Mandarin opens Portugal hub

Editor’s View

Innovating in flat knitting since 2011 with Italian technology made in China.

12th July 2023

Billy Hunter

|

Milan

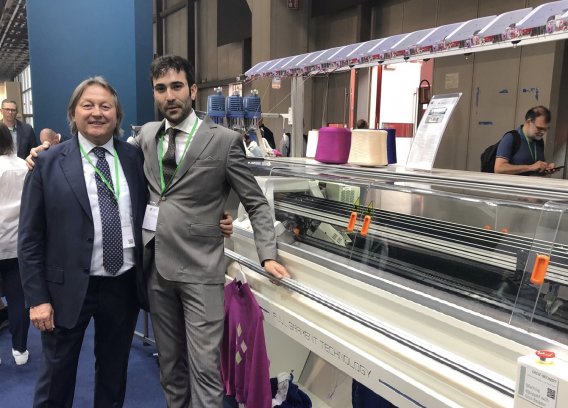

Italian company Mandarin Knitting Technology showcased a wide range of advanced computerised flat knitting machines at last month’s ITMA 2023 in Milan. The company’s ‘designed in Italy, made in China’ technology attracted a lot of attention, standing out amongst the small/medium sized machine builders.

Mandarin was born in 2011 in Conegliano, near Treviso in Northeast Italy’s Veneto region, an area made famous for knitwear manufacturing by industry giants like Benetton and Stefanel. The company was founded by current CEO Sante De Pecol, who after more than 40 years in the flat knitting machinery sector, decided to create his own machinery project and to industrialise it in China’s Zhejiang province, an important stop on the ancient Silk Road famous for its textiles and now electronics industries.

A passion for innovation and a love of knitwear are the cornerstones of the company, which is dedicated to the research and development of technological innovations, capable of overcoming the limits that other current technologies present on the market impose. The aim is to ‘create technical and visual marvels’ with the highest precision and quality.

Mandarin says it focusses on quality and started production in 2011 with its well-known F30-3S SYF flat knitting machine, a machine fitted with motorised feeders. The company claims to have more than 1000 machines running in Italy alone, with many operating in the nearby Veneto and Emilia Romagna, and other areas of Italy. Mandarin has three offices in Italy – its headquarters in Treviso, and two service centres in Pistoia (Tuscany) and Napoli in the south. In addition, it has service centres in Spain, Portugal, Brazil, Mexico, Romania, Morocco, Bulgaria and the United States.

Mandarin flat knitting machines are making knitted products for many famous European brands including Hermes, Gucci and Louis Vuitton. Even the now iconic Balenciaga Speed Runner shoe upper is made on Mandarin machines.

Full Garment Series

An interesting machine on show at the Mandarin booth at ITMA was the 7.2-gauge model FG-372 SYF from the company’s Full Garment Series. Seam free complete garments are knitted using the alternate needle or half gauge knitting technique on the FG-372 SYF, reducing labour, shortening the production cycle, and reducing production and management costs.

Mandarin’s Full Garment Series machines are available in gauges 6.2, 7.2, 8.2, 9.2 and 10.2 in a 72-inch needle bed configuration. The FG-372 SYF on show was a single carriage three system knitting machine with a maximum knitting speed of 1.6 m/s.

According to Mandarin, its SYF Technology (Smart Yarn Feeders) represents one of the bedrocks of the evolution of its machinery, and this technology is applied to the Full Garment Series. Driven by transmission belts and no longer by the carriage, the 16 motorised yarn guides on four rails allow special processes and optimised production times.

Takedown comes in the form of ‘high positioned rollers’ close to the knitting zone (2 cm below), and sector-controlled sub rollers. Here, the traditional takedown roller is replaced by a smart flexible pulling device composed of several motorised blocks. It is possible to adjust the blocks individually in sections and zones via machine programming. This allows accurate localised control of pull down during complex complete garment knitting. Multi Sinker is a new sinker and independent control system that allows the adjustment of working parameters arbitrarily according to the working of each knitted course.

The FG-372 on show was fitted with SF-2 yarn storage feeders which to prevent yarn accumulation during knitting, ensure constant yarn tension, and to yield more uniform fabric density and thus improved appearance.

