New Dates for ITMA ASIA + CITME 2022

Discover the power of seamless knit innovation in Singapore - from 3D digital design to a gauge 40 swimwear revolution.

23rd October 2025

Knitting Industry

|

Brescia, Italy

Santoni S.p.A., world leader in seamless circular knitting technology, is set to present two groundbreaking innovations that mark a new era for the textile and fashion industries. At ITMA Singapore, Santoni invites visitors to experience the launch of its SWS-3D revolutionary software for digital knitwear design, alongside the exclusive debut of its Seamless Gauge 40 Swimwear Capsule Collection - a world-first in sustainable and fully automated swimwear production.

SWS-3D: The future of digital knitwear starts here

The patented SWS-3D is the first software in the world that allows designers to program Santoni’s seamless circular knitting machines directly from a three-dimensional digital twin of the garment - no machine-specific technical skills required, Santoni says.

Created for designers, developed with precision engineering, and built to revolutionise the workflow from sketch to final garment, SWS-3D represents a quantum leap in digital apparel development.

Design without limits, realism without compromise

Through ultra-realistic 3D simulation, SWS-3D allows users to preview the finished garment in real time - including shape, proportions, and fit - reducing sampling time and material waste while accelerating the creative process. It's a patented, future-ready solution designed for the next generation of fashion manufacturing.

“With SWS-3D, we’re eliminating technical barriers for designers while delivering the high-performance precision that sets Santoni apart,” says Mrs Adele Lonati, Sales Director at Santoni. “It’s a bold step forward that brings fashion creativity and manufacturing technology into perfect sync.”

Seamless integration, infinite possibilities

SWS-3D seamlessly integrates with industry-standard tools such as CLO and Adobe Illustrator, enabling collaborative work between designers, technicians, and production teams.

Patented gauge 40 seamless swimwear - a breakthrough for the industry

At ITMA ASIA + CITME in Singapore, Santoni will also unveil a revolutionary leap in circular knitting: the first-ever application of gauge 40 seamless technology for the swimwear industry.

Santoni’s SM8-TOP2V machine now produces complete, high-performance one-piece swimsuits in just 10 minutes, with zero material waste - a direct challenge to the century-old cut-and-sew model that dominates swimwear production.

Redefining manufacturing economics

This fully automated process eliminates cutting, sewing, and manual finishing, reducing labour costs by up to 70% and minimising production complexity. The precision of gauge 40 enables advanced body mapping, delivering targeted compression, support, and unmatched comfort — all in a single, seamless garment.

Sustainability at the core

Santoni’s seamless swimwear technology uses 100% of the input material, resulting in zero production waste. By consolidating multiple steps into one machine and eliminating inter-stage transport, it significantly reduces the environmental impact, offering brands a powerful solution in response to rising sustainability demands.

Made for agility and customisation

With low setup times and stitch-level control of yarns, the technology supports small-batch, on-demand production, enabling faster response to market trends while maintaining premium quality. Complex fabric constructions and technical yarns offer functionality like UV protection, chlorine resistance, and rapid drying, all achieved seamlessly.

New seamless machines on display in Singapore

In addition to software and swimwear innovations, three cutting-edge Santoni machines will be showcased at the exhibition:

- SM8-TR1S – a completely updated version with new structural components and electronics, designed for high-performance seamless production.

