Discovering Machine Knitting

Groz-Beckert engineers needles and parts for success.

27th September 2022

Knitting Industry

|

Albstadt, Germany

Knowing Groz-Beckert as a trusted needle source, customers also have confidence in the company’s system parts. They rely on the individual components working together like clockwork, guaranteeing a smooth process and uniform loop structure. The knitting portfolio of Groz-Beckert includes more than 50,000 products. This article shows what a difference needles and parts can make.

A great customer benefit results from the development of holistic systems based on Groz-Beckert’s successful long-term partnerships with machine builders in Europe and Asia. The German company strives to ensure that its products fit perfectly into the machine concept. This is why machine builders select them as original equipment for their machines.

Circular knitting – needles specialized in high performance and low cost

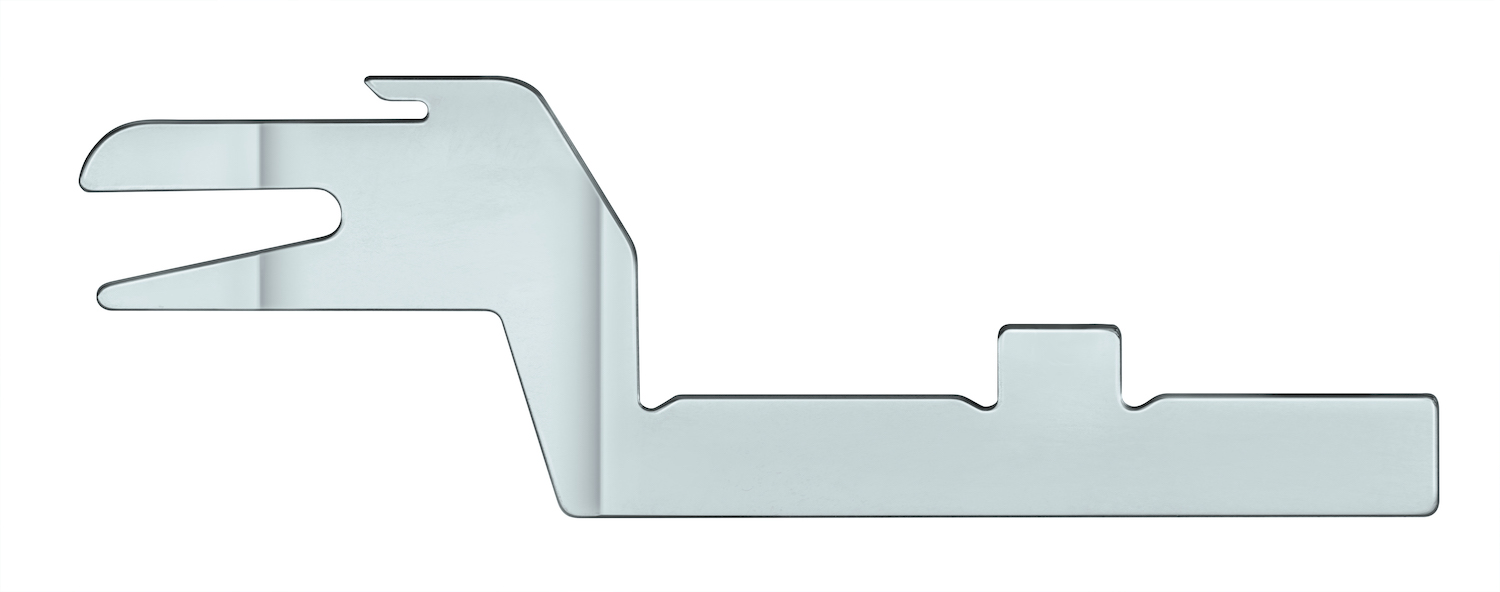

Lower energy consumption and reduced machine temperature are just two of the advantages provided by the ‘litespeed’ needle family, designed for the use in high-performance circular knitting machines. The optimized shank geometry of the litespeed needle generates less friction in the machine and consequently decreases power consumption. Oil consumption can be possibly decreased too: The partially reduced thickness of the needle shank allows a better distribution of the needle oil in the needle track.

