KnitMesh invests in world's largest wire knitting machine

Knitted wire mesh improves efficiency in hydrogen electrolysis systems.

4th November 2025

Knitting Industry

|

Greenfield, North Wales, United Kingdom

KnitMesh Technologies has been recognised in a new white paper by the German Aerospace Center (DLR) Institute of Engineering Thermodynamics, highlighting the company’s knitted wire mesh as a high-performance solution for porous transport layers (PTLs) in green hydrogen production. The study demonstrates how PTL design directly affects the efficiency, durability, and cost-effectiveness of water electrolysis systems - a critical technology in the transition to renewable energy.

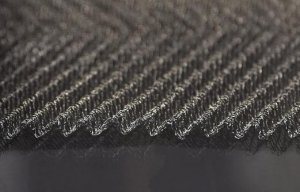

In controlled single-cell tests (4 cm², 1 M KOH, 60 °C), DLR compared a KnitMesh Technologies knitted wire mesh PTL against a standard configuration. Results revealed that the knitted mesh increased current density by 33%, reduced cell voltage by 74 mV at 2 A cm⁻² and ensured more uniform compression across the active area. It also enhanced gas transport for faster bubble removal while maintaining strong electrical and thermal conductivity with excellent permeability.

These findings, the company says, confirm that knitted wire mesh PTLs can outperform conventional materials under real-world operating conditions. Acting like a precision-engineered spring, the mesh adapts under compression to evenly distribute clamping forces and sustain consistent contact with the catalyst layer. This flexibility improves both performance and long-term durability of the membrane electrode assembly (MEA) - a key component of hydrogen electrolysers.

The study also highlights the mesh’s ability to facilitate efficient two-phase flow. By allowing gas to escape freely while maintaining continuous electrolyte access to the reaction sites, the structure enhances electrochemical efficiency and system stability.

Another advantage lies in the customisability of knitted wire mesh. Parameters such as porosity, thickness, and filament diameter can be precisely tuned to achieve the desired balance of conductivity, permeability, and elasticity for specific stack designs. This level of control is difficult to replicate in rigid or brittle PTL materials, making knitted mesh an attractive option for next-generation hydrogen systems.

“This study from DLR supports what we have found in our own development work,” said Craig Jones, Engineering Manager at KnitMesh Technologies. “Knitted wire mesh provides a unique combination of flexibility, conductivity, and permeability, which can deliver significant performance improvements in electrolysis. As the hydrogen industry continues to expand, innovative materials such as ours will be essential in increasing efficiency and reducing costs throughout the value chain.”

Founded in 1957, KnitMesh Technologies is a leading manufacturer of bespoke knitted wire mesh components for industries worldwide. The company’s products - including gas diffusion and porous transport layers - play a vital role in the hydrogen sector, improving the efficiency and resilience of energy systems. Headquartered in the UK with a secondary manufacturing site near New Delhi, India, KnitMesh combines engineering expertise with ongoing material innovation to support sustainable energy solutions.

Read the white paper:

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more