Karl Mayer to hold Obertshausen show during Heimtextil

Warp Knitting/Crochet

Karl Mayer revamps technology for producing sacks

As the most important element, the double-bar raschel machine has been equipped with an EL pattern drive.

22nd November 2017

Knitting Industry

|

Obertshausen

Karl Mayer has revamped its machine technology for producing packaging sacks. As the most important element, the double-bar raschel machine has been equipped with an EL pattern drive, which enables variable sack lengths and lappings to be worked.

An FTL unit is located at the beginning of the processing chain for producing sacks. This element in the production line has a cutting bar for cutting a double-layered, primary polyolefin film into tape yams and drawing them in a heating zone to produce monoaxial flat film yarns. These yarns are delivered to the Double-bar raschel machine, in depending of the demand.

The needs-based delivery of the tape yarns is a decisive factor for online process control, just as is the exact harmonisation of the machine technology as a whole. “With this non-stop sequence, everything must function perfectly, and all the components have to be in perfect harmony, rather like an orchestra,” said Rainer Baier, a product developer, at the machine presentation.

Tried-and-tested basic design

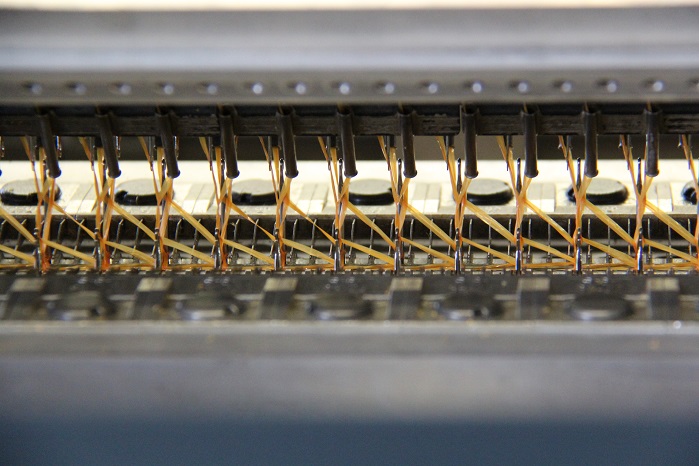

An RDS 11 EL is used to knit the tape yarns to produce complete sacks. The machine is supplied with a width of 193", a gauge of E 6, a threading arrangement of 1 in, 2 out, and a set of warp knitting elements comprising two compound needle bars, two knock-over comb bars, four ground guide bars and seven pattern bars.

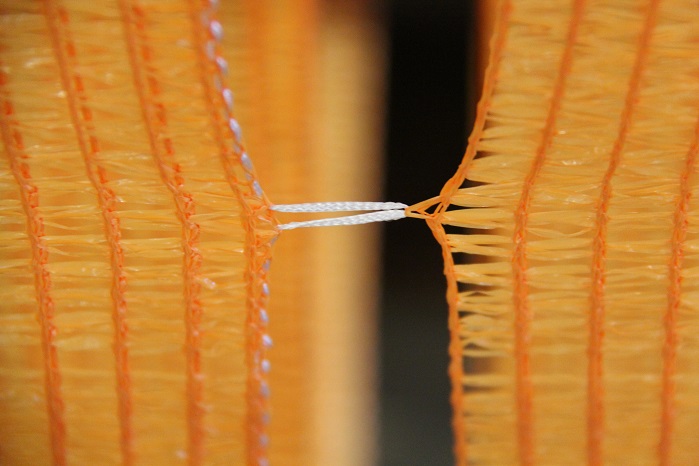

With this configuration, the RDS 11 EL works a combination of a pillar stitch and weft lapping. Two separate webs are produced, one by ground guide bars, GB 4 and GB 5, on the rear needle bar and one by GB 7 and GB 8 on the front needle bar. The two mesh webs are joined together on one side in the working direction by pattern bar, PB 6. The seam forms the base of the packaging sack. The opposite side is open to enable the sack to be filled. The openings in the horizontal direction are also closed, by changing the lapping, to produce the side seams of the sack.

Customised sacks

The RDS 11 EL offers a number of options for the efficient production of ready-to-use sacks, including the incorporation of sealing tapes, flaps for automatic filling, an adhesive strip for the subsequent application of labels, and contact yarns for subsequent process control.

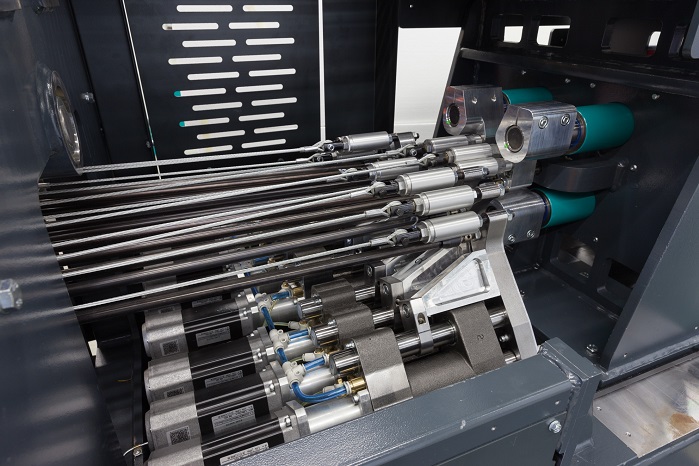

Above all, the dimensions of the product can be varied. For example, the opening widths of the nets can be varied via the stitch density, i.e. via the take-down, and by the lapping. The depth of the sack can also be changed via the threading arrangement of the guide bars as a function of the number of webs produced in parallel. The width of the sacks can also be varied as required. The width is determined by the repeat length, which can be freely selected and changed easily. The reason for this is that, unlike its predecessor, the RSD 11 EL has been equipped with a new feature, the EL pattern drive, the company reports.

This electronic system replaces the old, mechanical NNC type. It does not use pattern chains or discs and is said to enable the pattern to be changed easily. The repeat lengths can also be changed easily to adjust the size of the sacks. The RDS 11 EL has also been newly equipped with the Kamcos system.

Stacks or rolls

Two systems are available for taking-up the warp-knitted sacks, i.e. the 26/6 batching unit and the STMR sack separating machine.

The batching unit produces rolls from the sack webs which, as “automatic sacks”, are fed fully automatically to the filling machine. Alternatively, the STMR process produces piles of individual sacks that are ready to be filled.

In this case, the textile webs run via a roller feed unit to a thermal cutting unit on a swivel-mounted frame. Once the predetermined width of the sack has been reached, it is cut by a horizontal stroke of the cutting unit along the side seams. The RDS 11 EL incorporates a marking thread, so that sensor technology can be used to detect the cutting points. The separated sacks are then stacked using the swivel-mounted frame until the set number has been reached. They are then removed via a conveyor belt.

Ideally suited to the market

“Thanks to online process control and the high efficiency of the RDS 11 EL, Karl Mayer’s line for producing sacks operates at an extremely high production rate,” the manufacturer explains. “At a speed of 900 courses/min, an average of about 900 sacks per hour can be produced – depending on the dimensions selected and the stitch density.”

The first complete line with FTL unit and batching unit for automatic sacks left Karl Mayer’s headquarters in Obertshausen in September 2016.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more