Stäubli to show toe-closing device in Shanghai

Mauro Barbieri, Knitting Product Manager at Stäubli discusses the company's D4S automatic toe-linking solution for sock knitting machines.

26th October 2018

Knitting Industry

|

Shanghai

The Swiss company Stäubli, is highly respected in the field of textile engineering and a name synonymous with shedding and jacquard mechanisms for weaving - but it is also a major player in the global socks manufacturing industry via its Stäubli Deimo brand knitting solutions for process automation.

Stäubli knitting solutions optimize automated production in sock knitting mills worldwide. The company’s 2900SL electronic control system, for example, enables hosiery knitting mills to rapidly respond to the changes of market demands in production, whilst at the same time improving quality and production efficiency.

Additionally, its D4S device, automatically closes sock toes directly on the knitting machine, so that no operator intervention is required. Combined with programming systems for production monitoring (DData) and graphics (DStyler), the entire socks production process can be facilitated and optimized by Stäubli Deimo knitting solutions.

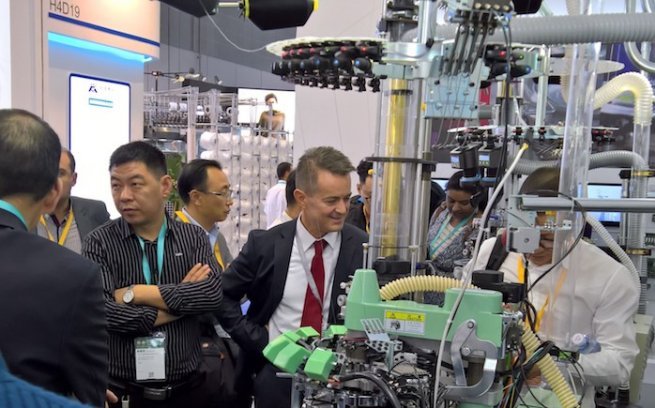

Knitting Industry met with Mr. Mauro Barbieri, Knitting Product Manager at Stäubli, on the company’s booth at last week’s ITMA Asia +CITME in Shanghai, to discuss the D4S automatic toe-linking solution for sock knitting machines and the impact it is having in the market.

Revolutionary idea to world class product

The D4S is based on a completely revolutionary idea for automatically linking socks directly on the knitting machine and is available for sock knitting machines with a diameter of 3½” to 4½” and from 8 gauge to 19 gauge. “Once the D4S is installed on a knitting machine, gauge changing is both fast and easy,” Mauro Barbieri says. “The D4S represents a quantum leap for knitters who want to excel in the hosiery market”.

Key benefits

Mr Barbieri sums up the key benefits of the D4S as: significantly higher productivity in sock manufacturing; rapid payback thanks to an excellent price/performance ratio; and easy adaptability to a range of diameters and gauges.

Prior to launching the D4S at ITMA 2015 in Milan, Stäubli worked intensively to develop a world class automation solution for toe closing on circular sock knitting machines. After acquiring several concept patents, the company developed and improved it extensively, and launched a complete Stäubli developed product, designed and manufactured in Italy, at the world’s leading textile machinery exhibition. Stäubli manufactures the machine controller and all of the mechanical parts for the D4S device.

User friendly with high quality

“We have designed our D4S device to be simple to use – to be user friendly via our mechanical solution and our controller. We have also minimised the number of mechanical parts within the device to enable easy use and simple maintenance,” Mr Barbieri says.

“Our system is a fully electronic synchronised one, and we offer very low machine downtimes, with minimum stoppages to remove the sock from the machine.”

“This all leads to a good return on investment for the sock producer, but we also offer significant quality advantages. Our toe linking device yields very good stitch quality – true 1 by 1 linking with a very tight stitch and excellent appearance on the toe of the sock – and on any kind of socks,” he adds.

All about automatic toe closing

The global socks machine market is on course to move completely to automatic toe closing machines within the next few years – leading Italian machine builder Lonati claims that 90% of the machines it manufactures are now equipped with automatic toe closing devices.

Stäubli can already count a number of leading sock machines builders amongst its D4S clients, including Taiwan’s Da Kong and Tai Ho Shing, as well as Italy’s Rumi. Both Da Kong and Tai Ho Shing exhibited D4S equipped machines at ITMA Asia + CITME, and all three exhibited D4S fitted models at this summer’s FIMAST in Brescia.

Mauro Barbieri estimates that China has several significant machine builders - so, all in all, the opportunity is good.

“China no longer wants to make open-toe socks, because labour costs for toe linking are rising and there is a shortage of labour,” Mauro Barbieri explains.

“We are very proud to be able to offer a viable alternative for socks manufacturers, with Stäubli quality, innovation and performance,” Mauro Barbieri concludes.

About Stäubli

Stäubli is an international group that currently operates in 29 countries, with agents in 50 countries on four continents. Its global workforce of 5000 shares a commitment to partnering with customers in many industries to provide comprehensive solutions with long-term support. Originally founded in 1892 as a small workshop in Horgen/Zurich, today Stäubli is an international group headquartered in Pfäffikon, Switzerland.

Further information

Contact: Mauro Barbieri

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more