Shima Seiki updates ITMA Asia Online Booth

Leading flat knitting machine manufacturer showcases its latest technologies at Shanghai exhibition.

18th June 2021

Knitting Industry

|

Shanghai, China

Stephanie Lawson reports from Shanghai

The Shima Seiki booth was located pride of place at the centre of the Knitting Hall at ITMA Asia + CITME 2020, held in the National Exhibition and Convention Centre (NECC) in Shanghai last weekend. More coverage on the overall event can be read here.

Shima Seiki’s theme for this fair is to ‘Step Beyond’ expectations. Being a step ahead of the customer’s needs and the competition has always been the motto at Shima Seiki and now for industry at large it is key to survival when challenging external factors are influencing daily business so heavily. When IoT is prevalent across the wider garment industries, being a front-runner in DX and changing the landscape in ways of doing business is what moves the needle.

The booth itself was an example of the offline-online format. One part physical and one part digital, physical visitors could view the two latest machines, watch regular webinars on a big screen - also shared online - and access demonstrations and meetings directly with Japan in rooms at the booth. At the online booth there was detailed content for customers unable to visit the show including an introductory show video chronicling the latest developments from the company.

Limits on travel have brought arguably necessary advancements to an industry often lag-ging behind in technological development compared to other industries such as auto. In-built flexibility, automation and remote working using the latest technology have been propelled forward faster by the pandemic situation. Shima Seiki’s President Mr. Mitsuhiro Shima was unable to attend the show to greet customers, however he gave an online address recognition and acknowledgement that “Shima Seiki solutions are now becoming more vital and timely in knitting. Namely WHOLEGARMENT knitting continues to revolutionize the industry” and Shima Seiki, well accustomed to linking digital and materials worlds, is poised to do so with their latest machines.

