Pailung at TITAS 2023

In line with the spirit of this year’s ITMA theme, Pailung featured five different machines, each equipped with its own cutting-edge innovation.

17th July 2019

Knitting Industry

|

Barcelona

Team Pailung at ITMA 2019. © Pailung.

Internationally renowned knitting machinery manufacturer Pailung, showcased its latest innovations at last month’s ITMA, the quadrennial textile and garment technology exhibition, that was be held from June 20-26 in Barcelona.

In line with the spirit of this year’s theme — Innovating the World of Textiles — Pailung featured five different machines, each equipped with its own cutting-edge innovation.

“Pailung believes that every innovation in knitting starts with innovations in machinery. Accordingly, Pailung will be featuring five machines, each equipped with its own distinctive innovation — designed to compel a surge of innovation across the textile ecosystem. These state-of-the-art machines not only improve fabric quality, but also offer features that can accelerate production and reduce cost,” Pailung’s Marketing Representative Mason Chao said in Barcelona.

Pailung booth at ITMA 2019. © Pailung.

“Innovation is central to the Pailung spirit. We’re constantly looking for ways to improve on existing solutions, either by making production faster, more efficient, less labour-intensive or, even better, by completely disrupting the status quo,” emphasised Pailung Chairman, James Wang. “These five innovations are a taste of what Pailung has been tinkering with in our Open Innovation Lab.”

The five innovations on show in Barcelona that Pailung believes will redefine the future of knitting were:

MES – Intelligent manufacturing

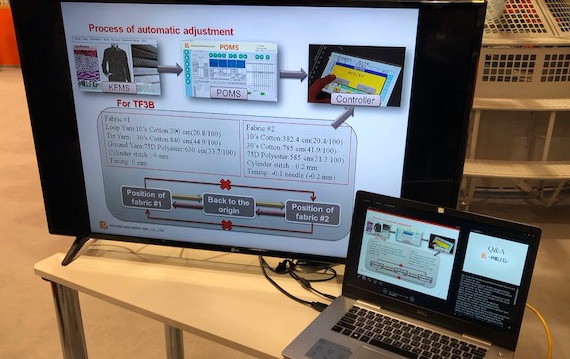

According to Pailung, in addition to monitoring production efficiency using its Pailung Online Monitor System (POMS), being able to exercise complete control is one of the most critical aspects of Industry 4.0.

Pailung’s MES in action at ITMA. © Pailung.

“Rather than manually changing machines’ knitting parameters, MES (Manufacturing Execution System) allows machines to be adjusted through computers, both ensuring consistent knit quality and type, while also streamlining production and achieving strict quality control standards,” the company said.

Pailung technician’s gave live demonstrations at the exhibition, where machines were style changed ‘on the fly’, which was most impressive.

Spinit

Replacing the traditional method of spinning raw materials into yarn, Spinit creates textiles directly from raw materials, significantly shortening the yarn spinning process. This helps save raw material cost, accelerate production, and create high quality fabrics that are soft and light, ideal for polo shirts and other golfing attire.

Spinit uses sliver as its raw material whilst competitors use rovings, fibre-based components which have been further processed than sliver, making Pailung’s system more cost effective at the input stage. © Knitting Industry.

Spinit was available for viewing by invitation only and anyone interested in seeing the ground-breaking technology had to make a reservation. Pailung does not have machines in the market yet but believes it will shortly. Spinit uses sliver as its raw material whilst competitors use rovings, fibre-based components which have been further processed than sliver, making Pailung’s system more cost effective at the input stage.

Knitted 3-Layer High Pile (KDFPS-HW)

As the name suggests, the knitted 3-layer high pile technology simultaneously knits three layers on a single machine, completely avoiding the laborious process of producing the laminated 3-layer high pile and reducing production time by 60%, according to the machine manufacturer. At the same time, KDFPS-HW is said to solve the 2-layer high pile loss issue, both accelerating production and improving fabric quality.

Segue Jacquard (KRTDCJ6)

Equipped with state-of-the-art technology that releases yarn as needed, rather than all at once, KRTDCJ6 can knit up to eight different types of yarn with varying colors, materials, and denier values, without thickening the knit. Segue Jacquard knits vibrant patterns that last longer than printed designs and can create knits with embossed patterns.

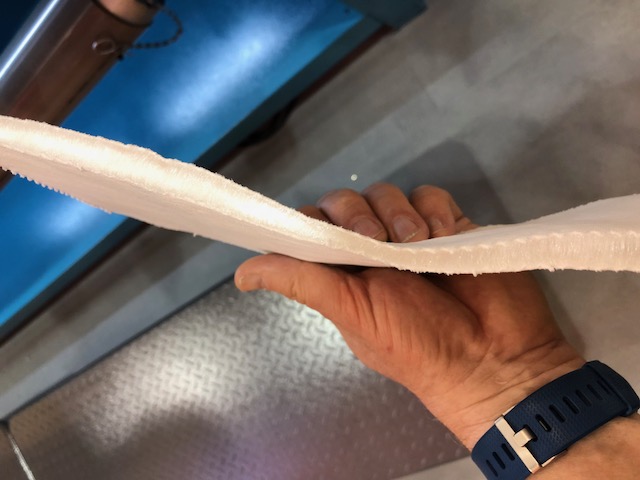

Sculpted Spacer (ISP203)

Spacer has played a revolutionary role in the fabric industry, and sculpted spacer is bringing it to the next level, Pailung says. ISP203 can knit a single piece of spacer fabric with various thicknesses, offering an alternative to padded bras and other apparel.

Pailung’s ISP203 can knit a single piece of spacer fabric with various thicknesses, offering an alternative to padded bras and other apparel. © Knitting Industry.

“The sculpted spacer not only embraces wearers in a snug fit, it also significantly reduces production time by completely eliminating the cutting and patching step that was previously required for shaping,” Mason Chao said.

“These five innovations were be the highlight of Pailung’s booth at this year’s ITMA — and are likely to make tangible changes to the global fabric industry, as these innovations spark new ideas across the world of textiles,” Mr Chao concluded.

Flat knitting innovations

Pailung is known primarily for its circular knitting machinery but it is a also a player in the field of flat knitting, especially in Asia. There were a couple of notable flat knitting innovations on show in Barcelona which are definitely worth a mention.

The first is the model ISP203 single carriage three system flat knitting machine for sculpted spacer fabrics.

The second is the IP093 single carriage three system inverse plating flat knitting machine. Inverse plating is currently on trend and until now has been the domain of the leading flat knitting machine manufacturers.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more