Karl Mayer presents daring outfit for cold days

An interview with Thomas Fischer, head of application technology at Terrot GmbH.

28th May 2025

Knitting Industry

|

Shanghai

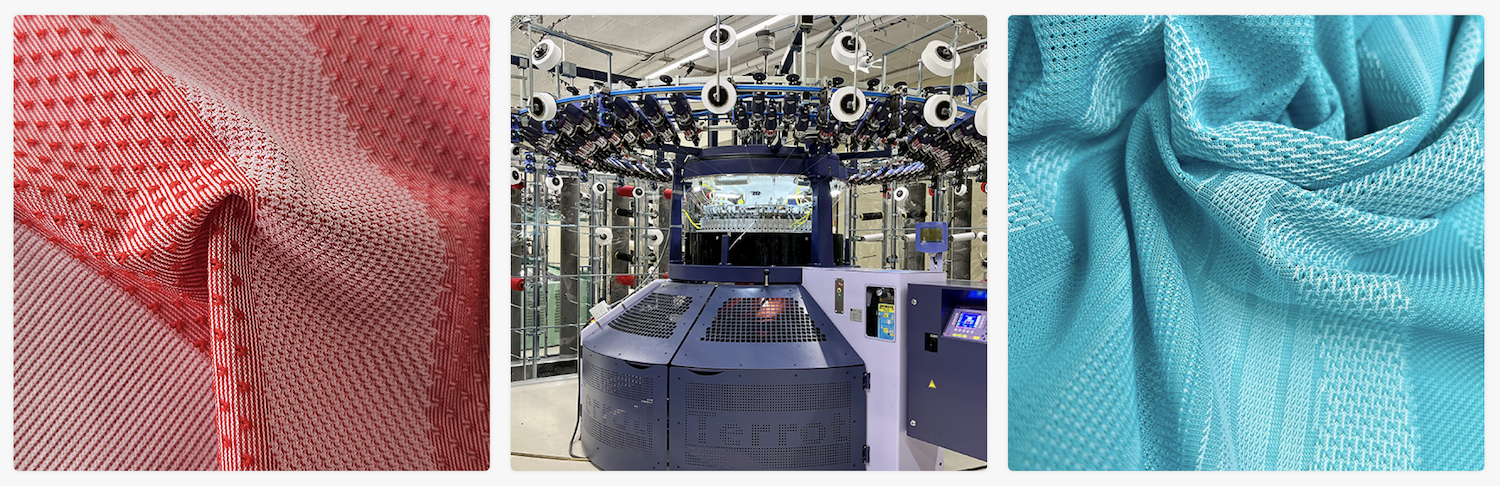

In this interview the Material Alliance speaks to Thomas Fischer, head of application technology at Terrot GmbH, one of the leading circular knitting machine manufacturers in the market. Over the last eighteen years, Thomas has seen it all - trends come by, textiles transform and the market changes, but one thing continues to be key at Terrot and that is quality.

In this interview with Thomas, we discover industry best practice at first hand.

Material Alliance (MA): What are some of the most exciting trends or innovations in stitch design today?

Thomas Fischer (TF): The first thing is for all flexibility and sustainability, meaning sustainability for the planet and because of climate change. At Terrot, we are building fine-gauge machines in the mechanical sector and also in the jacquard sector, especially the transfer machine now in gauge E28/E28.

It is the finest machine which can do jacquard fabric in single jersey, double jersey and also whole structure.

So, a fine gauge means you have thinner yarns, a lighter weight of a garment at the end, convenient for warm days and also for sports. It is very necessary to have these lightweight fabrics and also closed sides of a fabric where you cannot see through.

Also, the use of natural yarns like cotton, bamboo, mixed yarns and some others for moisture transport and especially, for our machines, creating garments for the high price sector, in designing at first but also in functionality.

MA: What are the most common challenges you face when creating complex stitches and how do you overcome them?

TF: Challenges while knitting are not so big because in the past, we had the same knitting elements like today. It means we have needles, we have sinkers, or pattern checks or pattern elements, we also have feeding systems.

The only way to create complex stitches is by modifying elements: to get more feeders on the machine, faster speed, more production output and finer gauge machines. To develop new garments, and new stitches, the stitch combination is important, the combination for mechanical machines and which cams I need, which stitch repeat, create bigger stitches or smaller stitches are also relevant.

MA: What are the challenges in knitting innovation that will transform the field of knitting?

TF: Yeah, this happens every time, the customer wants the best quality fabrics, with high technology and the cheapest price point to produce fabrics or garments. For example, a plain fabric, I have to make the dyeing process, fixing, I have to cut the fabrics, sew the fabrics, etc.

People are in need for this work, which is why the textile sector has shifted to low-wage countries over time. But especially if I look now to seamless technology, this is a production for higher specialized garments, in a high price section, because it needs different yarns, dyed yarns, so I will get a very specialized fabric or product at the end.