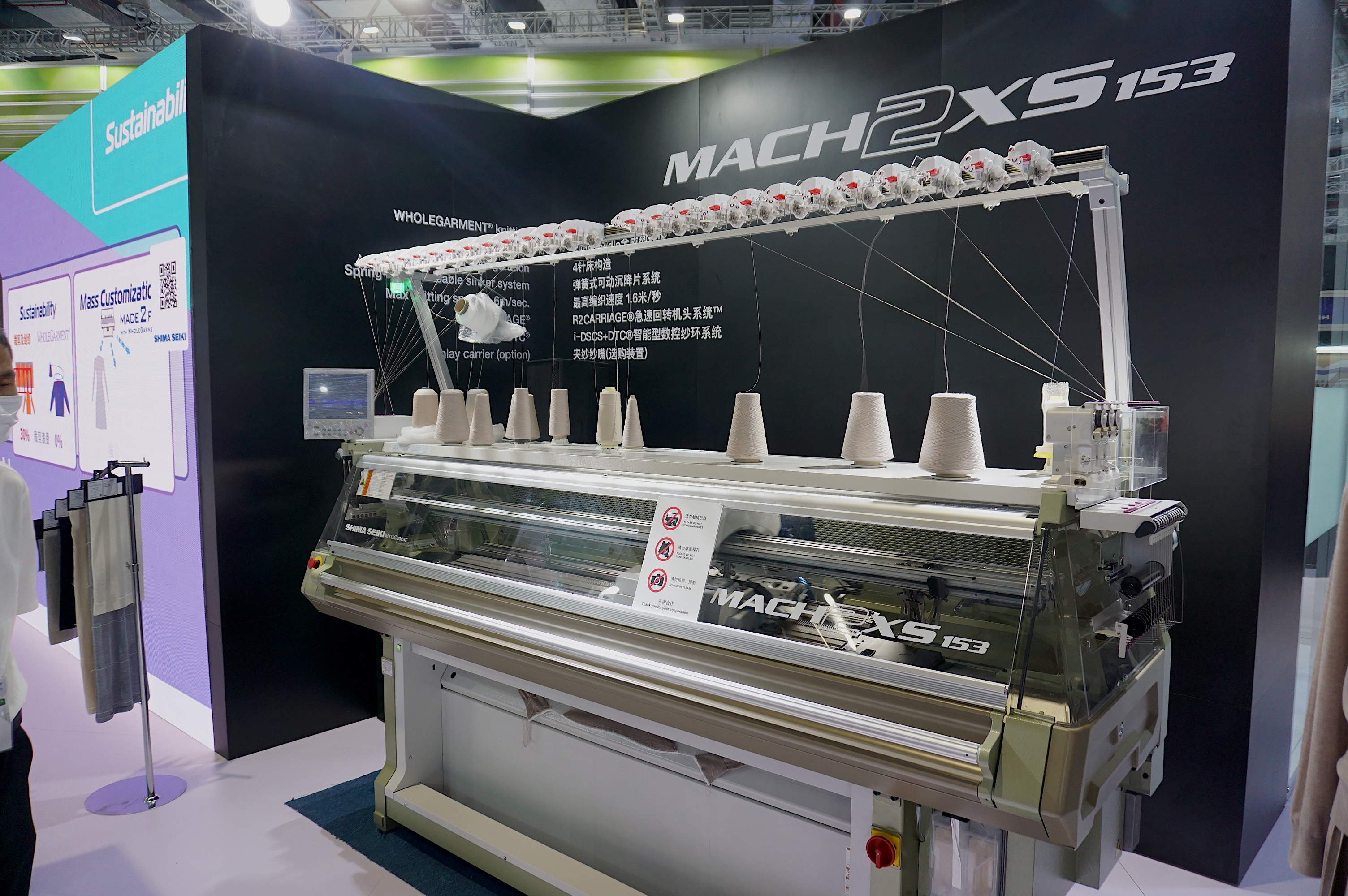

At the show were two machines, the MACH2XS, “the most advanced flat knitting machine in the world” and the MACH2VS, “a flexible V-bed machine capable of knitting WHOLEGARMENT knitwear using every other needle, or conventional shaped knitting using all needles.” According to Shima Seiki, the MACH2XS features proprietary four-needle bed and SlideNeedle technology combined with spring-type moveable sinkers and i-DSCS+DTC Digital Stitch Control System with Intelligence and Dynamic Tension Control, and capable of all-needle knitting of WHOLEGARMENT items.

The MACH2XS was presented in ultrafine 18L gauge, shown for the first time in China. In comparison to two needle beds in ‘V-bed’ formation, a four-bed machine uses every needle producing a garment much higher in quality, with denser more in form stitching producing a cleaner fabric and even texture. Spring-type sinker system hold loops down whilst knitting to produce more dimensional texture to the fabric and can allow for more interesting textures in cabling and larger 3D textures.

Shown for the first time in China, MACH2VS also features spring-type moveable sinkers and i-DSCS+DTC Digital Stitch Control System with Intelligence and Dynamic Tension Control. MACH2VS was shown in ultrafine 18G with auto yarn carriers as a prototype option.

New and prototype machines

Visitors were introduced to an as-yet un-seen but ‘game-changing’ machine named SWG-XR, throwing back to the SWG moniker from the first-generation WHOLEGARMENT knitting machine introduced back in 1995. The X represents 4 needle beds arranged in an X-shaped formation as the MACH2XS on display, while R stands for Reborn and Revolution, referring to a renewal in heritage WHOLEGARMENT knitting that raises the technology to unprecedented levels.

Featuring an additional knitting system and auto yarn carriers, SWG-XR allows even higher productivity and a vastly improved range of knitting for producing brand new WHOLEGARMENT items not possible before, such as the 3 designs featured below; punch lace uses specialised cams great for summer, 1-piece dress asymmetrical silhouette using variable stitch density and a unique 3-dimensional stitches using movable sinkers.

