HKRITA Green Machine wins award

The development of tailored needles for special applications is one of the strengths of Groz-Beckert.

29th November 2019

Knitting Industry

|

Albstadt

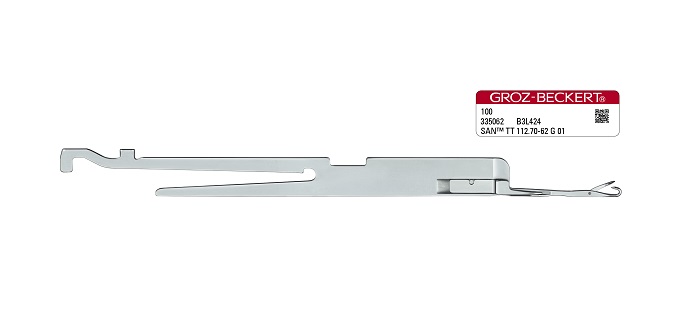

SAN TT. © Groz-Beckert

The development of tailored needles for special applications is one of the strengths of Groz-Beckert, a leading German specialist in needles and spare parts for textile machinery. One example from the flat knitting sector is the special application needle SAN TT.

Every innovation starts with the idea of creating something special, something new or something better,” the company reports. “At this point, the implementation is still far in the future. Existing technologies are often not the optimal solution for a newly developed application. With our experience and our expertise, we are able to create the technical requirements not only for standard cases, but for special cases too. As development partners, we thus contribute to the implementation of your idea.”

A field with high potential for new and further developments, which seemed unimaginable until recently, is technical textiles. New products are being created here, new production methods, as well as constant new challenges. In order to meet these challenges successfully and to make use of the innovation potential, a manufacturer needs the right tool. “One development that resulted from a specific application is the special application needle SAN TT,” the company continues. “SAN stands for special application needle and TT stands for technical textiles.”

Earlier, the company already reported on the production of shoe uppers on flat knitting machines in the field of technical textiles. Tight loops with a high course density guarantee dimensional stability of the shoe. Extreme tractive forces are created during the production of these loops, however, which place high demands on the stability of the needle hook. In this application, multi-thread continuous filament yarns are used, which increases the risk of cut filaments.

Shoe uppers. © Groz-Beckert

If the yarn is damaged in this way during processing, the surface of the product becomes hairy. The special challenges of this and other applications with comparable requirements therefore include creating a perfect loop structure on the one hand and the durability of the knitted elements on the other.

The company’s special application needle SAN TT 112.70-62 G 01 in gauge E 7.2 was specifically designed to optimise the production process in these applications. With its narrow latch head, the first version of the new product range is ideal for producing tight loops. “The increased hook stability is the answer to the high tractive forces,” the manufacturer explains. The adapted spring-loaded latch function and the anti-shear effect are designed to guarantee perfect cast-off of the loop and prevent filaments from being cut during the closing action of the latch. This solution concept can be adapted for all the latest flat knitting machine technologies.

“For a customer, the use of the special application needle SAN TT means increased productivity through reduced needle consumption and reduced machine downtimes. The prevention of the shearing effect, the optimised cast-off and the adapted spring-latch function ensure a perfect loop structure,” Groz-Beckert concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more