The 8th of October 2020 was World Circular Textiles Day, an event marked with a webinar to introduce the collective vision of achieving full circularity by 2050. In celebration of the diverse group of people involved in developing this ambitions goal, the event recognised the designers, policy makers, scientists, campaigners, and all individuals who have collaborated so far. With signatories across industry, cooperation and collaboration is gaining momentum.

Circular Design is not without controversy, and this ‘elephant in the room’ was addressed outright. WCTD began by actively inviting the scrutiny of these alternative viewpoints, to problem solve their method. Extending the invitation for involvement across the breadth of lenses involved, WCTD encouraged interruptions to the circularity conversation, so different perspectives can intervene and make an impact.

Fuelled by the belief that envisioning the end point facilitates planning for the journey there, WCTD introduced this dynamic and evolving challenge through their phased approach. Leverage points such as technology, infrastructure and legislation are to be assessed whilst working backwards from the 2050 end goal.

What Is Full Circularity By 2050?

Successfully achieving full circularity is defined for WCTD as a time when there is “dignity, equity and equality”. Further, it is a time when “shared textile resources in the form of products and raw materials are kept in continual circulation, and virgin resources are no longer needed”.

The plan charters the way through what will inevitably be a challenging path, and endeavours to become a “living, breathing time capsule, charting the progress and momentum over the next 3 decades”.

When the panel were asked “Why 2050, why not sooner – or later?” their response was optimistic, explaining an early ‘arrival date’ would be wholly welcomed if it came in the right way. Setting a 2050 deadline gave realistic time to effect change whilst instilling a sense of urgency, inspiring the vigour to act now.

Introducing what WCTD means for the circular economy, Gwen Cunningham of the Textiles Programme Circle Economy informed viewers that only 8.6% of production is currently circular. By 2050, this must be 100%. Some might suggest this is unrealistic, but the sense of urgency sparked by this tight deadline is entirely intentional.

Dr Kate Goldsworthy of the Centre for Circular Design at UAL shared the excitement of the COCD at being a part of accelerating this mission. She explained the problems to be solved are not only material but systems and mind-set related. Here lies the importance of mass collaboration, inviting debate and expertise from individuals and organisations of vast and varied backgrounds.

Dr Goldsworthy particularly focussed on the tipping point at which the industry now stands, as technology is creating the potential for supply chains to move towards regenerative and renewable sources. Mind-sets, she explained, must catch up with this advancement.

