Glenmuir celebrates 30 years of Ryder Cup success

Opinion

Tencel capacity has been expanded hugely with the coming on stream of the state of the art giant production plant for Lyocell fabrics.

1st October 2014

Janet Prescott

|

Paris

Lenzing announced good news at Premiere Vision. The fibre innovation group has experienced some adverse price fluctuations in the course of the year, but at the same time Tencel capacity has been expanded hugely with the coming on stream of the state of the art giant production plant for Lyocell fabrics. It was built with due regard to environmental issues at Lenzing in Austria.

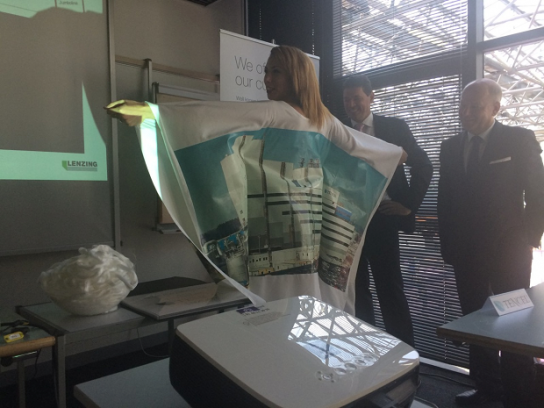

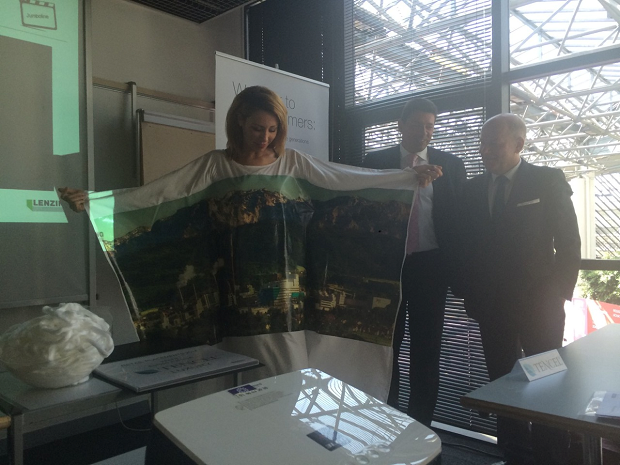

The atmosphere at Lenzing was upbeat, symbolised by the model walking among the conference, wearing a printed Tencel shirt with the huge image of the new plant displayed across her body front and back, much to the pride and amusement of the Lenzing presenters, who included CCO Robert van de Kerkhof and Dieter Eichinger VP Global Business Development. The installation is the largest production facility for Lyocell fibres in the world, new industry writ large.

Going into operation after only 24 months in the construction, and an investment of €150 million, the huge plant is reportedly running at full capacity. The new factory is the first of its type with a single production line, and has an annual capacity of 67,000 tons.

Tencel has been presented recently as an eco fibre for wovens, like denim and shirting. The accent is now on knitwear developments, benefiting from new finishing processes and special fibre spun for knitwear applications. Lenzing cite ‘tremendous potential’ in this area ‘Tencel can provide added value when it comes to the quality ... it will set a new standard in this sector’ said Robert van de Kerkhof. The main advantage is seen as the continuing brightness of colour achieved, its sheen and the fact that it is washable and crease-free.

100 per cent Tencel knitwear is being targeted strongly at the fashion sector, especially with the current emphasis on jersey, and for flat knitwear. Blends with other fibres, natural and synthetics fibres are also seen as important areas for knits. Tencel A100 is for use with synthetic blends and wool, Tencel LF in cotton blends. Taking up the trend for finer knitted fabrics for men and women, Tencel knit types are also available in a micro version.

“The new facility is opening new doors for us” Lenzing US Marketing lead Tricia Carey explained to Knitting industry News, “Already Levi’s are running Tencel 28/62 cotton, and the fact that it is being used for bedding and sheeting is leading the customers towards the product

“As to how Tencel is accepted, the US heritage is about cotton, but cotton prices have gone up and Tencel blends are ecologically sound, so we have expanded our supply chain. Knitwear developments are in the pipeline, with printed Tencel and blends of Tencel /cotton. Digital printing is already in the stores. There is a whole activewear market, using Tencel/poly inside and out, the use of commercial details, like reflective tape, and importantly, seamless garments. Anything with too much needle is not good for the US”, she added. “The Caribbean and Central America are synthetics driven, so blends are the way to go, jog pants, knit trims, sports activewear, whether real or fashion sportswear, the aesthetic is right.

“The benefits we can point out are colour retention, sheen and hydrophilic qualities. Tencel is easy to knit, and the ideal blending partner is cotton. It bridges the natural and synthetic worlds.’

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more