Lonati shoe upper machine debuts in China

Double-cylinder innovation boosts sock output by 61%.

4th August 2025

Knitting Industry

|

Amagasaki, Hyogo, Japan

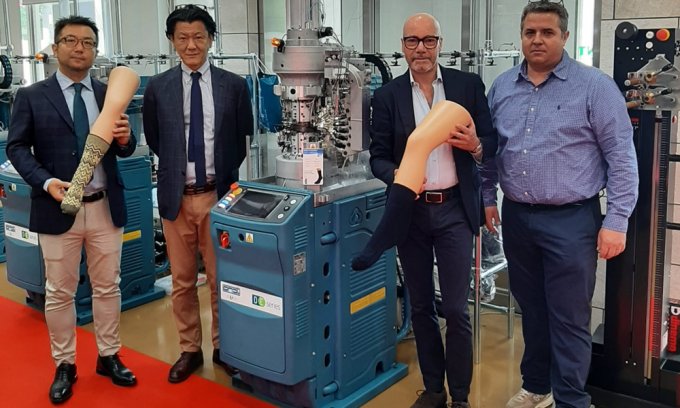

During a private show hosted by UNION in Amagasaki from 20–23 May, Lonati presented its latest innovation in sock knitting technology: the DC88 DE 2H2. The double-cylinder machine introduces a new benchmark in productivity and textile versatility for men’s, women’s, and children’s sock production.

Designed as a full two-feeds model, the DC88 DE 2H2 incorporates advanced technologies that enable simultaneous two-feed knitting, even during reciprocation—an industry-first for this machine type. The result is a dramatic increase in production speed without compromising quality.

The DC88 DE 2H2 includes a single HF magnetic needle selection system for managing ribs, links, and Jacquard patterns. It supports tuck stitch knitting on the lower cylinder across both feeds, enhancing fabric performance and structure. Precision is ensured via a brushless motor with variable reciprocation and HTD belts with automatic tensioners, extending system longevity.

A magnetic encoder embedded in the lower cylinder manages its positioning, ensuring stitch accuracy throughout the production cycle. Heel and toe phases benefit from four selection points that replace pickers and droppers, allowing greater design freedom in both single and double feed modes.

Energy efficiency is a key feature. The redesigned knitting head reduces compressed air use by 80% compared to traditional models. For example, the DC88 DE 2H2 consumes only 17 NL of compressed air per short-size sock (size 11), compared to 110 NL with a conventional one-feed machine.

In terms of output, the DC88 DE 2H2 achieves 39.56 socks per hour versus 24.49 with a one-feed counterpart - a 61.5% increase - enabled by Lonati’s Integral technology for reciprocated two-feed knitting.

All functions are electronically controlled with active self-protection, diagnostics, and stepper-motor-driven fabric width adjustments. The machine integrates seamlessly with ORION graphic programming software and is compatible with Nautilus and Arcadia systems for real-time production monitoring.

Offered in diameters of 3”1/2, 3”3/4, and 4”, with gauges from 9 to 22, the DC88 DE 2H2 underscores Lonati’s commitment to next-generation sock production.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more