Processing Hub Proposal

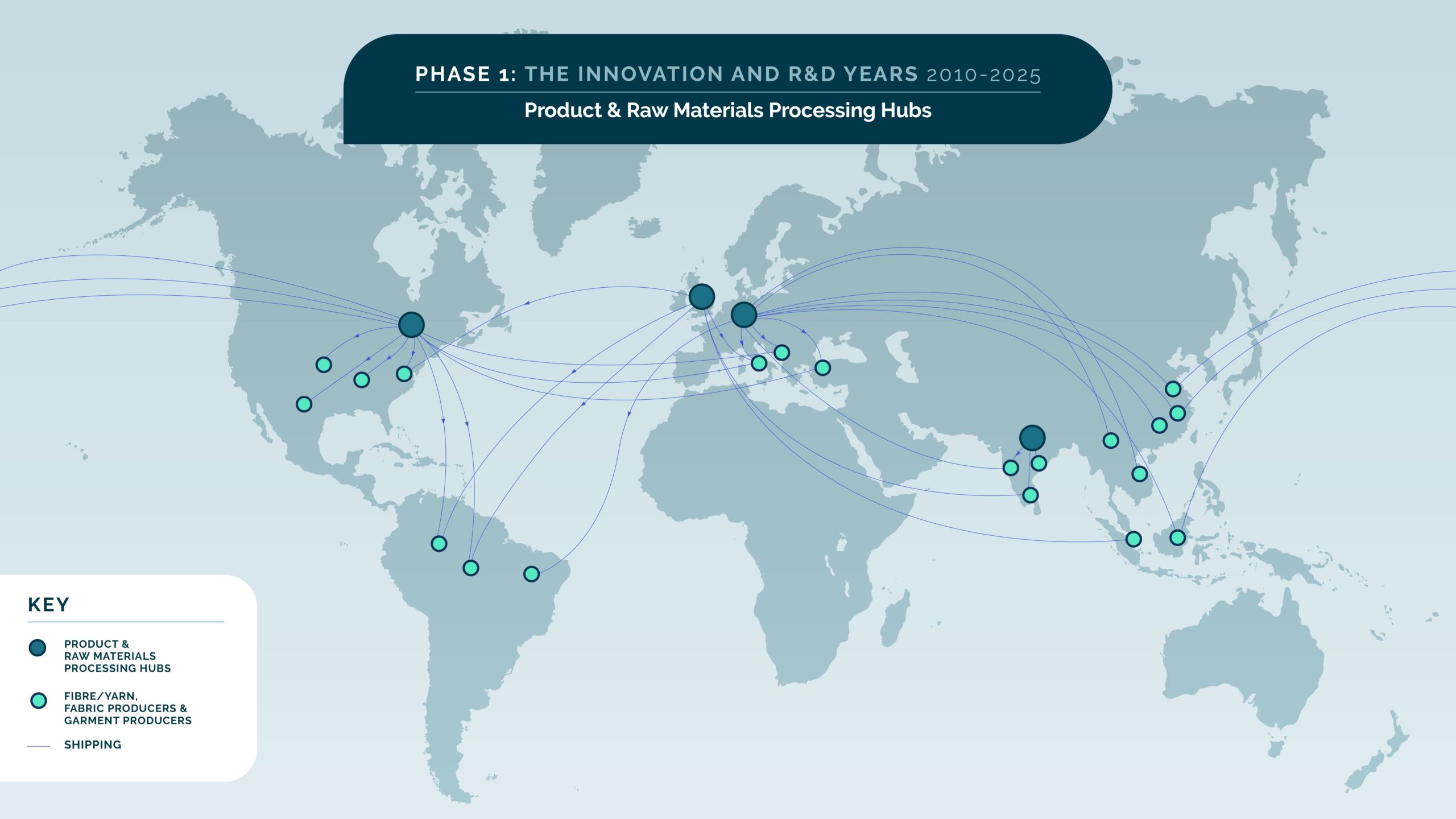

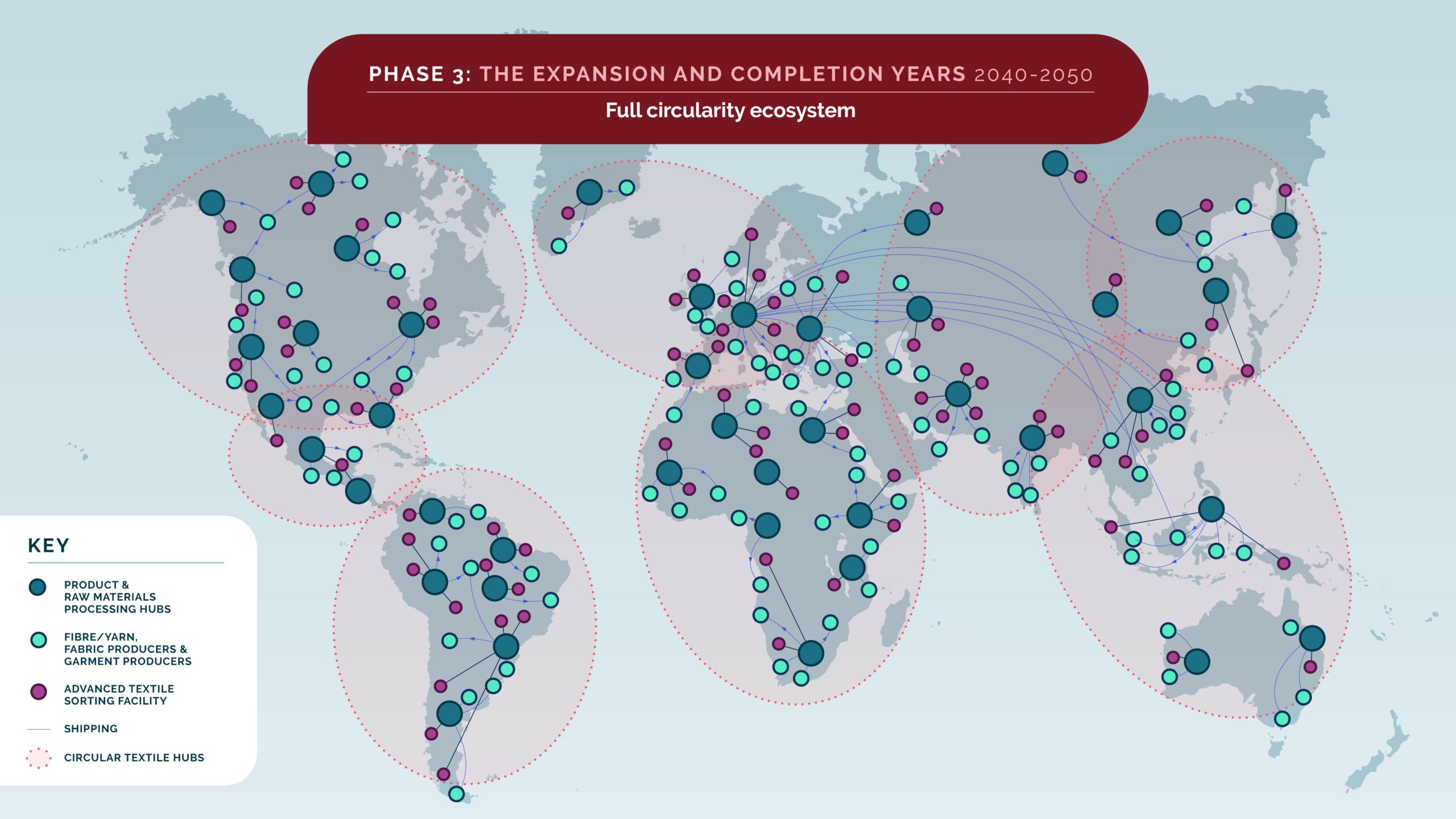

Fundamental to the WCTD plan is the creation and implementation of their proposed ‘product and raw material processing hubs’. By 2050, these would be rolled out across the globe, localising textile sorting by region.

The prototype of this advanced textile sorting facility is the next generation of fibre recycling. Put simply, textile waste would be locally collected and sent to the nearest regional hub. Here it would be separated manually into re use and re sale markets. Unlike current systems, garments with no second hand value would be introduced to a highly automated system regulated by robots, where fibre detection technology would further separate the textiles into ‘fibre content buckets’ of blends or mono fibres. These could be sold to regenerative markets and under go fibre to fibre recycling.

This innovation requires more than just engineering and technology expertise. An extreme growth in knowledge of material flow systems is required. The market drivers for such innovation are not yet achieving this lower cost, higher output sorting method. But this ‘hub’ proposal is crucial for the future of circular textiles within the WCTD phased vision.

Looking Into The Lens Of 2050

Phase 1: 2010-2025

These are the ‘Innovation and R&D’ years. Raw materials in this first phase may need to be shipped to high volume production regions, with a shift introduced in the flow of materials. Rather than textiles going to landfill and incineration, collecting and reusing resources in a more intelligent way will develop. Digitisation, product passports and policy change will happen, bringing the puzzle pieces together for Phase 2.

Phase 2: 2025-2040

These are the ‘Infrastructure and roll out years’. Global roll out of the hubs will be introduced, as collection systems feed into more localised recycling hubs. Additional advanced textile sorting facilities will be introduced to handle the increased global textile collection. Within the regions of these hubs, players within the supply chain will gain momentum, setting up mills locally to process the fibres. Global legislation must keep up with this phase, which should see the core roll out of this new industry.

