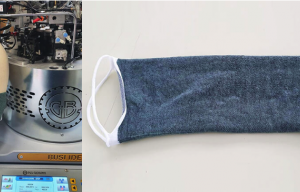

Busi socks knitting machines switch to making masks

Family-run sock machine maker drives sustainability and smart design.

10th July 2025

Knitting Industry

|

Botticino (BS), Italy

Italian socks knitting machine builder Busi is looking ahead and is determined to invest in process automation to boost efficiency and precision. In a recent interview with Greencompany magazine, CEO Catina Busi pointed out, “the humble sock is becoming a protagonist of daily comfort and wellness, evolving from a simple accessory to a vehicle for smart functionality.”

One example is the company’s collaboration with Soccerment, whose XSEED shin pad integrates AI technology to collect performance data for athletes. Busi’s Twin Layer machine creates a customised pocket in the sock that perfectly accommodates the XSEED, ensuring comfort and stability while enabling smart data tracking - an example of how Busi is combining advanced knitting with wearable tech.

Innovation has always been both the starting point and the outlook for Busi Giovanni, the Italian company based in Botticino, Brescia, specialising in high-quality circular knitting machines for premium socks, including sport and medical segments. Founded in 1958 by Giovanni Busi, the company made its mark with the BREBUS device, an innovation that allowed women’s stocking machines to be converted into sports sock machines.

This pioneering spirit continued in 1967 with the design of Busi’s first sock machine, beginning its specialisation in true rib knitting. By 1973, the company had expanded beyond Italian borders through a key partnership with a distributor in North Carolina, USA. In the years that followed, Busi embraced the electronic revolution, launching its first machine with electronic patterning in 1986, and then moving to fully electronically controlled machines in 1990.

1998 was a turning point with the acquisition of the Lin-Toe patent licence, the first market technology for toe closing. In 2005, Busi perfected its linking system for point-by-point toe closing. Then in 2009, Busi patented its Twin Layermachine for double-layer socks. That same year, the FIGC approved the use of a football sock made with this technology, strengthening Busi’s standing in the sports sector.

In 2013, the company entered the medical field with certified graduated compression sock machines. A testament to Busi’s constant commitment to innovation, in 2023 a sock made on the Twin Layer machine won the ISPO Innovation Award.

Speaking to Greencompany about the technological edge of Busi’s machinery, CEO Catina Busi explained that the company’s knitting machines deliver unmatched versatility in the textile sector. They allow for true rib, complex patterns, double fabric, and graduated compression socks - essential for medical applications - with a level of integration and flexibility traditional machines cannot match.

In line with its innovation drive, Busi recently partnered with Canalair Engineering to boost production efficiency and create healthier workspaces. By integrating Canalair’s air treatment systems, dust is reduced, ventilation improves, and purified air recirculation cuts energy consumption. This extends machine lifespan, reduces downtime, and enhances operator well-being.

Busi’s commitment to environmental sustainability began in 2011 with the installation of its first 83 kWp solar system, later joined by another 32 kWp system in 2024. These investments have significantly lowered the environmental impact of energy use. Busi also prioritises recycling materials within its production cycle, recovering waste and managing industrial scraps responsibly.

The company’s long history includes meaningful recognition that goes beyond mere awards. In 2009, during the global crisis, Busi received two major acknowledgements that strengthened its resolve. The FIGC officially approved a football sock made with the patented Twin Layer machine, consolidating Busi’s leadership in sports. That same year, Pope Benedict XVI sent a moving letter of thanks after Busi produced customised socks for His Holiness, a gesture that touched the entire community. In 2019, the Municipality of Botticino honoured founder Giovanni Busi by naming the company’s street after him - a tribute to his vision, courage, and contribution to the region.

Busi’s sustainability journey is supported by services such as Aceper’s Solar monitoring system, which has proved invaluable for keeping their solar installations efficient and avoiding financial losses from undetected faults.

Looking ahead, Busi is determined to invest in process automation to boost efficiency and precision. As Catina Busi points out, the humble sock is becoming a protagonist of daily comfort and wellness, evolving from a simple accessory to a vehicle for smart functionality. One example is the collaboration with Soccerment, whose XSEED shin pad integrates AI technology to collect performance data for athletes. Busi’s Twin Layer machine creates a customised pocket in the sock that perfectly accommodates the XSEED, ensuring comfort and stability while enabling smart data tracking - an example of how Busi is combining advanced knitting with wearable tech.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more