New subsidiary and new managing director

Company to present new solutions at ITMA ASIA + CITME 2025.

19th September 2025

Knitting Industry

|

Obertshausen, Germany

Karl Mayer will present a wide range of innovations under the motto We Warp. We Knit. We Care. at ITMA ASIA + CITME 2025 in Singapore. The company’s 360 m² booth will highlight new technologies in warp knitting and warp preparation, designed to boost customer productivity, efficiency and competitiveness.

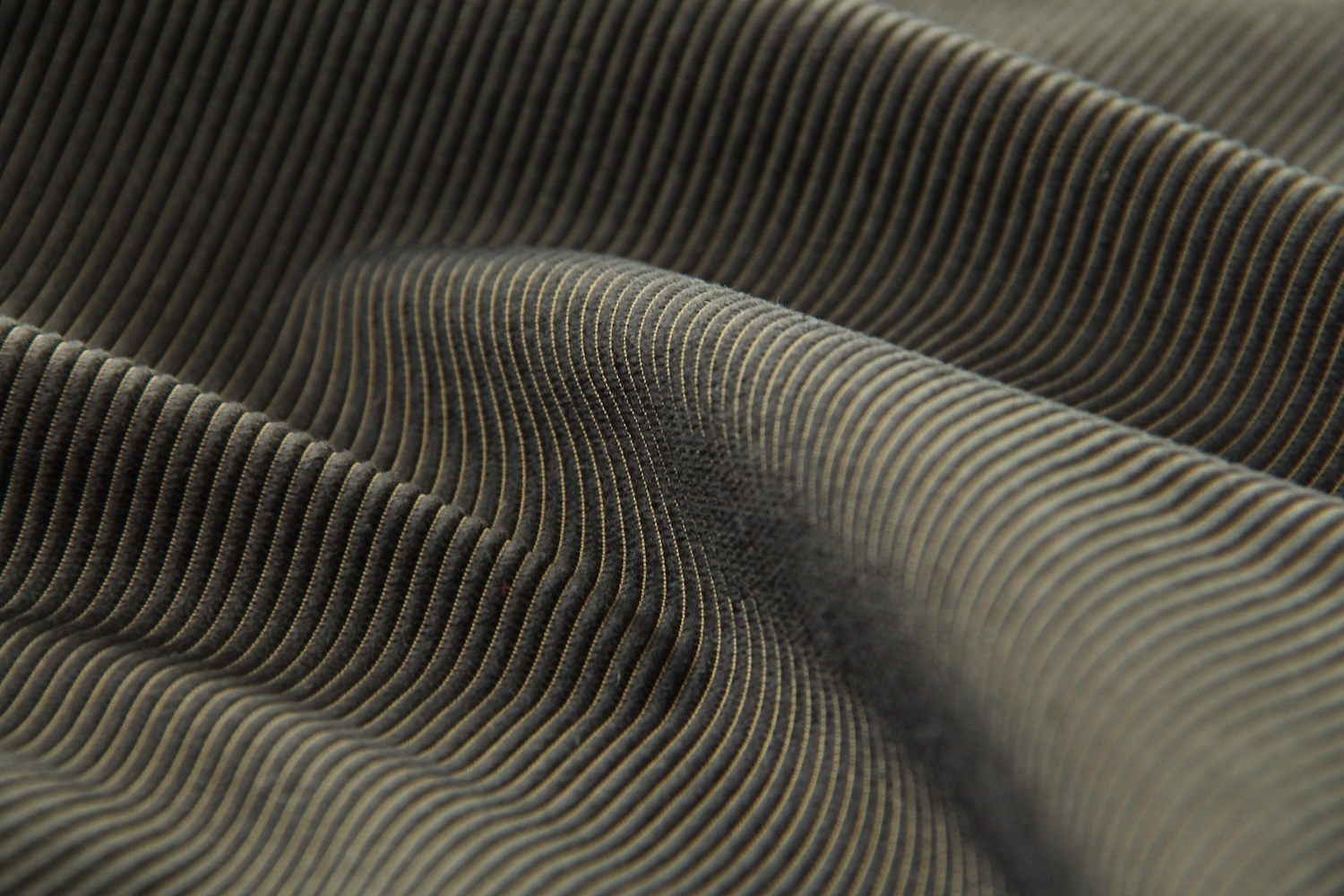

Visitors to the We Knit Fashion showcase can expect a diverse textile presentation featuring cosy faux fur, classic and innovative corduroy, Rascheltronic fabrics, seersucker designs and elastic materials for casual business wear, activewear, swimwear and underwear.