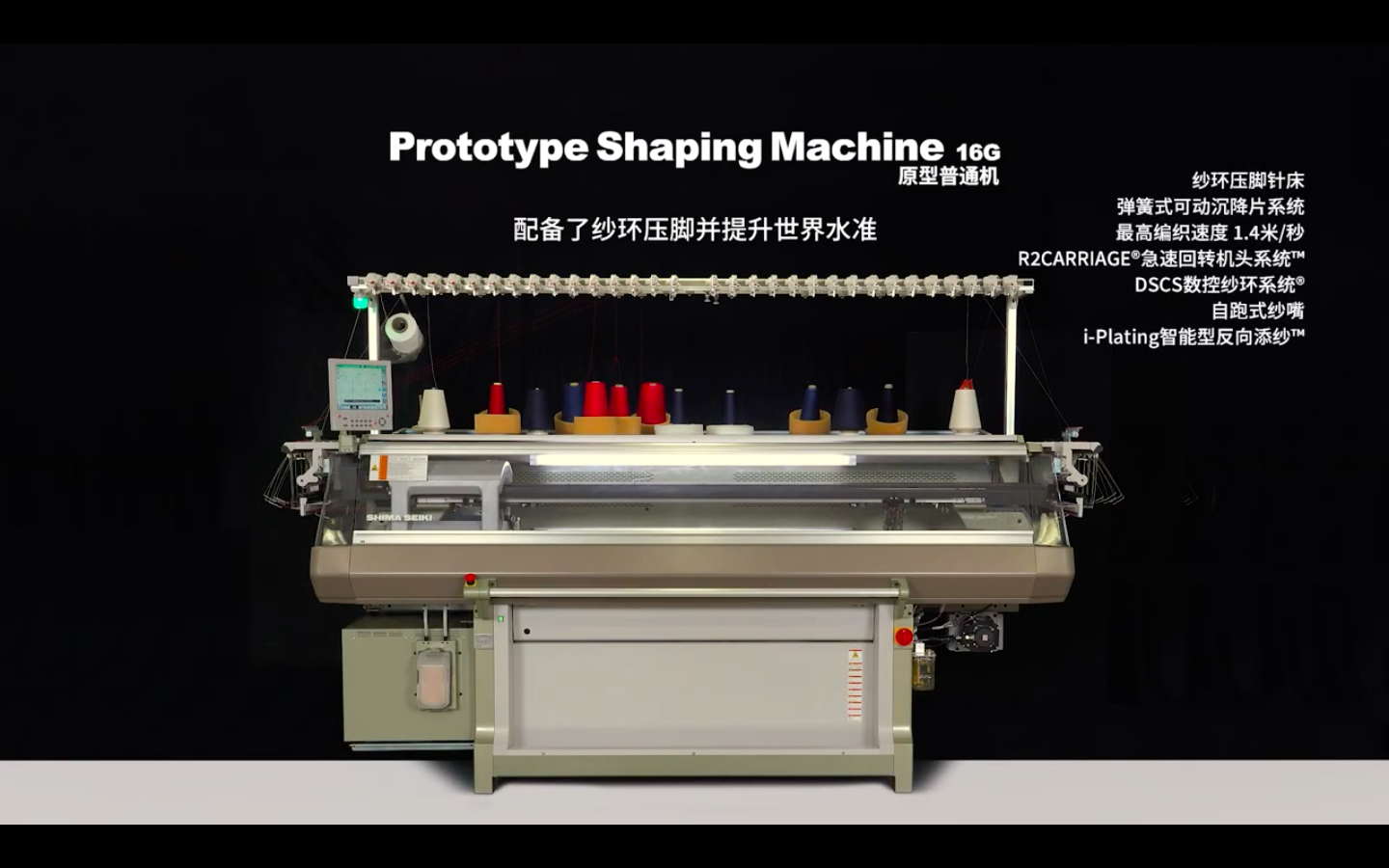

Also mentioned were two brand new prototypes, a shaping machine, and an intarsia machine. The 16G Prototype shaping machine possesses loop presser bed, spring-type movable sinker system and is equipped with loop pressers and improved knitting speed of 1.4 m/s. With a R2CARRIAGE Rapid Return Carriage System and DSCS Digital Stitch Control System, it also features an automatic yarn feeder and i-Plating Intelligent Inverse Plating System.