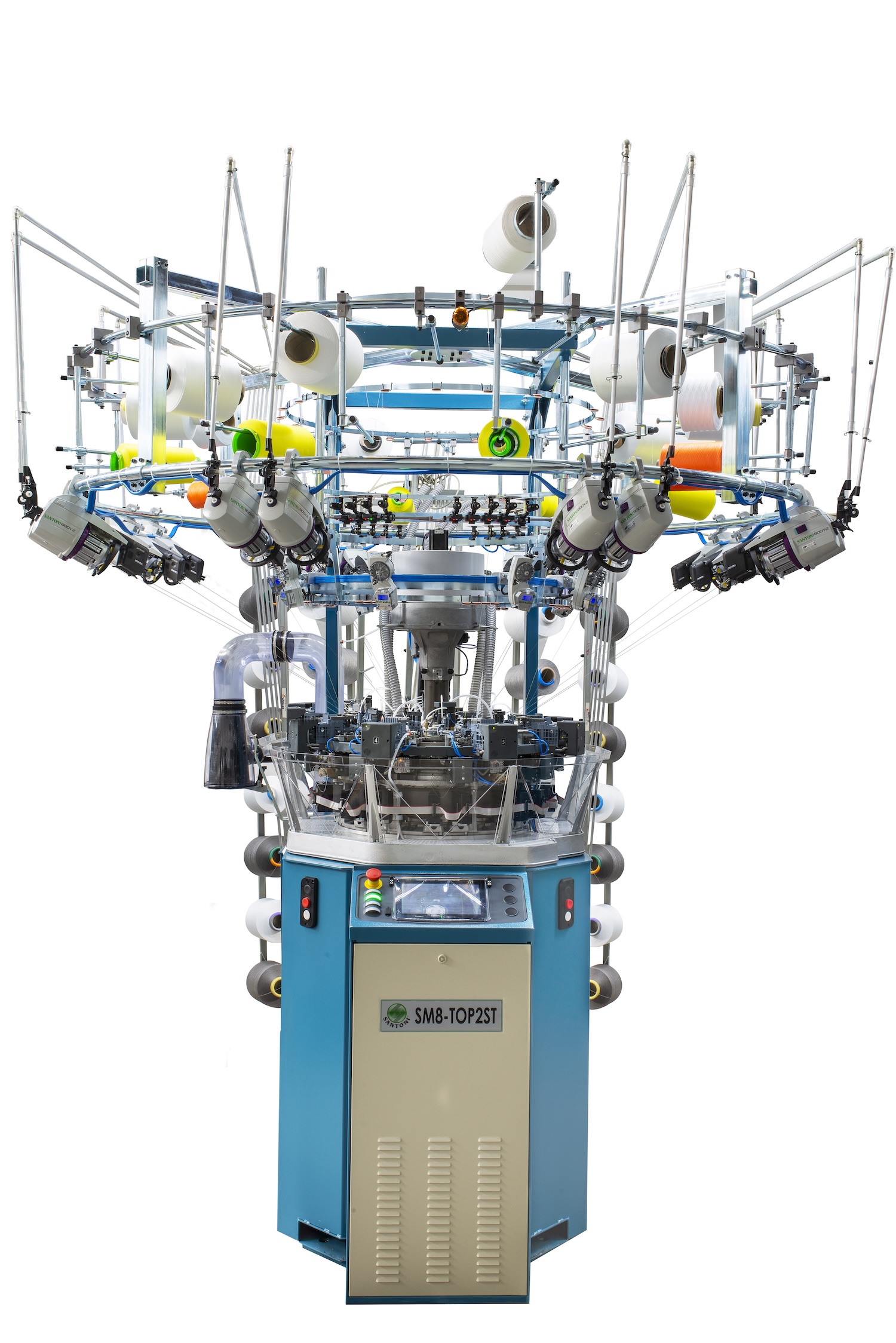

- SM8-TOP2ST – A revolutionary machine capable of producing innovative 3D structures with needle-by-needle selective terry, thanks to a mechatronic device protected by two patents developed by Santoni’s R&D.

This technology enables garments with strategically placed channels for breathability and thermoregulation, as well as 3D geometrical zones that deliver a massaging effect and exceptional softness. Unlike traditional 3D knitting, which relies on fabric wrinkling through needles in miss position, the SM8-TOP2ST allows full 3D shaping without compromising on production speed. Santoni has filed four patents to protect the textile patterns and 3D terry structures created by this machine.

- X-MACHINE – Shown in a new configuration, with 192 needles and in gauge 48 (needle thickness 0.6 mm), this machine is perfect to produce superfine intarsia products with cushioning areas in sculpted terry. The knitting head includes cams and a patented chain linking system, allowing preselected needles to engage with the stitch cam only when needed. Santoni has filed new machine patents to support the knitting of high-definition-coloured stitches.

Visit Santoni – Hall H5, Booth D203

Santoni invites all swimwear brands, knitwear manufacturers, designers, and textile industry professionals to visit its booth and experience the future of seamless garment production.

Visitors will explore:

- Live demonstrations of SWS-3D and seamless knitting machines in action

- The exclusive Capsule Collection made with Gauge 40 swimwear technology

- The latest generation of seamless machinery, ready to elevate your production capabilities

Visit Hall H5 – Booth D203 and discover how Santoni is shaping the future of sustainable, high-performance, and digitally-driven fashion manufacturing.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more