Phase 3: 2040-2050

During these ‘Expansion and completion years’ roll out across every continent will take place, creating efficient flows of resources in line with planetary boundaries. Diversity will flourish as local and regional hubs provide work and opportunities.

Increased awareness of sustainability runs throughout each phase, widening consumer and industry endorsement. During the webinar, the WCTD panel stressed that their framework is open to development, but for now this forms the ‘bones’ of the mammoth task.

Trouble Shooting The Plan

With current textile manufacturing ‘hubs’ formed in specific regions currently, the introduction of new hubs across Europe and within areas without textile industries is a big ask. The thinking here was explained by the panel, sharing that moving to a regional plan would generate localised communities.

Social fairness under the profit of capitalism was also discussed, and whether circularity helps or hinders diversity, decent work and inclusivity. Whilst there is anticipated to be a huge volume of new jobs created within the system, jobs within systems upon which whole communities rely would be lost and not necessarily replaced. The impact of the removal of industry from parts of the world, which rely heavily on it, must be seriously considered.

The question of the role of polyester in the plan was also posed to the panel. Dr Kate Goldsworthy explained that, “like it or loath it”, polyester plays a part in this new landscape. But the quantity of polyester already in circulation above ground is huge, so focussing on collecting existing polyester into the cycle and making it regenerative rather than making any more is the key.

The panel acknowledged there are no total answers, but their work ahead resolves to tackle these challenges, with a ‘call to arms’ for partnerships in new revenue, new taxation models and new concepts, which can facilitate just and fair change for the better. This must be a conversation of social inclusivity, not only materiality, all the way to 2050.

You can watch the webinar in full here.

The full- circularity retrospective 2050 can be viewed here.

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.