Mayer & Cie ships 77,777th circular knitting machine

Relanit, one of Mayer & Cie.’s (MCT) most important and most successful machine types, is celebrating its 30th anniversary this week.

11th October 2017

Knitting Industry

|

Albstadt

Relanit, one of Mayer & Cie.’s (MCT) most important and most successful machine types, is celebrating its 30th anniversary this week. Launched at ITMA in 1987, it uses relative technology, the circular knitting machine manufacturer’s proprietary development.

In its current version, the Relanit 3.2 HS is one of the most productive single jersey machines on the market, the company reports. At the same time, its energy consumption is 30% below that of a conventional knitting machine. Relanit is also part of Mayer & Cie.’s latest innovation, spinitsystems technology.

Thanks to relative technology, a fragile fibre bundle can become a fluffy single jersey fabric. “Relative technology is still the shape of things to come, 30 years after the start of series production,” said Marcus Mayer, Managing Director, Mayer & Cie., in charge of technical development. “It exemplifies what we stand for, for our values and our aspiration to always be one step ahead.”

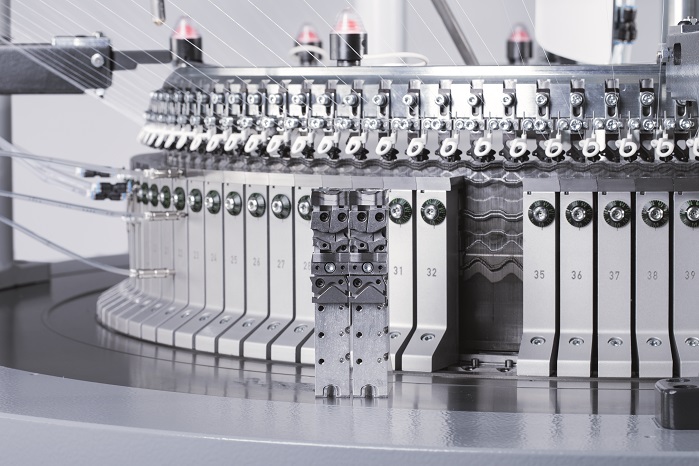

Conventional knitting machines usually work with horizontal sinkers. That means the needle moves up and down while the sinker works horizontally. With relative technology, the sinker too moves up and down, shifting towards the needle. In this movement lies relative technology’s biggest advantage: In comparison to conventional technology, the yarn only has to travel half the number of deflection points to form a stitch. Each deflection means less stress on the yarn.

That is why Relanit can process difficult yarn or inferior qualities without a hitch. Not only to form a fabric of a certain quality but also without making amends in terms of production speed or machine downtimes. Because yarn is the key cost factor in knitting, Relanit can help the knitter to save a lot of money, the manufacturer explains.

“When we unveiled Relanit at the Paris ITMA 30 years ago, it was unmatched in production, speed, yarn care and energy efficiency,” commented Marcus Mayer. “And it still is. We are not aware of any company that has succeeded in replicating the technology. As our patent expired years ago, that would be possible. And nobody has developed a better technology that combines all these benefits either, by the way.”

While relative technology in itself has remained unchanged, it has grown to keep pace with technological development. The line’s current flagship is the Relanit 3.2 HS. It is one of the most productive single jersey machines, both for open width as well as tubular. At 50 rpm it works with elastomeric yarns just as well as with cotton, the machine’s traditional speciality. Furthermore, the Relanit 3.2 HS uses up to a third less energy than a conventional circular knitting machine, the manufacturer reports.

In addition to the Relanit 3.2 HS, the current Mayer & Cie. portfolio comprises a further eight Relanit machines, with striping machines, electronic and mechanical types among them. Every year, around 300 Relanit machines find their way to clients around the globe. The specialists in cotton yarn are most popular in Turkey, followed by Brazil and China. Overall, Mayer & Cie. has sold 10,000 units, delivered to about 90 countries worldwide.

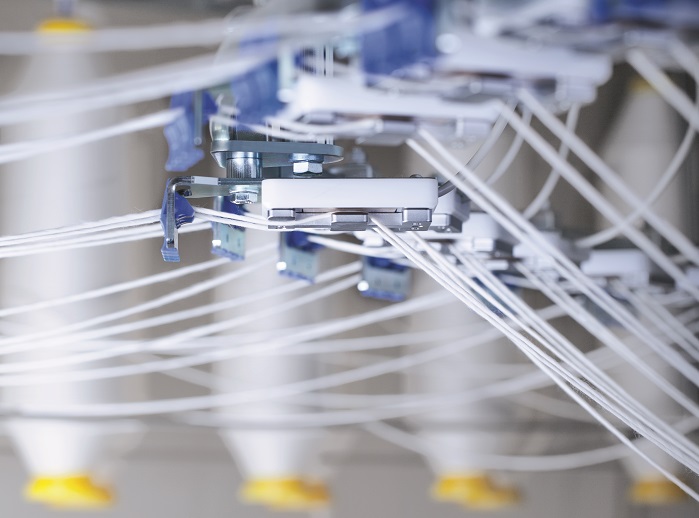

spinitsystems is the company’s latest innovation and it would not be possible without relative technology. The spinning and knitting machine Spinit 3.0 E combines spinning, cleaning and knitting. The raw material it works with is a not a regular cotton yarn but a roving, which easily dissolves when rubbing or tearing it.

The fibre bundle travels a much shorter distance and is subject to less tension than would be the case with conventional knitting technology. In short, it is thanks to relative technology that a fragile roving can be transformed into fluffy single jersey on Spinit 3.0 E. “That makes Relanit not only a technology we are very proud of, but also an obligation for the future,” concluded Mr Mayer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more