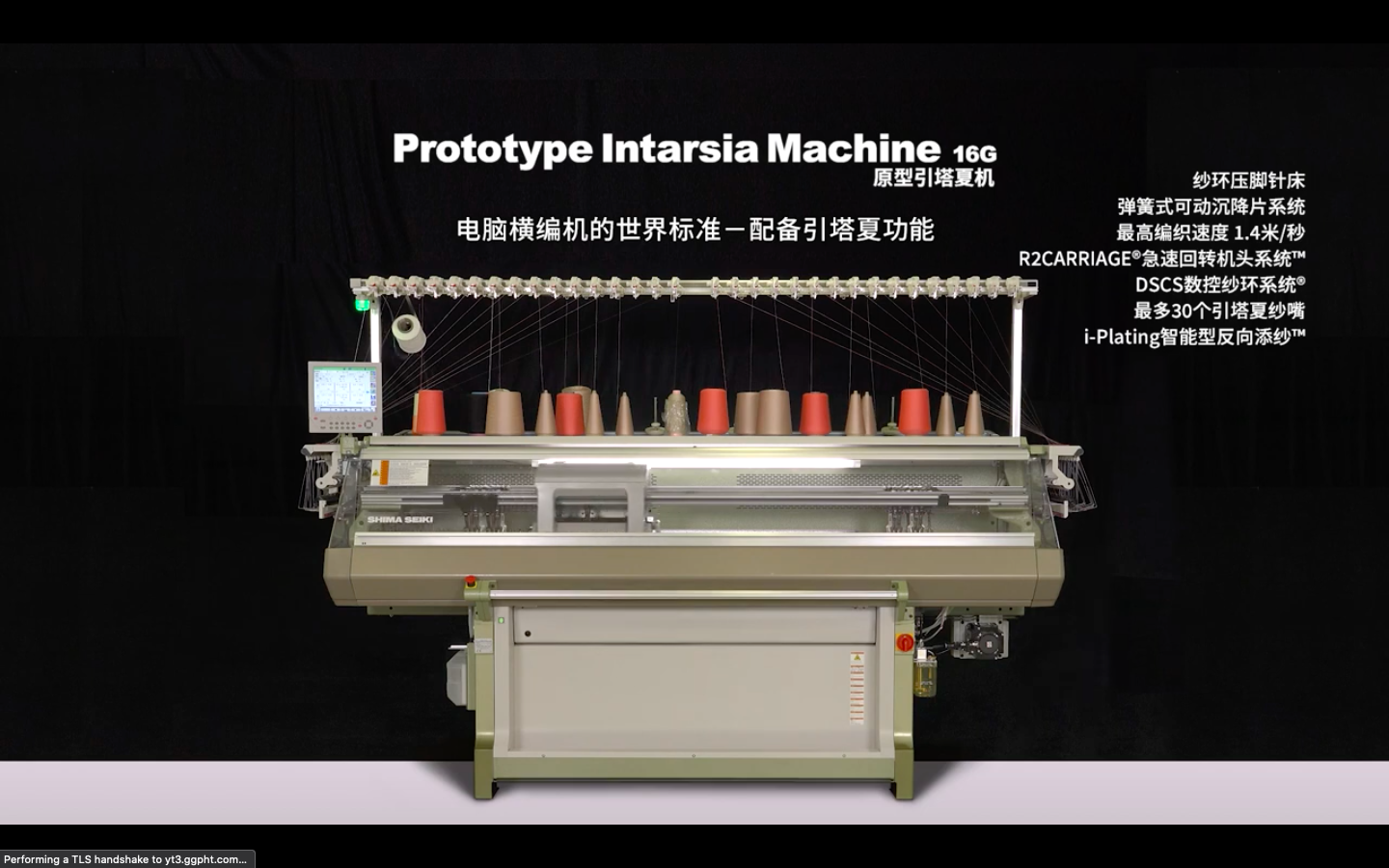

The Prototype Intarsia machine in 16G also has a Loop Presser Bed and R2CARRIAGE Rapid Return Carriage System, DSCS Digital Stitch Control System, i-Plating Intelligent Inverse Plating System and Spring Type Movable Sinker System as above-mentioned shaping machine. Above all, Shima says, it is world standard for computerised flat knitting machines equipped with intarsia function and has up to 30 Intarsia Yarn Feeders.

Visitors were able to envision what their newly purchased machine is capable of by checking the 250 samples on show at the booth, all of exceptional quality and workmanship and bearing the WHOLEGARMENT product tag, of which over 17 million examples have been circulated to date.

DX and APEX solutions

In discussion with Shima Seiki head of communications Masaki Karasuno, I asked if he thinks DX tools such as APEX and yarnbank have a chance to totally replace physical sourcing in addition to 3D design and virtual sampling. According to Masaki, the mindset of efficiency and savings is strongly shared with their key customers and confidence has been built up over time compared to early days when scepticism was high, and the realism of digital knitwear was less impressive.

