Tropic Knits strikes new path with Brückner line

The R&D 100 Award is a prestigious innovation awards programme, which honours R&D pioneers and revolutionary ideas in science and technology.

6th November 2019

Knitting Industry

|

Hong Kong

The Hong Kong Research Institute of Textiles and Apparel (HKRITA)’s research project – Revolutionary Relaxation Process for Sweater Manufacturing – was recently selected as one of the winners of the R&D 100 Awards in the category of Process/Prototyping. The project involved joint collaboration with The Hong Kong Polytechnic University (PolyU).

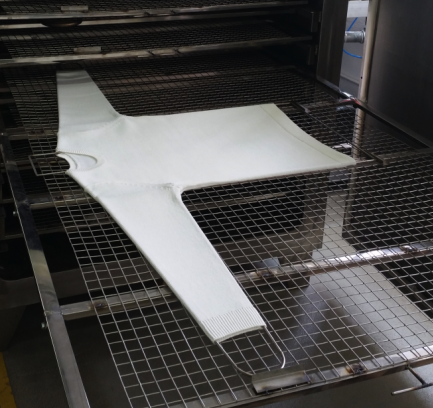

Low pressure relaxation (LPR) process for sweater manufacturing. © HKRITA.

The R&D 100 Award is a prestigious innovation awards programme, which honours R&D pioneers and revolutionary ideas in science and technology. HKRITA’s award winning project involved research into restoring the desired properties and performance of knitted fabrics using a novel relaxation process.

Relaxation of knitted fabrics is a prerequisite to restoration of their properties and performance, and HKRITA has developed a low-pressure relaxation (LPR) process. Unlike the conventional washing and tumble drying (WTD) process, which features mechanical agitation, the LPR process applies micro-agitation to achieve sweater relaxation.

In this way, the LPR process restores more effectively the sweater properties of dimensional stability, fabric appearance and hand feel. The process is based on the principle that when air pressure drops, water evaporates, and its volume expands. The force field created by water vapour expansion in a garment acts on its fibres and yarns. An agitation action occurs, which has a relaxation effect on the garment.

The new process is far more sustainable than the conventional one since it is faster, consumes less energy and discharges no water, the organisation reports.

Mr Edwin Keh, Chief Executive Officer of HKRITA, said: “We are delighted to receive this highly respected award. It is a significant recognition of our endeavours in research and development. The novel low-pressure relaxation process, which successfully addresses the limitations of the traditional relaxation process, is a breakthrough in sweater manufacturing.”

“With the increasing awareness of sustainability across industries and governments around the globe, all textile and apparel industry stakeholders, including HKRITA, strive to develop solutions that minimize the environmental impacts of textile manufacturing. The LPR showcases how our industry can utilize technology to protect the environment while, at the same time, improving manufacturing efficiency”.

Established in 2006, HKRITA is funded by the Innovation and Technology Commission of the HKSAR Government and is hosted by The Hong Kong Polytechnic University. HKRITA contributes to the competitiveness of the textile and apparel industry by providing one-stop services in applied research, technology transfer and commercialization. HKRITA also plays a vital and expanding role in driving sustainable improvements in the industry and thus bringing benefits to society as a whole.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more