When using staple fibre yarns on large diameter circular knitting machines, accumulations of fibre residues, fibre abrasion, dirt and other yarn components can result in deposits in the tracks of the needle and sinker carrier. These deposits often result in different positions of the needles and sinkers in the knitting machine, causing problems such as lines in the fabric or damage to the needle or sinker. To prevent this, the needles and sinkers have to be taken out of the machine for proper cleaning of the tracks. This causes labour costs and machine downtime. The combination of the special application needle SAN SF with the SNK SF sinker effectively reduces lint accumulation and significantly extends the time between cleaning cycles. Increased productivity and reduced production costs are the result.

Warp knitting – each part is a specialty

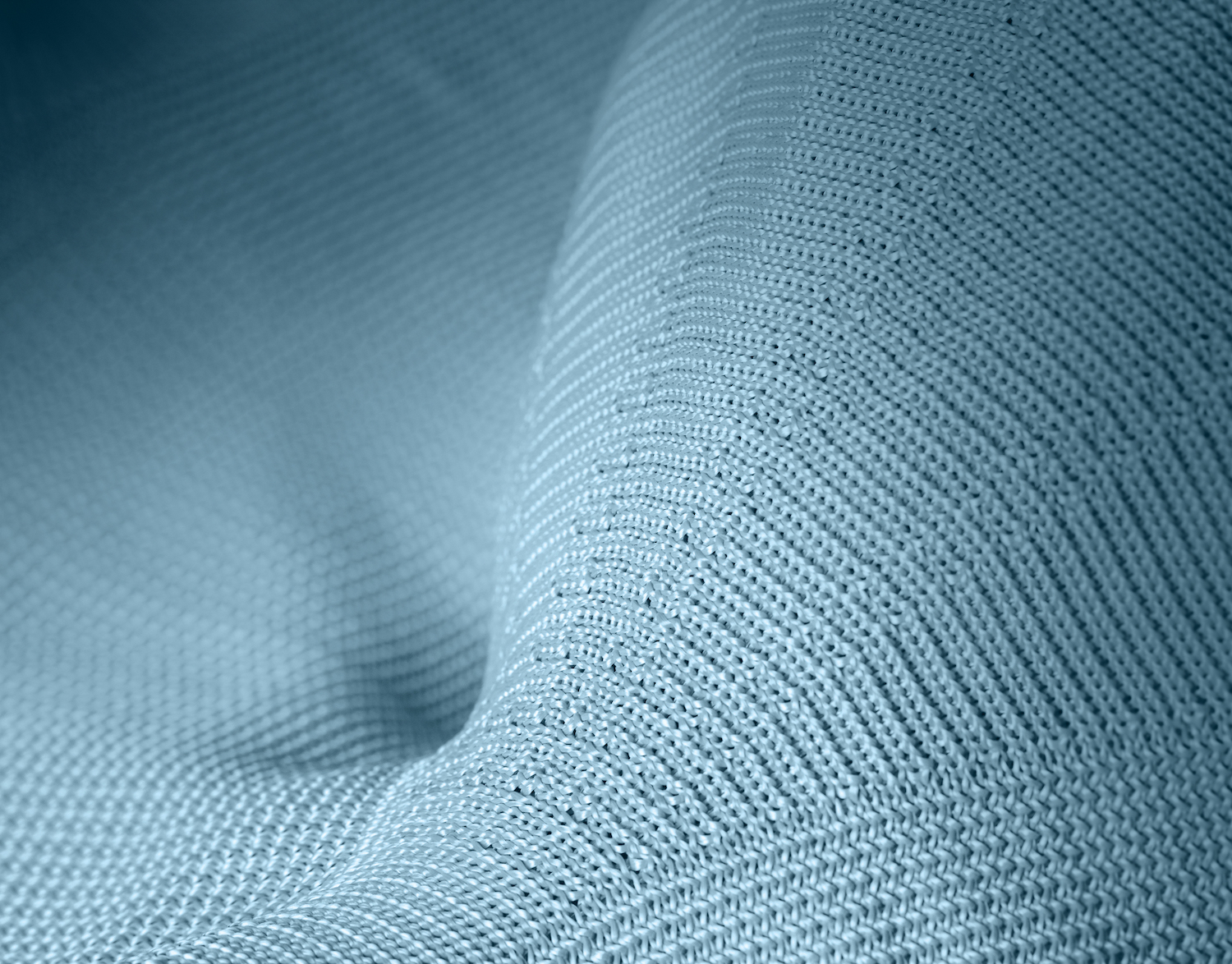

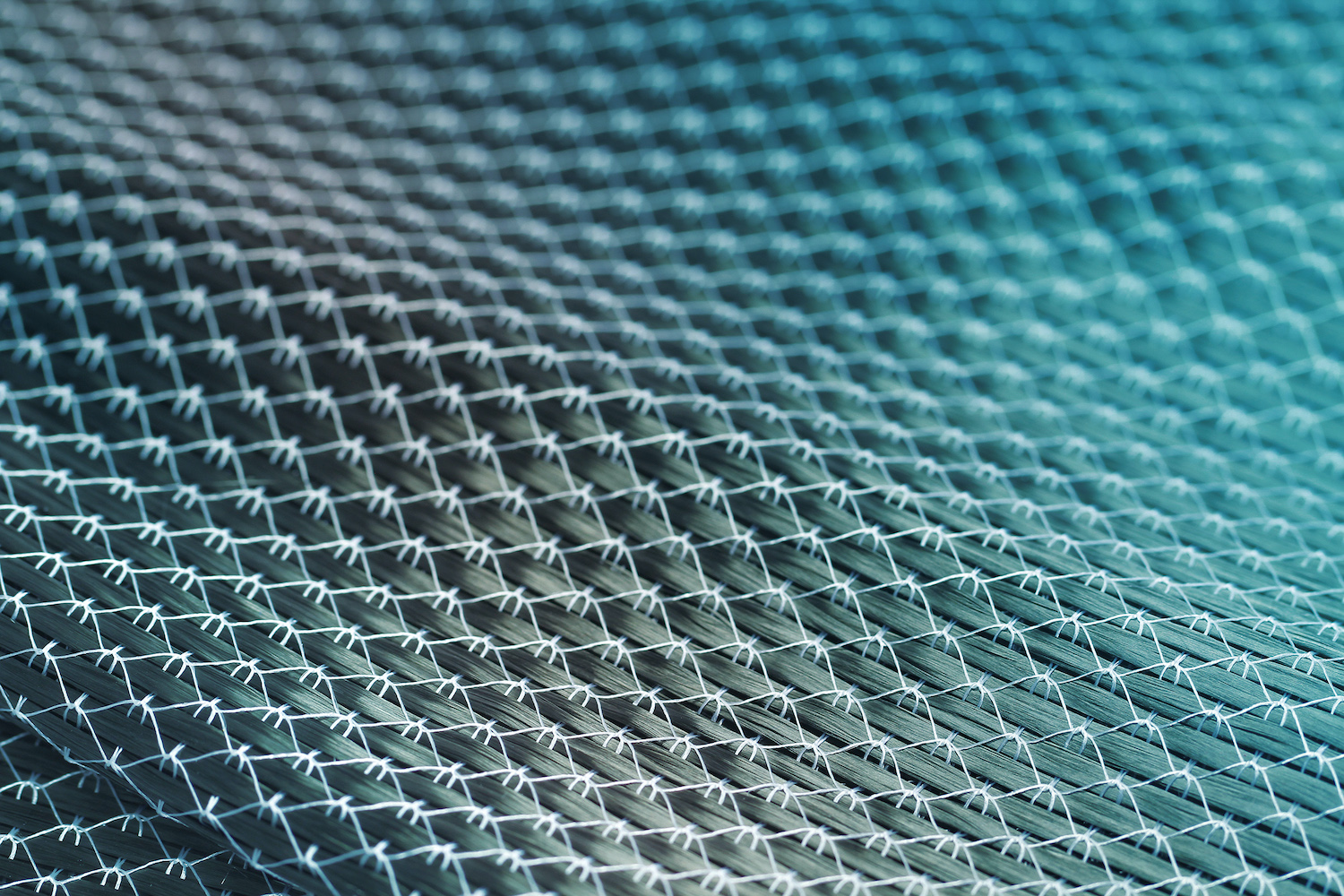

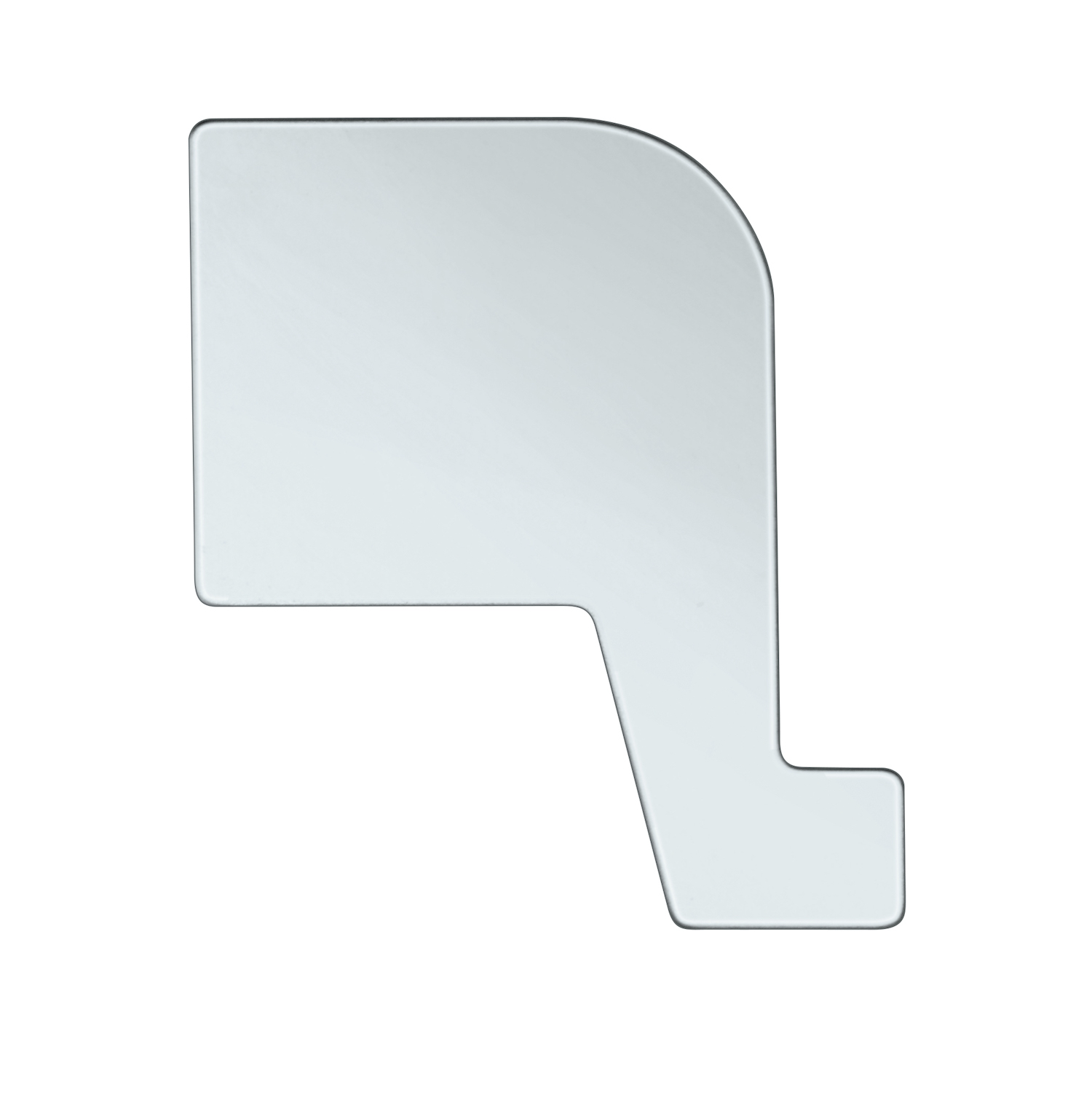

One well-known representative of this world’s biggest warp knitting machine product spectrum and its variant diversity is the compound needle. It is offered in a variety of hook and shank geometries as well as mounting options to ideally fit the different machine models. Compound needle gauges vary from E 1 to E 50. State-of-the-art development leads to customer benefits such as uniform loop structure and flawless fabric but also reduced machine downtime and highest productivity.

Flawless fabrics and highest productivity are also exactly what Groz-Beckert’s system parts for warp knitting machines stand for. Precision-manufactured and carefully coordinated individual components team up to build a system. Ideally matching functions and tolerances – even for highest speeds and finest gauges – guarantee a smooth interaction of all warp knitting tools. The result is a long-term stable knitting process and impeccable fabric quality. In addition, short set-up times and reduced machine downtimes mean highest productivity.

Flat knitting - specialties for the technical textiles segment

Special knitting techniques allow knitted shoe uppers to be produced from just one piece. There is no need to join several parts together, which in the case of conventional sports shoes means around 30 individual pieces. However, the production of knitted shoe uppers requires special properties from the knitting machine needles used. Knitted shoes are characterized by a high level of comfort: they are lightweight and fit the foot like a sock – also thanks to the SAN TT needle. In a nutshell: the SAN TT needle enables multi-thread knitting of tight loops with filament yarn without cutting individual filaments or threads in the closing movement of the latch.

In the development of the SAN TT needle, particular attention was paid to maximum process reliability during knitting. The special geometry results in less hook breakages, which means that the knitter benefits from reduced needle consumption and consequently less machine downtime. This leads to a significant increase in productivity, going hand in hand with a uniform loop structure and top quality of the knitted fabric. Low rejection rates and significantly reduced second quality provide a great added value.

