Terrot closes Italian subsidiary

New system redefines stability and flexibility in large-diameter circular knitting.

22nd January 2026

Knitting Industry

|

Chemnitz, Saxony, Germany

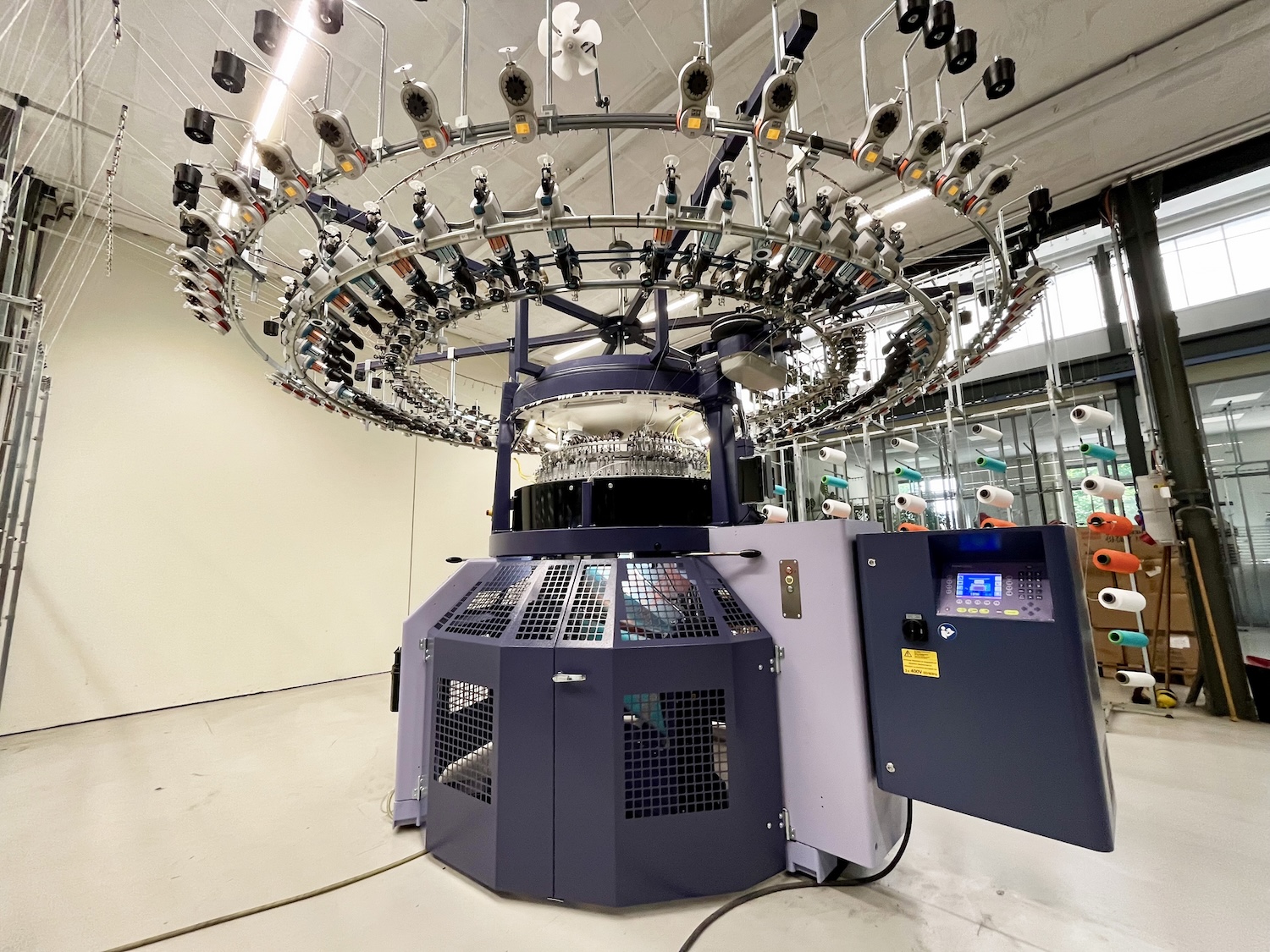

Terrot Textilmaschinen GmbH has introduced its new T-Frame platform, a universal machine frame developed to meet rising demands for flexibility, stability and operational safety in large-diameter circular knitting. Unveiled in Chemnitz on 21 January 2026, the new platform is designed as a future-ready foundation for both current and next-generation industrial knitting machines.

Circular knitting manufacturers worldwide are under increasing pressure to respond quickly to changing market requirements while maintaining consistent fabric quality amid tighter cost, labour and sustainability constraints. At the same time, expectations around ergonomics, machine safety and long-term investment security continue to grow. The new T-Frame has been engineered to address these challenges by combining mechanical robustness with a modular, adaptable design.

At the heart of the development is a newly engineered tubular machine frame manufactured from premium steel. Drawing on almost three decades of experience in large-diameter machine design, Terrot has completely rethought the frame architecture to handle higher mechanical loads while improving precision and accessibility. The intelligently welded construction provides high structural rigidity while supporting modular adaptability across different machine configurations.

A single standardised frame platform supports multiple extraction and take-down variants, reducing mechanical complexity and enabling faster configuration changes. Integrated cable routing, centralised display positioning and optimised component layouts replace traditional add-on solutions, improving both operator ergonomics and machine safety.

In production environments, the T-Frame delivers tangible operational benefits. One universal frame supports multiple machine configurations, allowing rapid adaptation to changing fabric requirements. Enhanced structural stability ensures knitting precision at industrial speeds, particularly in large diameters from 26 to 54 inches. Standardised components and improved accessibility reduce set-up times and simplify maintenance, while intelligent cable management minimises failure points and supports long-term process reliability. The platform has also been designed to accommodate future machine generations, helping to protect customer investment.

“With the T-Frame, we have focused on the foundation of machine performance,” said Michael Lau, Head of R&D at Terrot. “By rethinking the frame architecture, we deliver higher stability, easier handling and a level of flexibility that meets today’s production needs while enabling future technological developments.”

The Terrot T-Frame platform is available for large-diameter tubular circular knitting machines in multiple frame sizes and configurations. The company will present the new platform at upcoming international trade shows, where visitors will be able to see the technology in operation.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more