Smartex launches 2024 Modern Textile Factory Report

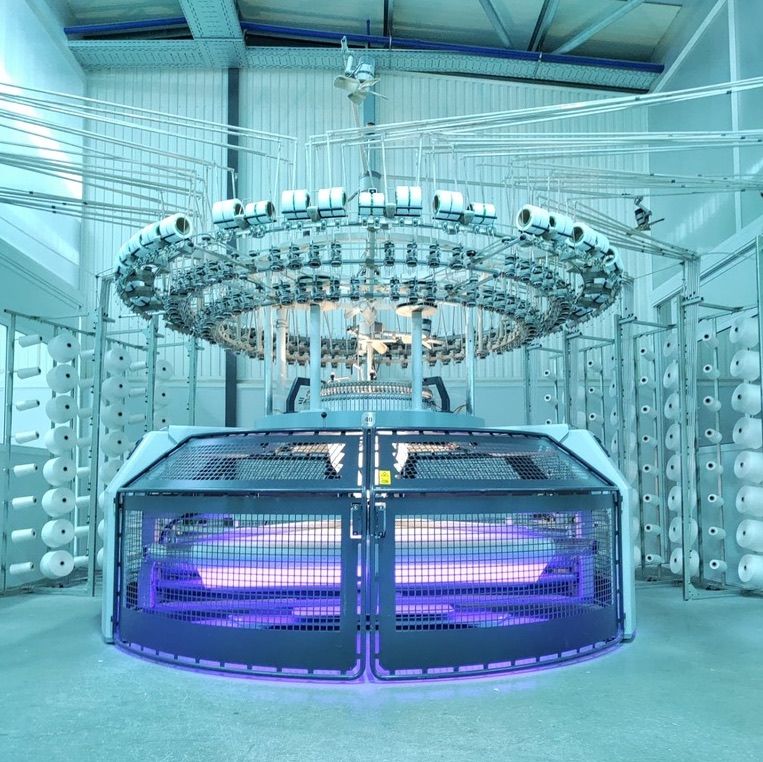

Developer of advanced fabric inspection system for circular knitting machines to grow team, enter new markets and develop new lines.

3rd November 2022

Knitting Industry

|

Porto, Portugal

Lightspeed Venture Partners and Tony Fadell’s Build Collective have led an oversubscribed $24.7M Series A funding round of Portugal headquartered deep-tech start-up Smartex, to ensure the sustainability and profitability of textile factories worldwide.

Smartex is a developer of hardware-enabled, machine-vision driven software to detect textile defects in real-time in textile manufacturing, including circular knitting. The automated identification process reduces textile waste, CO2 emissions, energy, water, production time and capital expenditure by automatically shutting down production on fault detection, in order to prevent waste of materials.

With our technology and talent, we will be able to pioneer a new chapter in the fashion industry and ultimately to reduce waste and costs

Other notable investors in this $24.7M Series A round include H&M Group, DCVC, SOSV’s HAX, Spider Capital, Momenta Ventures, Bombyx Growth Fund, Faber, EX Capital and Fashion for Good with which Smartex initiated multiple projects with its partners such as the Kering Group (Gucci, Balenciaga, etc), PVH (Tommy Hilfiger, Calvin Klein, etc), Pangaia and others. This follows their $2.9M Seed round in 2019 co-led by DCVC and Spider Capital.

The Series A funds will allow Smartex to expand its business strategically to new geographies, continue to grow the team as well as develop product lines to help manufacturers and fashion brands improve control of their production while increasing textile quality and traceability.

Defects in the textile industry tend to be compounded, meaning that when fabric travels down the supply chain with defects that were not detected it often leads to entire textile rolls being discarded or burned, causing enormous environmental and financial impact in one of the world’s largest industries.

The textile and fashion industry is the 3rd most polluting industry in the world, Smartex says, producing a monstrous amount of textile waste each year with no signs of slowing down. It is estimated that 150 billion garments are produced annually in this $3T industry which accounts for 20% of global water waste and 10% of global carbon emissions, the company says.

The textile industry operates on thin margins, Smartex stresses, and has a considerably high defect rate. The industry is currently dependent on human vision and manual inspection to detect textile defects. Smartex empowers textile manufacturers to take control of their production line through real-time textile defect detection, data-driven analysis and alerts.

“Our customers are just as engaged as we are with the products we are building,” says Co-founder, CTO, and winner of Web Summit’s 2021 PITCH Competition Antonio Rocha. “In order to create solutions to best serve them, we are always listening and open to their feedback. Together we are working on a new era of high quality, waste-free manufacturing which will lead to improved transparency and traceability across the textile supply chain from yarn to retail.”

Customers include leading innovators in knitted fabric production such as Tintex Textiles, Familitex, Toraman Tekstil, Ekoten, among many others. During a video case study, Mario Jorge Silva, Founder of Tintex Textiles & HATA, says that: “Smartex - with its artificial intelligence and tracking processes - is an economically viable solution because it not only saves time but anticipates and helps in the elimination of problems that may arise later on.”

As the global sustainability movement continues to gain traction, consumers and regulators are increasingly pushing the fashion and textile industry to adopt cleaner, more responsible production. The European Commission has recognized Smartex as fundamental for Industry 4.0 Projects in textile factories.

Gilberto Loureiro, Co-founder and CEO of Smartex, comments: “We are privileged to be in a very unique position to add intrinsic value to a giant industry that is fundamental and touches so many lives, fueling our mission to sustainability and profitability of textile factories worldwide. With our technology and talent, we will be able to pioneer a new chapter in the fashion industry and ultimately to reduce waste and costs. All efforts are necessary to generate a positive impact as we strive to solve this global challenge and contribute to a more sustainable world.”

Smartex is currently present in several markets across Europe, Central Asia, South America, and Africa, and has plans to expand further into Asia in 2023. With steep growth in revenues, clients, and headcount, the company continues to hire worldwide talent to join the mission of empowering factories all around the world to produce with less waste.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more