JS Shoes promotes new line of 3D knitted shoes

Karl Mayer has gone one step further with integrated production.

13th March 2019

Knitting Industry

|

Obertshausen

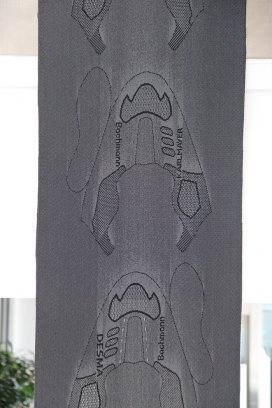

“Uppers manufactured from a single piece are nothing new,” the company explains. “In the sports shoe sector in particular, textile designs, which reproduce the butterfly contours of the entire upper shoe area, are creating quite a stir.”

Karl Mayer has gone one step further with integrated production. The company uses its double-bar raschel technology to also incorporate the insole directly into the textile product. The covering for the lower area of the shoe is produced during the warp knitting process on an RDJ 5/1 and is joined at the sides with the butterfly shape.

A short seam is all that is needed to close the shape of the shoe to which the actual sole is applied directly by injection moulding. This modification to the production process enables making-up costs to be reduced by as much as a third.

“But the potential of the double-bar raschel technology is also manifold in terms of design: Different names can be worked to personalise the shoes, as well as different serial numbers and a wide variety of patterns,” the company adds.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more