Sometimes we get very interesting samples. So, we decide, if we have a very special sample from the past, we look into our library, okay, we say this is a setting of a machine with needles and cam settings we had from the past, but in a coarse gauge machine. Let's do it in our new machine, in a high feeder machine and in a fine gauge machine. Let's see if the structure is working and what will be the result. The structure will be the same, but the fabric will look completely different

MA: What advice would you give to someone who starts exploring advanced knitting

TF: We have a lot of history in knitting. It means in the past also knitting was very popular, the machines were a little bit different. We had not so fine gauges, but also the people developed a lot of different structures.

For example, if I see in the normal knitting market without the jacquards, they already make a lot of different samples. And especially we also get some pieces of fabric, and the customer is asking to analyse it and provide the yarn path, the stitch repeat, maybe the cam setting, that means the setting of a machine. If you can find out which yarn counts and which yarn, it would be helpful.

We have a big library of different structures, a big library for arrangement of needles and cams. And sometimes we get very interesting samples. So, we decide if we have a very special sample from the past. If we look into our library, we say this is a setting of a machine with needles and cam settings we had from the past, but in a coarse gauge machine. Let's do it in our new machine, in a high feeder machine and in a fine gauge machine. Let's see if the structure is working and what will be the result. The structure will be the same, but the fabric will look completely different with very light weight and so on, maybe with new yarns, with new colored yarns and you have very good effects. The best advice is to copy from our history.

MA: What are the main factors affecting softness in knitted materials?

TF: At first, of course, if you look at softness, it's very clear. You get a very soft fabric if you use high engineered yarns. It means it's a big difference between a standard yarn with a low filament in synthetic or you have a high filament yarn, you can feel it. Also, without any plating of elastane, a high filament yarn is very soft. It's laying good on the skin and so on.

Any yarn can be high or low filament. For example, if you have a normal polyester yarn, this is a cheap yarn, but you feel the difference between a low fibre yarn and, for example, standard 30 fibres and the difference between 90 fibres. Especially between polyester and polyamide. Polyamide, for example, is more flat, has a little bit of cooling effect and it gets a better form after washing. Another example is cotton; you have different stable lengths. It means the fibre of the cotton has different lengths. For example, in Egypt, cotton is better than in Uzbekistan.

Then you have the production of the yarn. For example, cotton. At the start it has a lot of dirt inside. In the spinning mill, the cotton is processed into high-quality yarn, especially when the cotton is combed and short fibres are removed. So, I’ll have a very smooth and stable yarn, which also knits fast.

If you have a long staple yarn, after a lot of washing the garment is the same. You will have no holes and no shrinking. This is much better also in the feeling.

MA: What are the main factors affecting elasticity?

TF: I have some, especially for seamless, you are using normal yarns, you can blend yarns with elastane, or you have covered yarns, core yarns. And if I have a high tension of the elastane, the spandex, I have more shrinking in the fabric. So, I have to look, did I need more pressure in the garment or not? If I have a low percentage of elastane, it's normal, like a little stretch. But if I have a high tension, for example, just for underwear, for shapewear, I use a big percentage of elastane and a big elasticity. It depends, how is my machine setting in case of yarn tension between the normal yarn and the plated yarn or the core yarn. Higher tension, it gets more tight fabrics. The other one was breathability.

MA: What are the main factors affecting breathability?

TF: Breathability, of course, if I have a plain fabric, I have a lot of surface laying on the arm, on the back and so on. If I have a structure, let's say, like channels in the fabric. Or, if I make some patterns, I will have some channels, this way I know I will only have 50% of the textile laying on the body, creating a little bit of breathability, allowing the air to go inside. This Is great for special climates and in sports and so on.

Or you have a whole structure for breathability and to bring moisture out and so on. You can knit a structure for that; we call it technical textile with real functionality. For example, knit a fabric one side is polyester, another side is fibre yarn, like modal or cotton. And this moves out the moisture better. With wool, it is the same. A combination with some jacquards can have a good function for breathability.

MA: How to continue learning in seamless and circular technology?

TF: Every day, when knitting, you learn new things. If you like it, you are in the right place. If you come in the morning to work and say, okay, now it's seven. I do my work, and I go home, it's possible to learn, but it's the same every day.

But, if you come in the morning and say: we have this project, we will discuss, let's make it happen, and nobody knows everything. You must connect your team and say: this is our target, let's look at it, let's start and we will see what happens. You don't know if it works or not, but you need to start, let's move, let's look. We have to modify the machine setting/yarn setting a little bit, change the tension, the design. At the end, everything will be okay, and if not, you start again.

If you go in the evening and say, tomorrow we make these changes, like changing the yarn, the yarn is like a human. It's not a thing. It's a living part: sometimes it's good, and sometimes the yarn is angry.

So you learn new things every time together with the project, also with the companies you work with, you get a lot of knowledge.

Want to know more about Thomas Fischer and the work at Terrot? Get in touch here.

Original article written by Estrella Martinez and republished with the kind permission of Material Alliance.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more