Santoni takes part in Textile Evolution

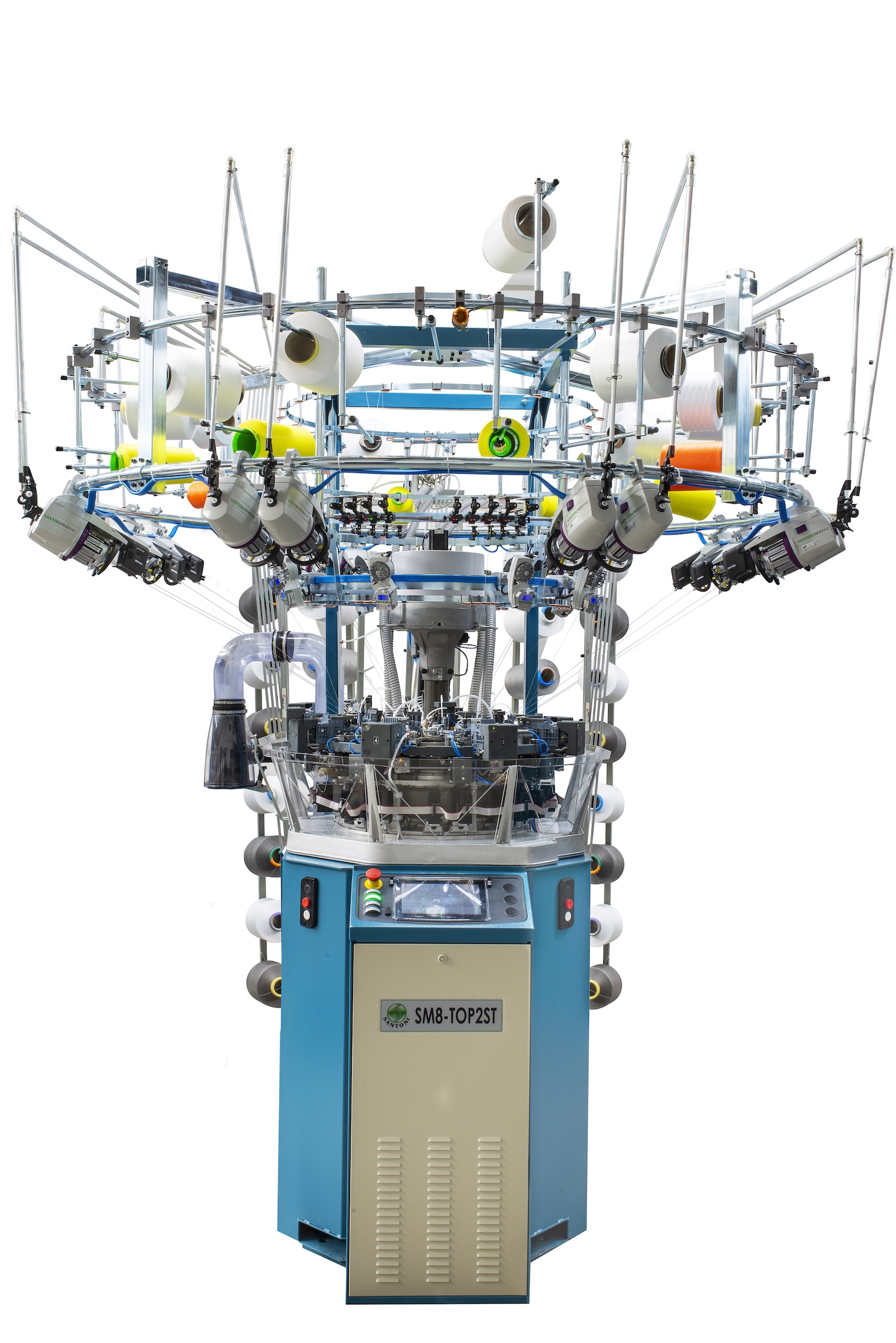

Italian circular knitting technology further evolves with the introduction of the new SM8-TOP2ST machine with needle-by-needle selective terry.

