Satisfactory ITME for Mayer & Cie.

Depending on the web feed, the Spinit 3.0 E’s Fancy module can cover a bandwidth of between 80 and 200 grams per square metre.

4th November 2016

Knitting Industry

|

Albstadt/Mumbai

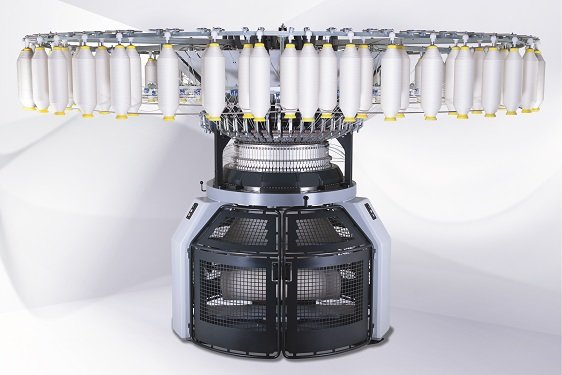

Leading international circular knitting machine manufacturer Mayer & Cie. will be showcasing its Spinit 3.0 E spinning and knitting machine at the upcoming ITME International Textile Machinery Exhibition that will be held in Mumbai, India, from 3 to 8 December 2016.

The Spinit performs three previously separate operations, delivering benefits in terms of production time, energy requirement and CO2 footprint. These advantages are complemented by the option of producing new patterns and at the Indian trade fair the company will present its ready-for-sale Fancy module, an optional patterning attachment for the Spinit 3.0 E.

Mayer & Cie. has chosen to present the ready-for-sale Fancy module at the ITME in India for a reason. “As one of the world’s largest textiles markets, India is one of our bridgehead markets for launching the Spinit 3.0 E, of which we are now in pilot production,” said Michael A. Tuschak. “Furthermore, India has a very high level of expertise in ring spinning, so we need to convince a demanding audience.”

Free alternation of opaque and transparent pattern areas is the speciality of the Spinit 3.0 E with a Fancy module attached, the company reports. The patterns differ in two respects from those that a jacquard machine can produce. One is in their look and appeal. Spinit Fancy Jersey patterns are characterised by their soft transitions. The other is the different production process. While a jacquard machine generates the patterns required by means of single needle selection, electronically controlled drafting systems are responsible for the pattern on a Spinit 3.0. They are designed to ensure an appropriate yarn gauge variation during the production process, thereby generating short and individual transitions.

Depending on the web feed, the Spinit 3.0 E’s Fancy module can cover a bandwidth of between 80 and 200 grams per square metre. Patterns are easily programmed using Mayer & Cie.’s design software MDS1. They can be uploaded using Wi-Fi or a USB stick.

“With our Fancy module, customers can give their fancy full scope,” commented Michael A. Tuschak, in charge of spinitsystems marketing and sales at Mayer & Cie. “We can produce patterns previously impossible, patterns that can be only produced with this technology.”

“We feel that in the Fancy module we can offer our customers an additional distinguishing feature,” said Michael A. Tuschak. “It can be switched off by pressing a button – and switched on again just as fast on demand.”

With or without the optional patterning attachment, the benefits of spinitsystems technology are extensive, according to the manufacturer. Because the machine combines three previously separate operations – spinning, cleaning and knitting – and rewinding is no longer required, the production process takes much less time and production costs are reduced accordingly.

And as the Spinit 3.0 E reduces the plant and machinery required to a single machine, the same applies to the capital investment cost. Energy requirement and carbon dioxide emissions are also said to be significantly lower than those of conventional machines.

Michael Tuschak of Mayer & Cie. on the Fancy module for Spinit 3.0

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more