Stoll presents latest innovations in Bangladesh

New package provides sophisticated solutions for even more customer benefits.

6th July 2023

Knitting Industry

|

Reutlingen, Germany

ITMA 2023 was an immensely successful platform for the flat knitting machine manufacturer Stoll to present its latest new developments, the company reports. The business unit of the Karl Mayer Group is following up the world’s most important trade show for textile machinery with the launch of a further innovation package.

With the solutions contained in the new package, Stoll will be offering its customers additional added value when using their flat knitting machines, in line with the concept of bundling innovations.

Centralised lubrication

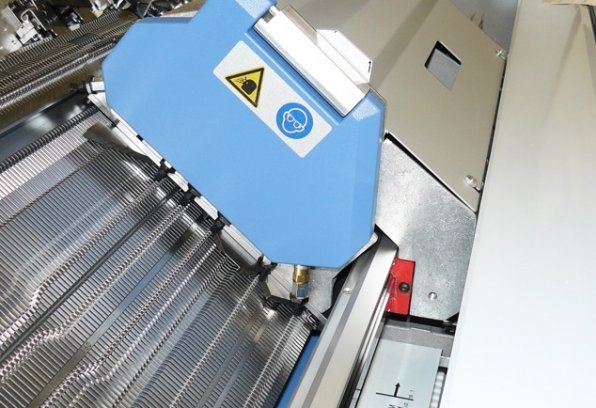

The new features include an optimised central lubrication system that reduces both maintenance effort and oil consumption, which will be standard from July 2023 for all models of the CMS and ADF series produced in Reutlingen.

Compared to the previous optional variant, the new central lubrication system ensures more efficient and comprehensive lubrication. All needle bed elements, from the holding-down jack to the coupling part and intermediate slider to the selection jack, are now supplied with oil, and the machine itself recognises whether lubrication is required.

Independently of this, the lubrication intensity and oil distribution can be adapted to the individual machine conditions by setting various parameters, if required. To ensure that the required amount of lubricant is reliably supplied, a message is sent if the level is too low.

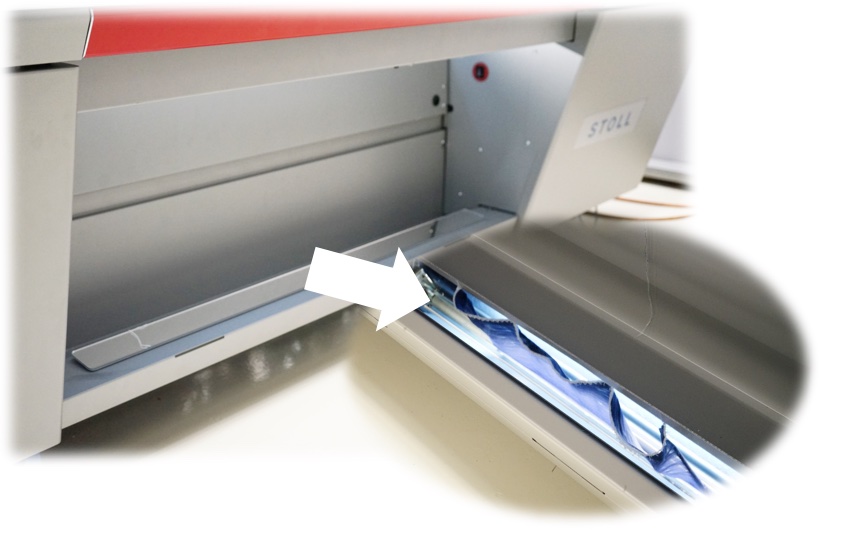

In addition, a new oil drain container as standard equipment for all CMS and ADF models catches used oil from the needle bed under the machine. This prevents soiling of floors or knitted fabrics. The emptying of the container can be efficiently managed by an adjustable reminder function. The neat and at the same time sustainable solution does not require cleaning agents or hoovers and offers the possibility to reuse the oil after cleaning through special filters, if necessary.

Belt take-down

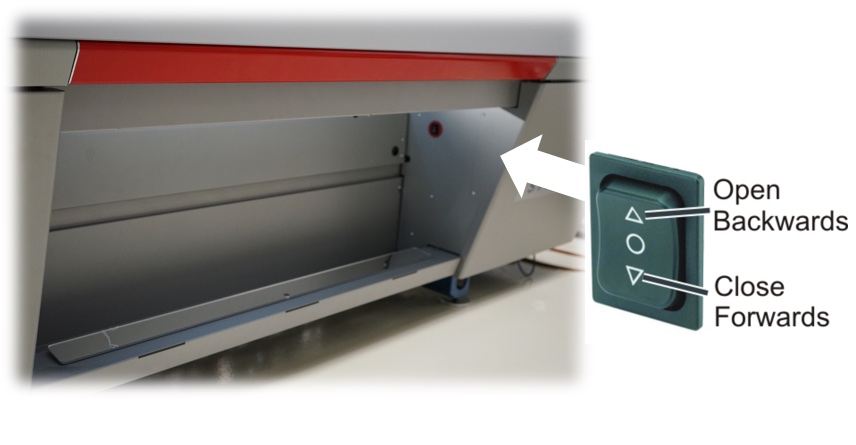

Users of CMS and ADF belt take-down machines can benefit from optimisation around the belt take-down.

Thanks to the new Stoll innovation package, this can be turned forwards and backwards by means of a switch as standard in order to easily eliminate fabric wraps and thus reduce maintenance times. In addition, a mirror, which is also fitted as standard, ensures a simple visual check of the belt take-down.

New cams

Another solution in the Stoll innovation package from July 2023 includes new cams that enable split-stitch implementation without cam box modification. This reduces manual effort and thus conversion times and costs. The feature is standard on all fine gauges ADF and CMS machines.

Inlay carrier

For the W machines from Stoll, there is now a further inlay yarn carrier, the Qt, in addition to the previous Qw yarn carrier. The extension means that the number of inlay yarn carriers used in a system can be increased from the previous one to three. No additional system is required for the weft yarn, and the process steps weft yarn insertion and knitting take place in the same system.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more