World changing textile innovations

June 2009, Frankfurt - Italian yarn feeder manufacturer LGL Electronics showed its latest developments at the recent Techtextil exhibition, including its new Spin tension controlling device and Compact yarn feeder with reduced dimensions and weight. Compact Speaking at Techtextil, LGL’s Enrico Guerinoni told KnittingIndustry.com, “LGL has designed another new feeder called Compact for large diameter circular knitting machines, which combines reduced dimensions, user friendliness and oth

29th June 2009

Knitting Industry

|

June 2009, Frankfurt

- Italian yarn feeder manufacturer LGL Electronics showed its latest

developments at the recent Techtextil exhibition, including its new Spin

tension controlling device and Compact yarn feeder with reduced dimensions and

weight.

June 2009, Frankfurt

- Italian yarn feeder manufacturer LGL Electronics showed its latest

developments at the recent Techtextil exhibition, including its new Spin

tension controlling device and Compact yarn feeder with reduced dimensions and

weight.

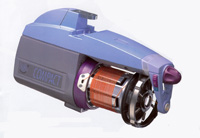

Compact

Speaking at Techtextil, LGL’s Enrico Guerinoni told KnittingIndustry.com, “LGL has designed another new feeder called Compact for large diameter circular knitting machines, which combines reduced dimensions, user friendliness and other important recent technical innovations.”

The company says that Compact is its response to the challenging requirements of today’s world markets. Compact replaces an electro-mechanical system with an electronic system to reduce variation and dimensions.

As the name suggests, Compact has very compact dimensions and reduced weight which is important on machines with high numbers of feeders. Energy consumption is minimized via a brushless motor and Compact can be fitted with the same accessories as the company’s Primo, Attivo or Vector feeders.

Compact has a yarn consumption function which offers real time electronic measuring of the yarn consumption to all feeds (up to 256 max.) at the same time. Z and/ or S rotation can be selected as needed. Guerinoni explains that Compact’s on-off switch is easily accessible and the signalling lamp is visible from anywhere around the knitting machine. It can also be installed in any desired position, whether vertical, inclined or horizontal.

Compact characteristics

Yarn counts: from 5 to 600 denier

Speed: up to 700 m/min

Fixed separation of windings: 0.9mm

Dimensions: 240 x 70 x 130mm

Weight: 1.4 Kg

Spin

LGL Electronics has also extended its range of feeders

dedicated to all kind of knitting and hosiery machines with a new tension

controlling device called Spin. Spin, which is used with covered and uncovered

elastane yarns has been on test with LGL customers and is now on sale. LGL says

that it answers all of their customers’ needs in the area of yarn measurement.

LGL Electronics has also extended its range of feeders

dedicated to all kind of knitting and hosiery machines with a new tension

controlling device called Spin. Spin, which is used with covered and uncovered

elastane yarns has been on test with LGL customers and is now on sale. LGL says

that it answers all of their customers’ needs in the area of yarn measurement.

The precision of a new ceramic tension sensor, electronic drive and the use of the best materials such as aluminium and the fully dedicated development of mechanics and electronics give LGL the chance to open up new horizons in the field of yarn tension control at any speed, the company says.

According to LGL, Spin reacts quickly to speed changes without producing tension peaks and has a maximum torque available over a large speed range (in particular at low speeds). LGL says, it also offers low power consumption via a brushless motor and is easy to install. Communication is via Serial and CAN BUS and both flat and single cables can be used. Spin competes with BTSR’s Ultra and Memminger-Iro’s EFS800.

Spin characteristics

Range of yarns: bare and covered elastomeric yarns

Spool body diameter: 43mm

Tension range: from 0.5g to 50g

Maximum speed: electronically limited to 1700m/min (32VDC) or 1100 m/min (24VDC)

Dimensions: 140 x 60 x 50mm

Weight: 350g

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more