Tech start-up Smartex joins C.L.A.S.S. ecohub

The system uses Computer Vision and Artificial Intelligence and Smartex says it can be easily incorporated into knitting machines.

23rd November 2020

Knitting Industry

|

San Francisco, USA

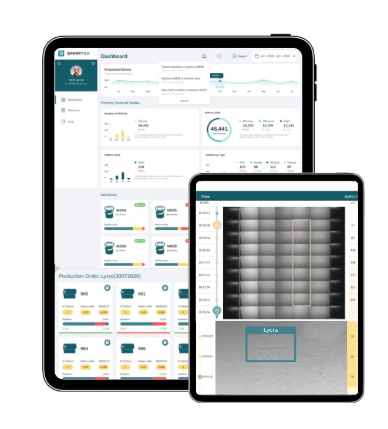

San Francisco based Smartex, has announced the launch of Smartex-V1, an ”‹advanced camera vision system that ”‹the company says, reduces defective production to close to 0%”‹ in circular knitting machines, including elastane faults, yarn thickness, holes, needle defects, and more.

Smartex’ camera inspection system is said to be able to reduce the production costs of knitted fabrics manufacturers by detecting and stopping the production machines on detection of faults. The system uses Computer Vision and Artificial Intelligence and Smartex says it can be easily incorporated in knitting machines.

Smartex-V1 also provides automated insightful productivity and quality reports, real-time production monitoring via the internet, and it registers and stores 100% of production data for full transparency and traceability, an opportunity that Smartex says, has never existed before.

Elastane defects

Elastane defects are one of the most difficult to detect in circular knitting. However, the Smartex-V1 inspection system is able to detect in real-time, any defects that occur during the production of elastane fabrics, as well as intervene in the production process, thereby avoiding waste due to periodic defects on fabric rolls.

With 10+ years of textiles experience, the Smartex team was selected by Forbes for its 2020 list of the 30 most impactful entrepreneurs in Europe

“One of the defects that present the most challenges is the elastane defect,” Smartex says. “Commonly, this defect goes unnoticed until the dyeing stage, resulting in waste of resources. Once a periodic defect is detected, the knitting machine stops the production so that the problem is promptly fixed without causing further damage. In case of singular defects (such as holes, oil spots, contamination points, etc), the system provides a stoppage option, XY roll coordinates, automated online dashboards, and quality reports of the rolls, machines, employees, and the entire factory plant,” the company says.

“Smartex’ innovative technology helps our company every month by increasing production, improving quality and transparency in the supply chain.” says Eng. Mario Jorge Silva, CEO at Tintex Textiles S.A., a leading Portuguese circular knitted fabrics producer.

Tintex is a leading textile company in Europe, known for high-quality standards in knitting and dyeing processes. The company reports direct benefits from Smartex’ technologies, including a monthly average of seven textile rolls saved per machine and a monthly average of 28 defects avoided, many of them periodic and repeatable capable of damaging full rolls.

Significant funding

Based in San Francisco, USA, Shenzhen, China, and Porto, Portugal, Smartex has attracted significant funding from funders focusing on”‹industrial technologies. Some examples include Momenta Ventures, DCVC, Spider Capital, SOSV, ”‹Cindy Bi (General Partner at CapitalX) ”‹and Fashion for Good, a global initiative supported by C&A, adidas, Kering Group, PVH, Stella McCartney, Target and Zalando. The European Commission has also recognized Smartex’ technologies as fundamental for industry 4.0 projects in textile factories, to better manage quality and efficiency, whilst reducing waste and time and avoiding late inspection after fabric rolls have already been produced.

Recognised by Forbes

With 10+ years of textiles experience, the Smartex team of founders was selected by Forbes in its 2020 list of the 30 most impactful entrepreneurs in Europe. “Our most recent partnership is with Intratess, a major textile supplier of the Kering Group which owns major fashion houses like Gucci and Balenciaga, who is adopting Smartex solution to bring textile waste in their factories to near zero,” concludes Smartex.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more