New subsidiary and new managing director

Company celebrates 35 years of electronic pattern drive.

3rd December 2025

Knitting Industry

|

Obertshausen, Germany

Karl Mayer is marking the 35th anniversary of its EL pattern drive, a technology that transformed warp knitting by replacing mechanical pattern control with fast, precise electronic systems. The first warp knitting machine equipped with electronic guide bar control, the KS 4 EL, was delivered on 30 November 1990, marking the beginning of a new era for patterning freedom and machine performance.

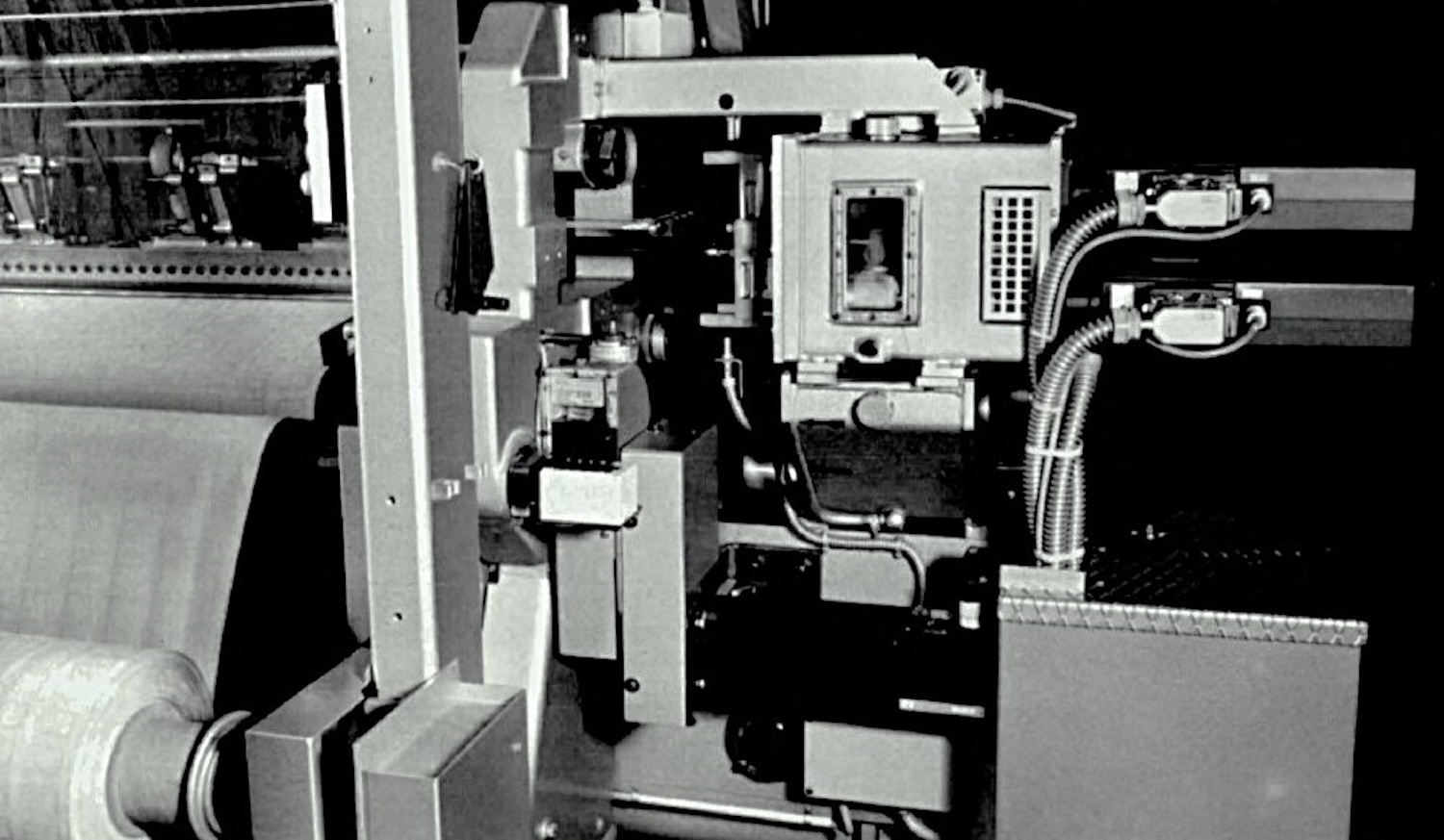

The shift towards digital patterning began a decade earlier. In 1980, the SU gearbox used on the MRS42SU Multibar Raschel machine introduced cassette-based patterning in place of mechanical chains. Magneto-mechanically controlled via actuators and a microcomputer, the SU drive offered unlimited repeat lengths, faster production speeds, shorter set-up times and rapid pattern changes without exchanging chains. The 1985 development of an SU drive with integrated overlap device allowed the same concept to be extended to tricot machines, paving the way for subsequent electronic solutions.

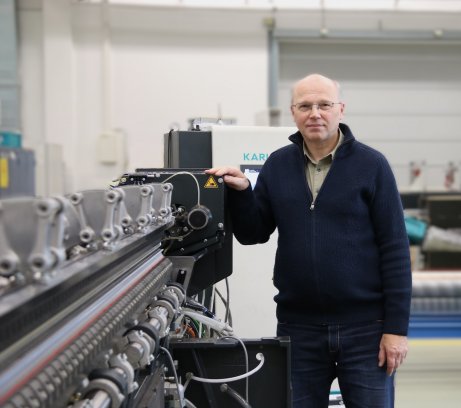

To surpass the mechanical limitations of the SU system, Karl Mayer began developing a fully motorised guide bar drive. Senior Expert Technology Development Georg Kraus recalls the challenge of entering “completely new territory” by attempting to move the guide bars using electric motors rather than mechanics. Early test rigs using asynchronous motors and ball screws demonstrated accuracy, speed and reliability, leading to the first EL-controlled machines.

The KS 4 EL delivered remarkable improvements: up to 37% higher speed than its SU-equipped predecessor, unrestricted patterning via data transfer, and reduced maintenance and space requirements. This success enabled the rapid expansion of EL technology to other machine types, including Nippon Mayer double raschel models, technical textile machines and later lace raschel systems. By 2002, the first Multibar Raschel machine with fully electronic guide bar control, the TL 66, was launched. Its compact mechanics made room for additional guide bars and greater shogging distances, expanding creative potential beyond what was possible with SU equipment.

The EL system has since evolved into a platform supporting additional warp knitting functions. Its principles underpin Advanced Feeding Control (AFC), which optimises yarn feeding for complex patterns with variable yarn consumption. Machines equipped with AFC include the fastest three-bar tricot model with electronic guide bar control, unveiled at ITMA 2023, which produced pleated fabric at 2,900 rpm. EL technology also forms the basis of the Vario Weft laying system for the Wefttronic II G, introduced at the same event. The system enables weft patterning without mechanical threading adjustments, removes repeat limitations and reduces edge waste.

Looking ahead, technology pioneer Georg Kraus believes the potential of EL drive technology is far from fully realised. He anticipates that it will eventually replace the N pattern drive entirely and foresees numerous opportunities for further electronic innovation across warp knitting machinery.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more