October showcase for Autotex at FIMAST

New Sandonini SW6 machine offers high efficiency and automation.

17th June 2025

Knitting Industry

|

Italy

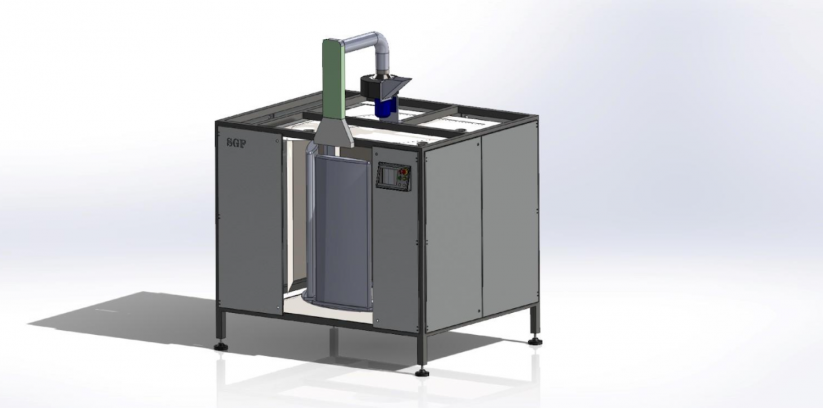

Italian textile machinery specialist Sandonini, in collaboration with SGF, has unveiled the SW6, an innovative boarding machine designed to meet the advanced processing needs of seamless garments, knitwear, circular fabric, and finished textile products.

Responding to industry demand for automation, high quality, and cost efficiency, the SW6 features a range of integrated functions that traditionally required multiple machines and operators. These include garment ironing, fabric sizing, knit stabilisation, fold and crinkle removal, and drying post-washing or dyeing. Suitable for a broad array of fibres including cotton, wool, and blends, the SW6 is presented as a single-solution system with major reductions in manpower, energy consumption, space usage, and production costs.

Its ergonomic oval design ensures operator comfort while enabling rapid throughput. The company notes that only one operator is required to run the machine, significantly improving operational efficiency and reducing labour needs.

Sandonini and SGF have long been active in the development of equipment for boarding and automated packaging processes for seamless garments, including leggings, pantyhose, socks, medical stockings, and knitwear. The SW6 builds on this experience to deliver an all-in-one solution for the finishing and auxiliary stages of garment production.

A video and technical catalogue are available from Sandonini for prospective customers seeking further information.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more