Online Seminar: Sock and Hosiery Knitting

Company to showcase groundbreaking knitting innovations at ITMA Asia + CITME 2025.

21st October 2025

Knitting Industry

|

Albstadt, Germany

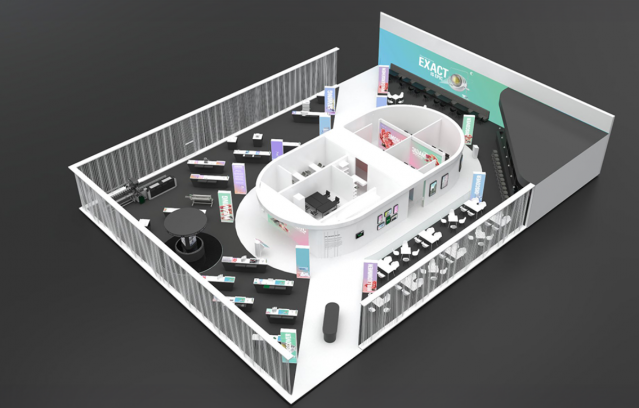

At ITMA Asia + CITME 2025, taking place from 28–31 October at the Singapore Expo, Groz-Beckert will put the spotlight firmly on knitting technology. The company’s display at Hall 5, Booth B301, will highlight next-generation solutions designed to boost efficiency, sustainability, and precision in knitting production across both circular and flat knitting sectors.

At the heart of Groz-Beckert’s knitting presentation is the new LCmax needle – a major step forward in energy-efficient knitting. Featuring an innovative wave-shaped shank geometry, LCmax reduces friction while maintaining maximum stability, resulting in smoother machine operation and lower power consumption. This advancement underscores Groz-Beckert’s commitment to sustainable production without compromising performance.

The company’s close collaboration with circular knitting machine builder Pailung has yielded two pioneering knitting systems: the Vo-Spec 94.41-30 G 0010 transfer needle and a new compound needle. The Vo-Spec needle, with a remarkable 0.30 mm thickness and a 0.15 mm transfer clip, is the finest of its kind on the market, enabling ultra-precise loop transfers for high-definition structures and delicate fabrics. Meanwhile, the new compound needle offers superior reliability and longevity, even at high machine speeds or with challenging yarn types.

For staple fibre applications, Groz-Beckert’s SAN SF needle and SNK SF sinker combination significantly reduce contamination, extending cleaning intervals and improving machine uptime. In flat knitting, the SAN TT and SAN FY needles demonstrate the company’s continued innovation in specialised applications. The SAN TT is optimised for tight loop formation in technical and medical textiles, while the SAN FY ensures flawless results with uneven effect yarns used in fashion and creative knitwear.

The legwear segment also benefits from Groz-Beckert’s advances, with its durable dur needles ensuring precision and longevity in fine hosiery production. Complementing these are newly engineered system parts, such as toe-closing components, designed to ensure perfect loop transfer and consistent fabric finish.

In warp knitting, Groz-Beckert continues to push technological limits with new guide needle developments for Piezo-Jacquard machines, enhancing stability and loop control.

By placing knitting at the core of its ITMA Asia presentation, Groz-Beckert reaffirms its leadership in precision tools that define modern textile manufacturing. Each innovation reflects the company’s deep expertise and ongoing commitment to supporting customers with solutions that combine performance, sustainability, and design freedom.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more