retrofitting plan. Karl Mayer is able to assist its clients with determining the right number of string sets for their plants.

“We first of all analyse the conditions existing in the client’s plant and ascertain, for example, how frequently the patterns are changed. On the basis of this, we work with them to develop a retrofitting strategy that takes into account the payback- and downtimes, the purchasing costs and the storage costs. By doing this, the potential of our machines can be exploited even more,” commented Axel Wintermeyer, Head of the Spare Parts Division at Karl Mayer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more