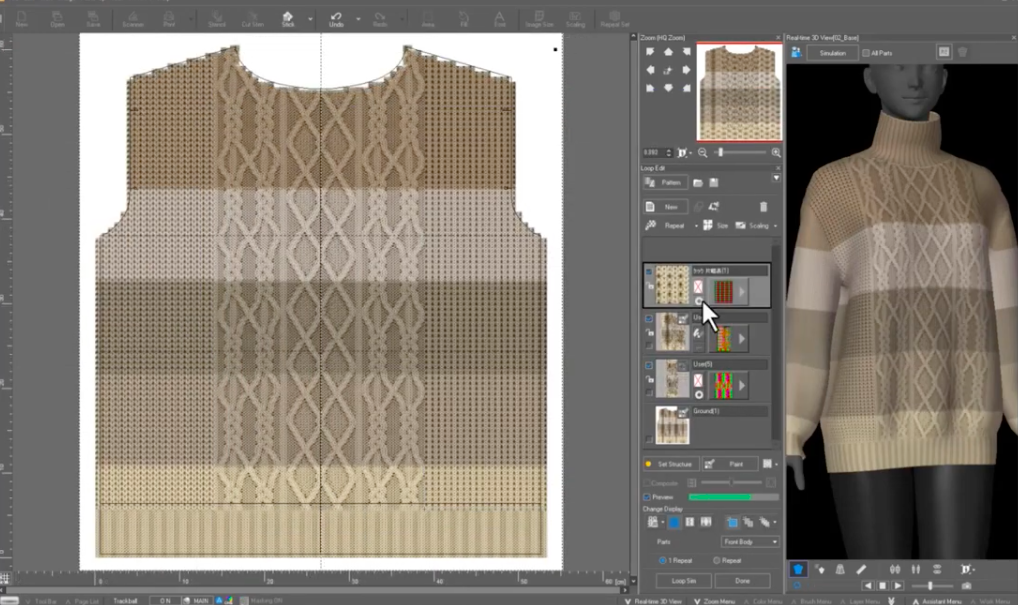

It is clear that companies need to take their share of evolving, adapting to new situations and software, if anything to get used to eliminating waste and make the fashion industry less wasteful than it currently is. The current sustainability push has fast-tracked this initial interest. Though APEX software and yarnbank are considered the highest quality knitting simulations in the world, Masaki says they don’t advocate 100% virtual sampling, “We will probably always need at least one sample of a new style before production gets underway,” he said.

APEXFiz software is the latest addition to the SDS ONE APEX series with one big difference. Now offered competitively as a subscription service, users are not limited by computer or office and can install on individual computers. It has low-cost one-off licence contract fee, followed by an affordable monthly software fee, making it more accessible to smaller brands and start-ups that may not have the purchasing power existing in large corporates.

APEXFiz Design Jr is the ‘basic’ package, which allows 3D fabric simulation. This can be upgraded to include 3D garment simulation and other services, at an extra cost. Recent updates include help menus that have been expanded and tutorials developed to further optimise usability. Within the program are 3 main functions - basic function, Knit and weaving. To learn more about how APEXFiz can be purchased and the different packages, click here.

Designed to integrate seamlessly with APEX software, yarnbank is constantly evolving and “it’s value comes in how many people are involved in it”. There is a constant influx of registered users and more yarns which serves both equally as a network is built up. Approximately 50 yarn manufacturers are currently registered on yarnbank and more are pending evaluation, in advance of Pitti Filati in Italy and a waiting list/evaluation stage. The majority of yarn manufacturers signed up are in Asia, including Japan, however the spread of those signed up is quite widespread globally. There are thousands of brand users already signed up and at the last count 900 yarn books created, which of course fluctuates by the season.

A recent focus has been to improve the ease of searching specific yarns, for example recently, “a special page featuring new and recommended products” was added. Another valuable addition to the software is the 3rd party certification which means designers and users can locate yarn by credentials or certifications e.g., eco yarns, Woolmark etc., which is a growing topic in these times. A demo video of yarnbank software can be also be viewed on the Shima Seiki website and anybody can sign up for free any time, though full value is gained through the combination of yarnbank with APEX software.

From a sustainability point of view, suppliers can save hugely valuable fabric resources, and time by moving towards a digital sourcing model, reducing need for so many sets of seasonal swatch cards. It is important that manufacturers and brands work together in supporting one another in moving forward, change can be difficult, but Shima Seiki’s SHIMANAVI service is designed to meet this challenge by providing e-learning services contributing to enhanced usability and remote support for users.

Shima Seiki is also renowned for benefitting customers with its vast archive of patent protection for WHOLEGARMENT technology - not limited to mechanical hardware, but also spanning software and programming, as well as stitch structures and knitting techniques.

Finally, amongst the company’s offerings during the demonstration was ‘Made2fit’ services offering consultation on mass customization solutions.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more