Shima Seiki at the 3D TECH Festival

Amongst the exhibits will be the Japanese company’s brand new N.SSR 072 computerised jacquard collar machine that can produce shaped collars efficiently.

22nd February 2024

Knitting Industry

|

Wakayama, Japan

Leading computerised flat knitting solutions provider Shima Seiki is exhibiting at the Knit-Tech 2024 Exhibition in Tiruppur, India, in cooperation with its partner Universal MEP Projects & Engineering Services Ltd., next month (1-4 March 2024).

As Tiruppur is known as the knitwear capital of India and is home to a vast knitting industry consisting mainly of circular knitwear exports of cotton products. Shima Seiki will be introducing the latest computerised flat knitting equipment to this market as proposals for sustainable production through innovative shaping technology and the latest digital solutions.

Shima Seiki’s line-up at Knit-Tech is headed by its workhorse N.SSR 112 garment shaping machine in 14 gauge. N.SSR 112 offers leading technology in an economical yet reliable package. Featuring industry-leading innovations such as the R2CARRIAGE, spring-type moveable sinker, DSCS Digital Stitch Control System, stitch presser, yarn gripper and cutter, and takedown comb.

Shaped collars

Made-in-Japan quality, reliability, productivity, user-friendliness and cost-performance combine to satisfy the high expectations placed on India's exports to the world's fashion industry, and for domestic consumption as well. Shown for the first time is Shima Seiki’s brand new N.SSR 072 computerised jacquard collar machine that can produce shaped collars efficiently based on computer-generated designs.

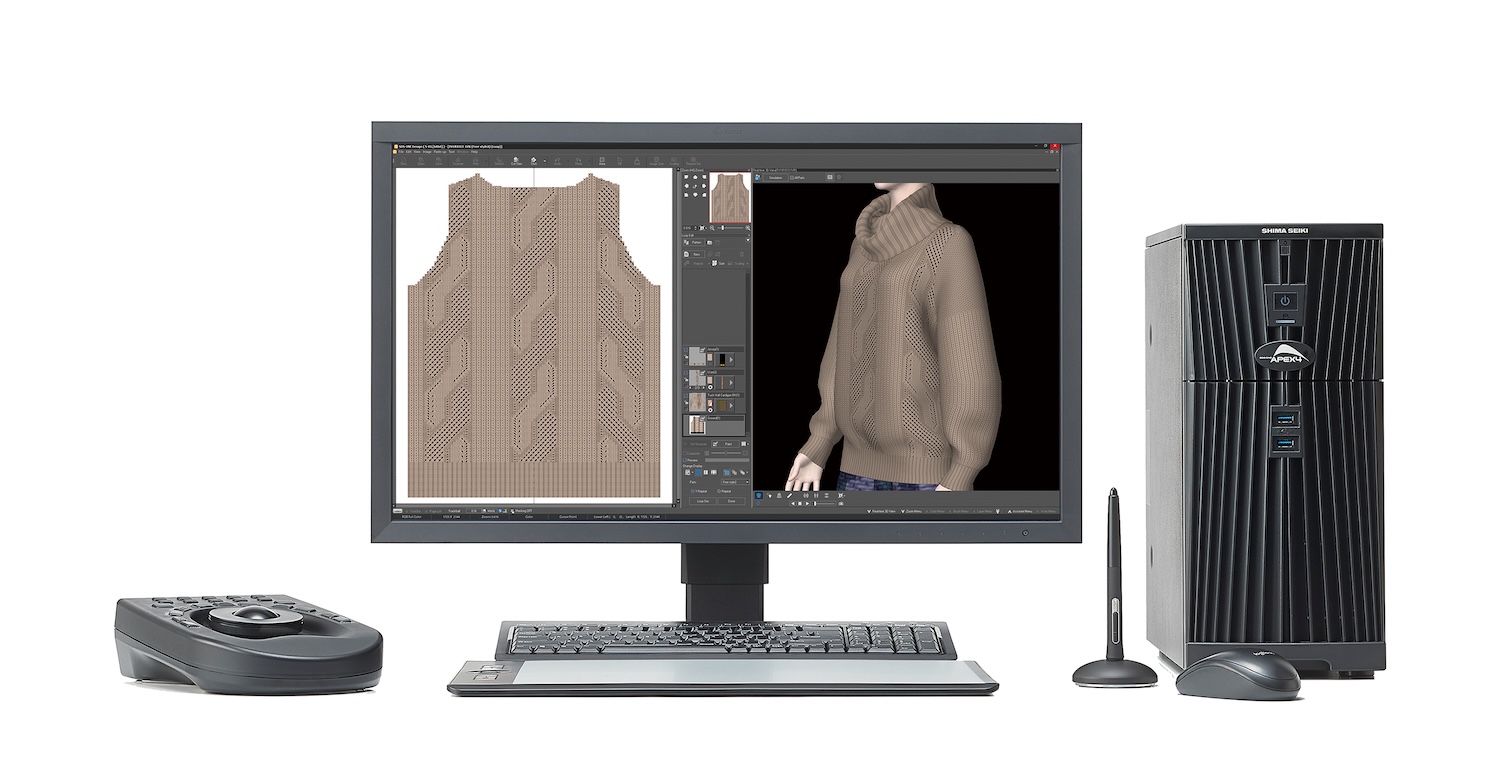

Design is demonstrated on Shima Seiki’s SDS-ONE APEX4 design system. At the core of the company’s Total Fashion System concept, it provides comprehensive support throughout the supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design, to machine programming, production and even sales promotion.

Especially effective is the way SDS-ONE APEX4 improves on the product planning and design evaluation process by replacing physical samples with digital prototypes. Based on photo-realistic simulations, these virtual samples minimise the need for actual sample-making, realizing significant savings in time, cost and material. In combination with WHOLEGARMENT knitting machines, virtual sampling realises a sustainable planning and production base that contributes positively to manufacturing transparency, which has become increasingly important for exports to conscientious consumer markets worldwide.

Knit-Tech 2024

Friday, 1st - Sunday, 4th March 2024

Hitech Tirupur Exhibition Centre Koolipalayam Ring Rd, Thirumurugan Poondi, Tiruppur, Avinashi, Tamil Nadu 641652

For further information please contact:

Universal MEP Projects & Engineering Services Ltd.

Textile Machinery Division Sales Headquarters 3rd Floor

Voltas House, No. 1413 Trichy Road, Coimbatore 641-018, INDIA Tel: +91 422-6619002

Email: [email protected]

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more