Shima Seiki Innovation Factory moves to Tokyo

By combining two different yarns between outside and inside, Shima is able to achieve multi-functional garments depending on the yarns used.

2nd February 2021

Knitting Industry

|

Wakayama, Japan

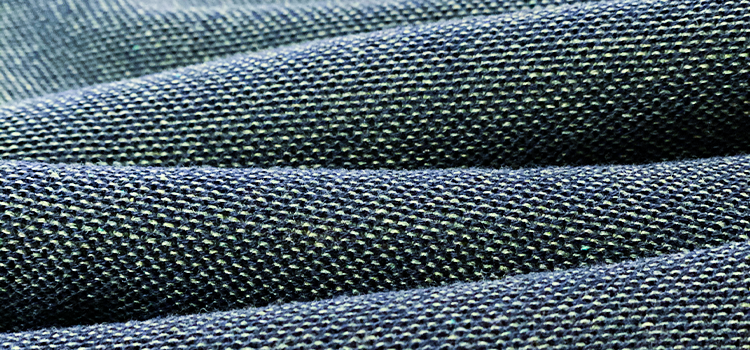

Leading flat knitting machine manufacturer Shima Seiki has developed a new knitting technique called AiryPique which adds bulk to its seam free WHOLEGARMENT knitwear products, which are normally naturally thinner, due to their single-layer construction. By combining two different yarns between outside and inside, Shima is able to achieve multi-functional garments depending on the yarns used.

The AiryPique knit technique enhances design capability by changing yarn colours on the inside and outside, allowing for a reversible design. The short sleeve sweater (pictured above) was made on the Japanese company’s MACH2XS15L machine in a 15-gauge texture. “We used Japanese paper yarn on the outside and antibacterial deodorizing cotton yarn on the inside, for a lightweight but bulky fabric,” the company said.

“The AiryPique knit technique was recently developed on our WHOLEGARMENT machines to improve the thickness and bulk of fabric whilst being lightweight,” explains Shima. “This long-sleeve pullover was made on our MACH2XS15L machine in a 15gg texture. We differentiated colours between the sleeve and body and used 52% upcycled cotton and 48% recycled polyester yarn to propose a sustainable garment.”

“The AiryPique knit technique with the right yarn allows for increased heat retention as well,” Shima adds. When knitting with wool, the AiryPique structure tested 34% warmer compared to a traditional single jersey in the exact same yarn, it added. “This long-sleeve pullover was made on our MACH2XS18L machine in an 18gg ultra-fine texture. We used wool on the outside and extra-long-staple cotton on the inside, for a more comfortable touch, while providing more heat retention through the lofted AirPique Structure,” Shima concluded.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more