Legwear knitting – one-stop for parts and components

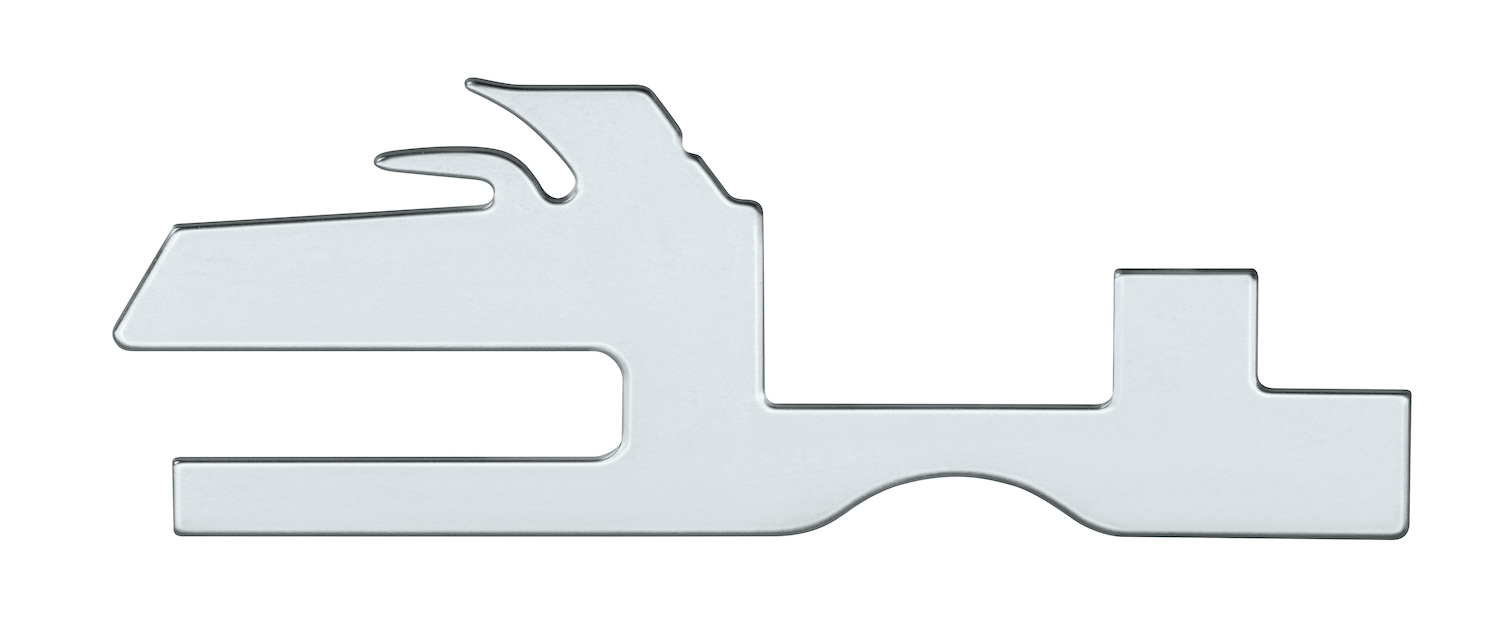

Legwear production distinguishes between three machine categories: single cylinder sock, double cylinder sock and hosiery machines. The Groz-Beckert portfolio covers them all, including sinkers, intermediate jacks, transfer jacks and system parts for toe closing.

Especially in very fine gauges, optimum edge rounding of the system parts is an elementary prerequisite for a uniform loop structure. That is why the edges of Groz-Beckert sinkers are excellently rounded. Another common issue in the production of legwear is wear to the yarn-impact area. Groz-Beckert offers sinkers with partially higher hardness in the relevant areas to ensure a longer service life and uniform loops.

The high technological level of sock machines is demonstrated, among other things, in the ability to automatically close the toes and thus produce a finished fabric in one operation. Toe closing requires maximum precision from the machine, needles and system parts to ensure perfect loop pick-up and transfer. Characterized by maximum precision and dimensional stability, Groz-Beckert system parts are therefore obviously a good choice.

Get the most out of it

Successful knitters have a common attitude - they focus on maximum output whatever they do. The suitable needles ensure trouble-free production and continuous saving. The right skills and best knowledge ensure great results. Groz-Beckert Academy is therefore a further key to success.

As world leader in producing knitting needles and system parts, the company offers a wide range of training courses and services from application advice to tests, laboratory services and the production of small and special series. Groz-Beckert also supports its customers and partners with product, application and basic knowledge along the textile value chain. Academy Mobile online seminars focus on a number of topics related to the textile industry in general and Groz-Beckert products in particular.

Last but not least, customers can take advantage of the Customer Portal offering services and benefits exclusively available online. Detailed product information including pictures, product features, technical data and equipment options are available at a glance.

Furthermore, prices, availability and delivery information in real time are displayed and orders can be intuitively completed. And besides unmatched quality, reliability as well as quick delivery is what Groz-Beckert is perhaps best known for.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more