Spotlight on colouration at Performance Days Munich

Collection of 65 new reference fabrics marries high performance with sustainable gains.

13th March 2023

Knitting Industry

|

Munich

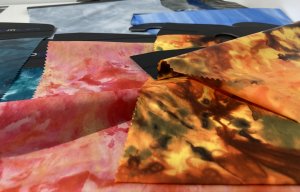

At this week’s Performance Days exhibition in Munich (March 15-16), Japan’s Asahi Kasei Advance is presenting its Autumn/Winter 2023/24 Ecosensor fabric collection for functional fabrics.

Around 97% of the collection of 65 new reference fabrics is made with recycled polyamide, polyester and polypropylene fibres, along with Roica EF, the recycled stretch yarn made from pre-consumer materials, and Bemberg, which is obtained from cotton linters through a closed-loop process that is transparent and traceable, ensuring certified credentials.

Bemberg recently achieved the OK biodegradable Marine certification, which guarantees the biodegradability of its products, as certified by TÜV Austria.

Knits

The collection also includes 17 Ecosensor knits with new and special quarter gauge knits have differing looks on their front and back faces thanks to a special knitting process. By using low gauges on the back face, these new fabrics can also absorb water and dry quickly as a perfect substitute of fleece fabric. Fabric ESS2-31440-2 is meanwhile produced on a double raschel knitting machine, which combined with a proprietary dyeing process and finishing techniques results in a new brushed texture without a brushing treatment, to help reduce microshedding.

“Season by season our global team is ever more determined to innovate with a responsible approach, in order to develop solutions that meet high-performance standards as well as measuring the impact and sharing the transparency and traceability of both the ingredients and the supply chain,” says Osamu Hashimoto, senior managing director of Asahi Kasei Advance.

Wovens

An interesting new development among the 40 new woven fabrics for sports is the introduction of the RespiGard membrane by Polypore, now an Asahi Kasei company. RespiGard’s pore structure is too small for water droplets to penetrate but jas a high porosity that allows for airflow and moisture evaporation. It is naturally hydrophobic, has a smooth and uniform surface and is also lightweight due to its high porosity. It is produced using a solvent-free manufacturing process with a low carbon footprint and is recyclable and perfluorocarbon (PFC) free.

Also new is a lightweight double weave fabric – ESS1-A8270-MDWR which offers stretch performance without the use of elastane.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more