Kasey Hatch, the designer behind Katch.Sport graduated from NTU in Summer 2019, and after a whirlwind show at New Designers 2019, we caught up with her to learn more about the innovative work she presented within her collection OSTEO.FIT.

Studying her BA in Fashion at Coventry University, Kasey chose to create a sportswear collection for her final major project. Focussing on the aesthetics of her project and celebrating her creativity, she developed her pattern cutting skills. It was during her MA that she decided to focus on the grass roots of her work and engineer the fabrics to form her silhouettes.

Kasey explained: “During my MA I wanted to progress into making the fabrics that I would be using to make the garments. I also wanted to develop garment construction using zero waste methods.”

Having focussed on fashion for three years, it was only during her MA that Kasey was able to give the materiality of her designs the true attention it deserved. Fascinated by the chance to experiment again with textiles, fibre and yarn, she was also attracted to the chance to explore innovation and research at Nottingham Trent University, on the MA Textile Design Innovation Course. Keen to learn alongside other creative, forward thinking and innovative students, Kasey embarked on her MA, and OSTEO.FIT took formation.

Osteoporosis is a medical condition, which impacts over 3 million people in the UK. It is a medical condition, which causes bones to become brittle and weak, with much higher risk of fractures and breaks.

Inspired by personal experience and a unique approach to research, Kasey’s fundamental instincts as a problem solver led her to dedicate her MA to tackling the problem of lack of inclusion within sports for individuals with Osteoporosis.

Why did you choose to focus on Osteoporosis and solving the problems within this field?

“I am a problem solver, I really wanted to give the project a purpose. I think with everything environmentally that is happening currently, making product for the sake of making products just isn’t good enough anymore, I wanted to create something that could make a difference to even just a handful of people. I started by focussing on those who may have limitations with exercising, and then chose specifically to research into Osteoporosis, as a condition that a family member has, which has an effect on how she is able to move whilst engaging in physical activity. It also became very obvious to me whilst researching that there is very little in the way of products to help those who don’t fit into the ‘young fit gym goers’ demographic, so I saw a gap in the market that I wanted to fill.”

What were some exciting or unexpected parts of your project?

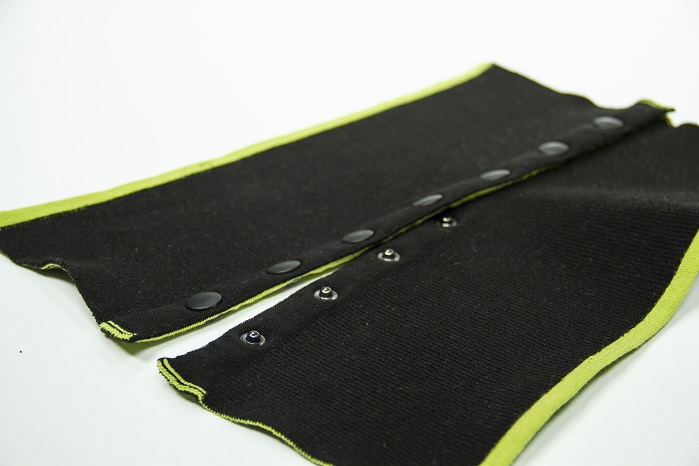

“Knitting was always unexpected! Trying to mix techniques on the power knitting machines was a challenge, and things didn’t always go to plan. Trial and error played a huge part in some of my idea development, but I think that was the most exciting part, trying to achieve the product I had designed on paper.”

What machinery did you use?

“Mainly I used the ADF 32W multi-gauge Stoll knitting machine to produce most of my product and the 12 and 16 gauge linkers. The facilities at NTU are quite impressive. The opportunity to use industry standard machines to produce your work during your time as a student is important to achieve industry standard products, and to gain and understanding of machine capabilities before going to work in industry. I can’t say enough good things about the knit technicians, they are unbelievably helpful and good at what they do, my project just wouldn’t have been realised without them.”

How important was yarn choice?

“Yarn choice was a huge part of the project, I wanted to keep the products as natural and sustainable as possible. The main yarn used was a SeaCell / Merino blend yarn, which I was sponsored by Smartfiber and Inovafil. It’s biodegradable, lightweight, soft and breathable making it perfect for sportswear application. Crucially, this exciting yarn also holds the ability to transfer essential minerals for bone health and growth from the fabric to the skin, helping those with Osteoporosis.”

When discussing the challenges faced by her yarn choices and material palette, Kasey further explained: “It was also necessary to use an elastane yarn, to give products elasticity as the natural elasticity in the merino just isn’t enough. The original idea was to be using recycled elastane, but as it’s such a new product it is difficult to source, so I did have to compromise and use elastane.”

How does your textiles specifically help those with Osteoporosis?

“The idea is, as these women are exercising, building up bone and muscle strength, they are also absorbing nutrients to treat their condition. The SeaCell yarn transfers the minerals for bone health and growth from the fabric to the skin, catalysed by the skins natural moisture and sweat.

I also have been developing products to absorb and dissipate impact energy in common fracture areas in order to minimise damage and prevent fractures from a fall. As well as the practicalities, I want to produce products that these women want to wear, so I have had a lot of input from Women with Osteoporosis, giving me some insight to what they want to wear whilst exercising and what is the most important aspect of the clothing for them, so the products have been designed to suit the needs of the consumer both aesthetically and technically.

During the process of the project I had got in touch with charities and hospitals to try to get some help with testing, however, they were unable to help at the time. That is something I am currently looking into; I want to have my products medically tested on women who have Osteoporosis to see how much of an impact my products can make. However, I do have test results and certificates from Smartfiber that confirms that the yarn can transfer these minerals to the skin. Whilst I did not directly collaborate with anyone, I did utilise a user-centred research approach and used co-design with my consumer.”

Speaking further with Kasey it became clear that it was a circular research led design process between herself, real women living with Osteoporosis, her spinners and the charities that advised her. Scientific accreditation and medical corroboration are the next steps she hopes to achieve.

What have you been up to since New Designers? What are your plans for the next year?

“Since New Designers I have finished my MA and had another Exhibition at NTU. I am currently looking for a job in sportswear design and material development and thinking about undertaking a PHD in the future to continue my research.”

Studying Knitwear Design, it is certainly hard to stand out from the vast, varied and exciting competition. At New Designers, Kasey’s work did just that. As well as challenging materiality, silhouette and garment design aesthetic, she took on a wider problem. By engaging with another side of textiles, combining the medical sector with sportswear fashion, Kasey created a body of work that pushed the parameters of what knitwear designers can achieve. To have achieved such a compelling outcome at such an early stage in her career is commendable. Inspirational moves such as these broaden the horizons and expand the fields of opportunity for young, new designers. No doubt Kasey is set for an exciting year as a new graduate. It will be interesting to follow Kasey’s development and the progression of OSTEO.FIT as she embarks on her new chapter in industry.

Further reading

The Royal Osteoporosis Society is the UK’s national charity for Osteoporosis.

New Designers: Seven knitters to watch

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.