Ultra-coarse gauge

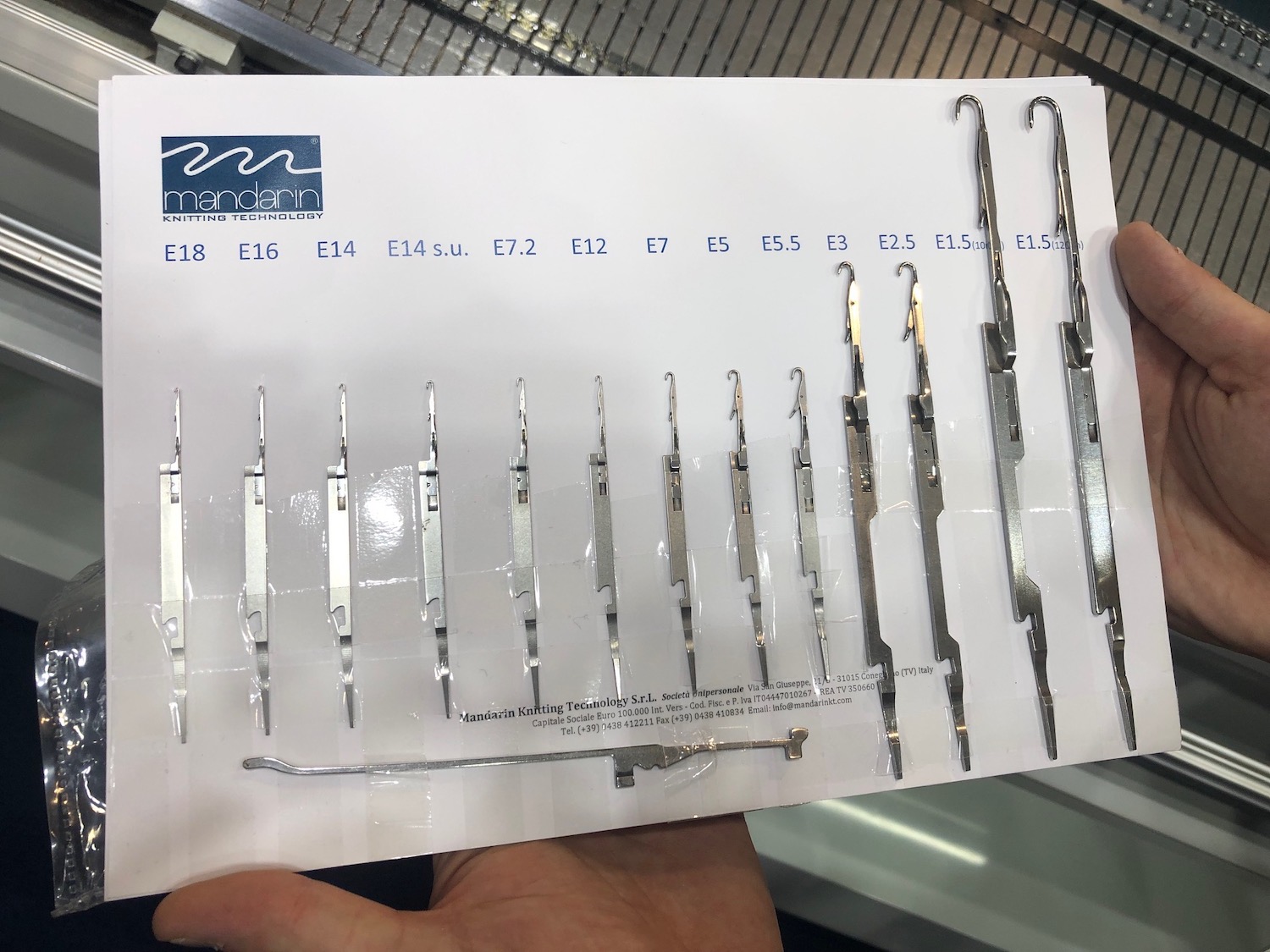

Mandarin manufactures flat knitting machines in gauges (needles per inch) 1.5, 2.5, 3.5, 5.5, 7, 12, 7.2, 14, 16, 18 and 20.

One of the most interesting machines on display was the F20 101 TD in 1.5 gauge. The machine on show was equipped with an extra-large hook 1.5-gauge needle, knitting in half gauge, where the final claimed gauge was in fact 0.75 gauge.

Mandarin’s head of marketing Niccolò Franchin told Knitting Industry that the machine is the world’s coarsest gauge flat knitting machine. Franchin also said that an Italian carpet producer was actually using the 0.75-gauge F20 101 TD machine to make rugs.

As well as ultra-coarse gauge knitwear, other applications for the F20 101 TD include interior textiles and industrial applications. The company produces Thick Design Series in gauges 1, 1.5, and 2.

Shoe uppers

Most flat knitting machine builders these days offer a specialised shoe upper knitting machine, and Mandarin is no exception. The company’s specialist machine is the model F30-3X SYF. Mandarin says it has a number of these machines running in Brazil, its current top market, where knitters are making shoe uppers for US drinks giant Coca-Cola.

The two and three system machines in Mandarin’s Shoe Upper Series – F30-3X SYF, F30-2X and F30-3X- are available in 36, 52 and 72-inch working widths and have a top speed of 1.4 m/s. Motorised yarn carriers are available on SYF models.

The 14-gauge s.u F30-3X SYF on show in Milan had an extra motor mounted on the carriage for the creation of reinforced areas – the independent tuck stitch feature allows the creation of more compact knitting for strengthened areas in the shoe upper, such as heel reinforcement. This eliminates the need for post knitting reinforcement using additional reinforcing materials.

The Shoe Upper Series is specifically manufactured for making shoe uppers, but it is also the model that Mandarin sells for the production of technical fabrics and medical garments.

Mandarin Knitting Technology is a company which really embraces technology and is one to watch for the future.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more