Karl Mayer achieves customer proximity despite social distancing

A new course on the Karl Mayer ML 46 will be available as of January 2013 and the first series of courses in India was held in September 2012.

14th December 2012

Knitting Industry

|

Obertshausen

A new course on the Karl Mayer ML 46 will be available as of January 2013 and the first series of courses in India was held in September 2012.

Karl Mayer says it not only supplies state-of-the-art production machines, it also passes on its experience and knowledge to its clients to enable them to carry out their day-to-day operations – true to its promise, ‘We care about your future’.

The Karl Mayer Academy gives students practical information on warp knitting, and the German company says demand for the courses is high. In this year alone, training courses for roughly 200 participants from textile companies all over the world were held at the German headquarters in Obertshausen.

The content and structure of the training courses are constantly being adapted and expanded to suit the requirements of customers. A training course on the ML 46 in Obertshausen and the opening of the Karl Mayer Academy India are designed to increase the transfer of knowledge between the company and its clients. The new Academy opened in September of this year and will offer a programme of courses.

A course on the ML 46 will be available as of January 2013 in the Karl Mayer Academy Germany, with the aim of extending the range of courses available to lace producers. The training machine for this course was assembled in Obertshausen this year. It is 134 inch wide, has a gauge of E 24, and is equipped with all the technical features typical of modern multibar raschel machines. In the main, these include the tried-and-tested string bar concept for producing patterns and the KAMCOS computer platform with Motion Control /Multi Speed functions for controlling the main machine operations.

The ML 46 can reach maximum speeds of 900 rpm. The new ML course is designed to instruct the trainees on how to use this innovative multibar lace machine in a way that is based on what actually happens in practice; they are also given ample opportunity to ask questions. The course lasts two weeks and is held in English, Spanish or German. Please contact Josefin Sindl at [email protected].

In June of this year, Karl Mayer opened its own Academy in India to support the emerging Indian textile industry. The new training centre is located in Surat at the offices of Karl Mayer’s representative for the region, A.T.E. Two courses are currently available:

An Operator Course, which is designed to provide basic information on how to operate the machines

A Warp Knit Basic course, which provides participants with basic information on warp knitting technology and its patterning possibilities.

The first series of courses, comprising the Operator and the Warp Knit Basic Courses, took place from 3 to 5 September and then from 6 to 13 September - with virtually the same number of participants on both courses.

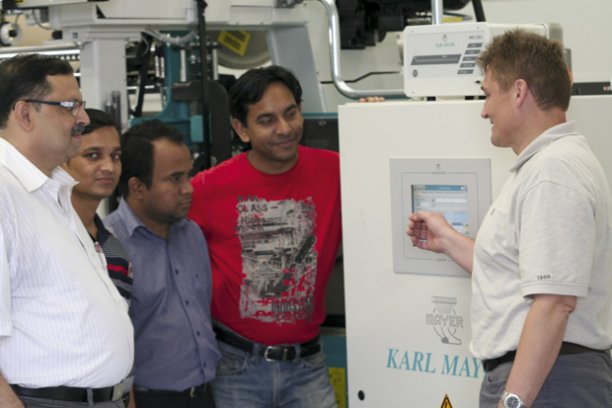

Robert Kuna from the Karl Mayer Academy Germany welcomed five participants from two different local companies. Working in tandem with each other, this guest instructor conducted the first training course at the Karl Mayer Academy India, assisted by Srilesh Trilokekar, who will be in charge of the courses in future.

In the next series of courses, which was held from 20 to 22 September and from 24 September to 1 October, the roles of the two instructors were reversed. This dual training approach was beneficial all round. Whereas the Indian head of training was able to gather some last-minute snippets of information before he went solo, the students were able to profit from the knowledge of both instructors.

They were extremely keen to get to grips with the technology of the training machine, an HKS 3-M; they analysed the various lappings, and developed their own patterns. The hands-on approach is said to have been very well received.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more