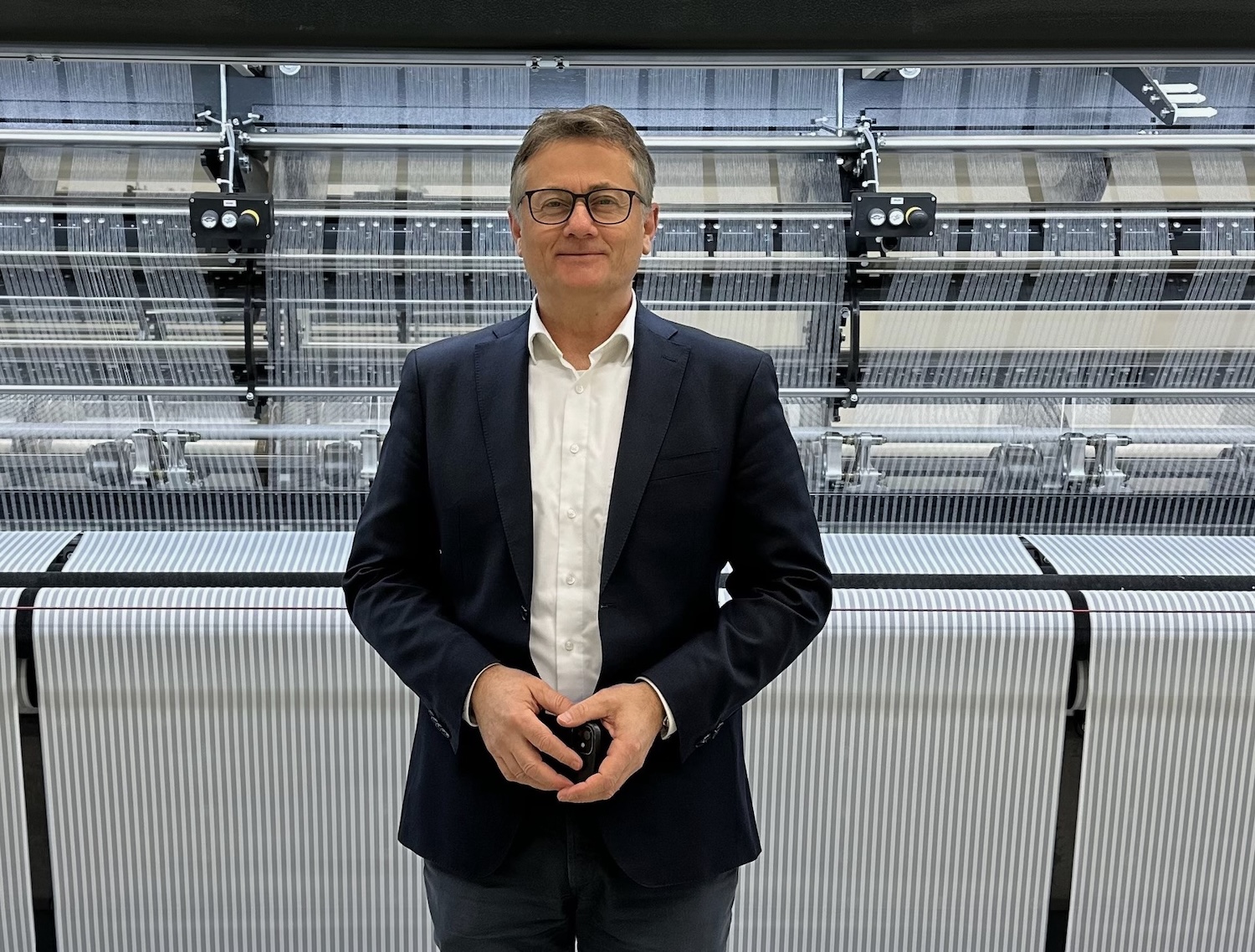

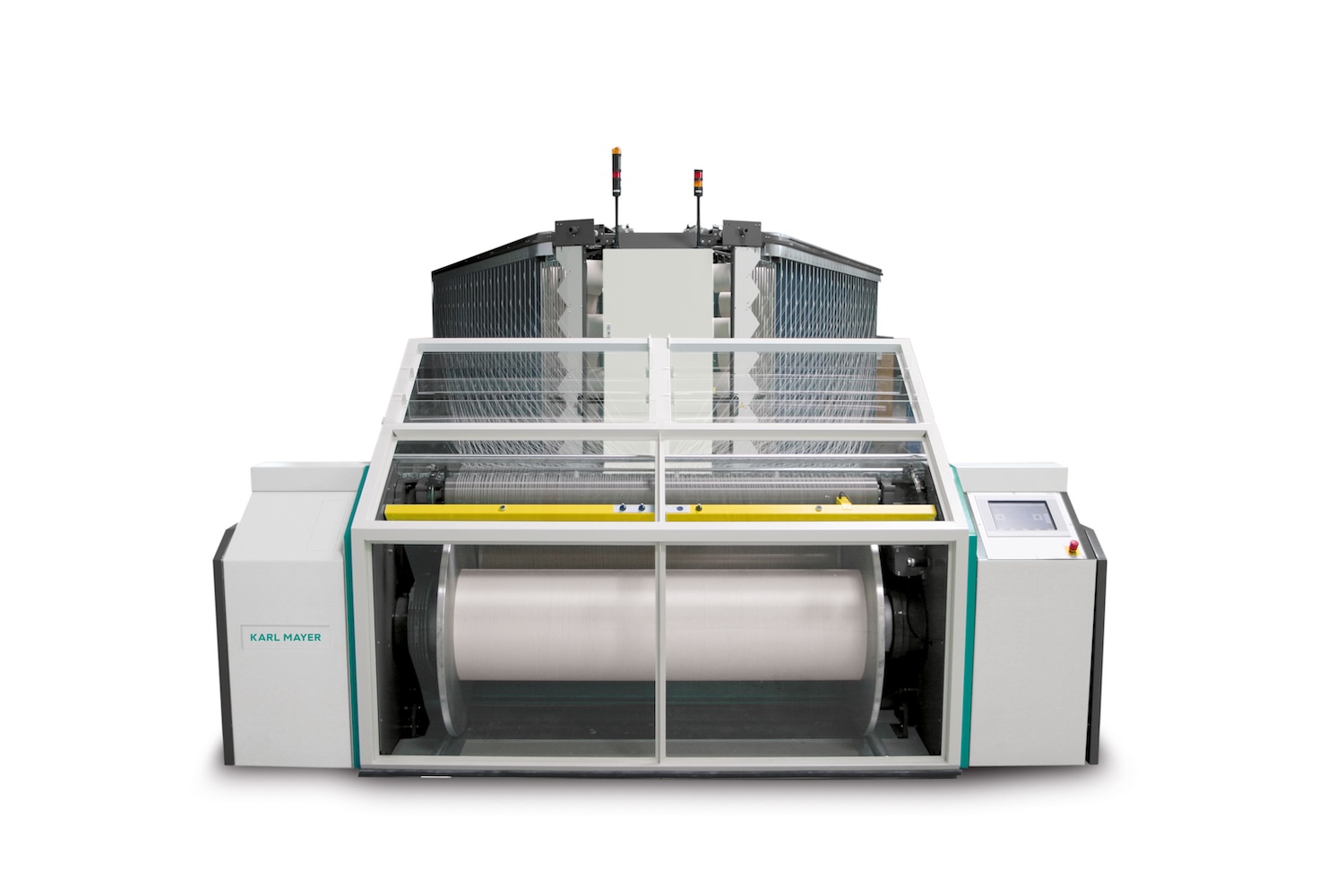

A highlight will be the premiere of two tricot machines. A new two-bar model for elastic fabrics is designed to deliver maximum value with improved margins, while a new four-bar machine targets the fashion and apparel segment with regional market suitability.

“We are proud to present two state-of-the-art and high-performance tricot machines developed to meet the fundamental requirements of the textile industry,” said Axel Wintermeyer, President of the Warp Knitting Business Unit.

Technical textiles will also feature strongly. Hollow fibre mats, knitted for use in artificial lungs, demonstrate the potential of textiles in medical technology. Non-crimp fabrics and weft insertion warp knits provide sustainable solutions in construction, offering efficiency and reduced environmental impact.

“Our machines open up interesting new avenues in specific fields or provide more advantageous alternatives,” said Hagen Lotzmann, President of the Technical Textiles Business Unit.

In weaving preparation, Karl Mayer will present energy- and cost-efficient technologies, including the Cascade steam and condensation system for Prosize and the Warpdirect warping machine. These solutions aim to reduce yarn waste, improve quality and enhance efficiency. “We have prepared a versatile presentation focused on solutions that support customer success in today’s challenging conditions,” added Enzo Paoli, President of the Warp Preparation Business Unit.

The company will also highlight its Care Solutions services, including training, consulting and technical support, alongside new developments for its Customer Portal and Webshop.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more