Pushing the envelope with Textile-Circuit

Karl Mayer’s smart shirt with integrated sensors is opening up new applications

9th December 2019

Knitting Industry

|

Obertshausen

Presentation of the smart shirt at the ITMA 2019. © Karl Mayer.

Since 2018, Karl Mayer has been developing highly efficient technology for producing functional warp knits with electrical conductivity under the concept of Textile-Circuit and says it is setting the trend in electronic wearables.

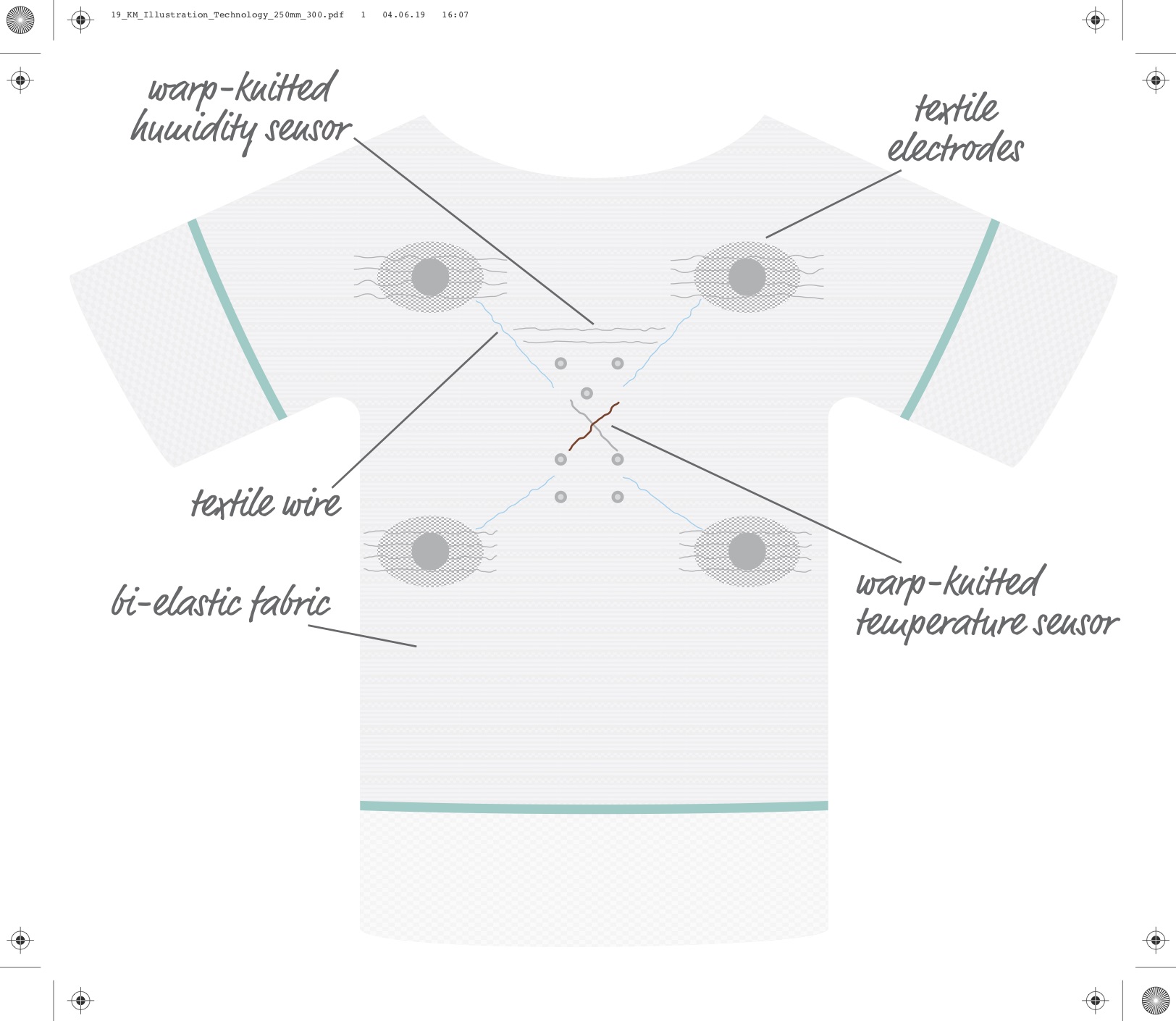

The special feature of Textile-Circuit is that conductive yarns can be incorporated directly into the fabric during the warp knitting process, and they can be positioned in any location and in any design. Functional elements, such as sensors, conductors and coils, can be placed exactly where they are needed. No additional production sequences are needed whatsoever, and the textile characteristics are fully retained.

T-shirt with measuring functions

In the first stage of the development work, comfortable cuffs for remotely controlling robots, and textile charging stations for the inductive charging of smartphones were produced. A smart shirt with measuring functions was produced during a follow-up project.

This functional garment was effectively demonstrating the possibilities offered by Textile-Circuit to a wide audience at ITMA 2019. It measures the heart rate, the moisture levels in the textile, and the temperature of the skin. The sensors needed to do this are integrated into the textile in a single step and transmit their recorded signals via an insulated conductor for processing in a mobile electronic unit.

The results can be called up on mobile devices via Bluetooth. The values measured for a cyclist were being displayed impressively on a huge display at ITMA 2019. As well as delivering functionality, this smart shirt also provides exceptional wear comfort. The flexibility of the conductive surfaces and the bi-elasticity of the fabrics deliver exceptional freedom of movement, and the textured polyamide filament yarns processed provide a soft touch.

New market potential

The performance of Textile-Circuit is opening up completely new market opportunities. “I talked to users from a wide range of sectors during the course of working on the project and attending trade fairs. I was surprised at the wide variety of ideas they came up with for using our textile sensor systems,” explains Sophia Krinner. The Product Developer, Textile Technology, at Karl Mayer sees a huge potential for them, especially in the sportswear, workwear and healthcare sectors.

Sophie Krinner also said that she had had many enquiries about buying the conductive, warp-knitted textiles Encouraged by this feedback, she is carrying on with her development work. Further stages will focus on improving the finishing of the textile and optimising the sensor technology. More information on Textile-Circuit will be available on stand 408 in hall C2 at ISPO Munich, which is taking place from 26 to 29 January 2020.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more