21st May 2024

Knitting Industry

|

Brescia, Italy

Santoni says it is evolving its renowned seamless knitting technology with the new SM8-TOP2ST machine, which can produce innovative 3D structures with needle-by-needle selective terry, through a mechatronic device protected by two patents and developed by Santoni R&D.

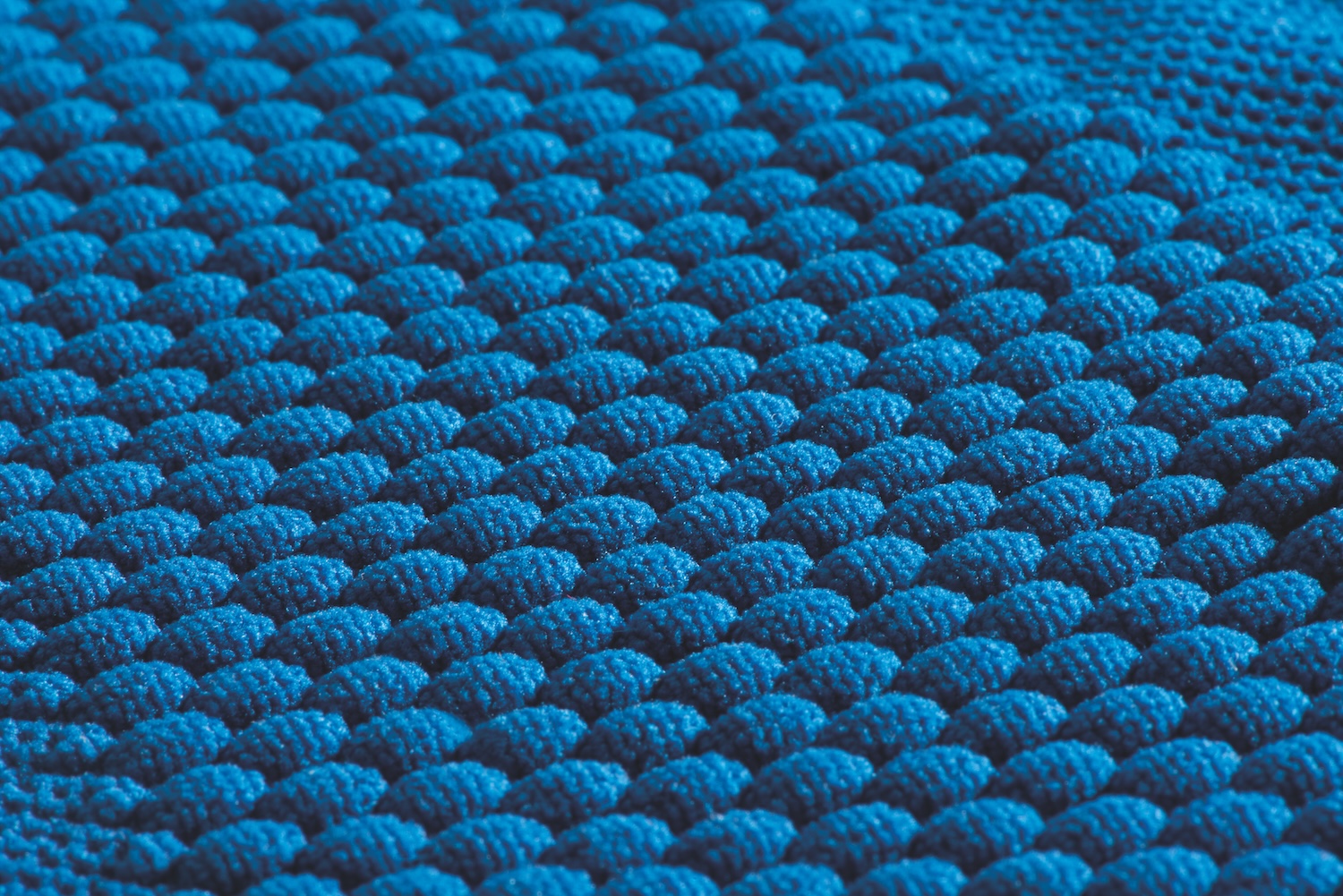

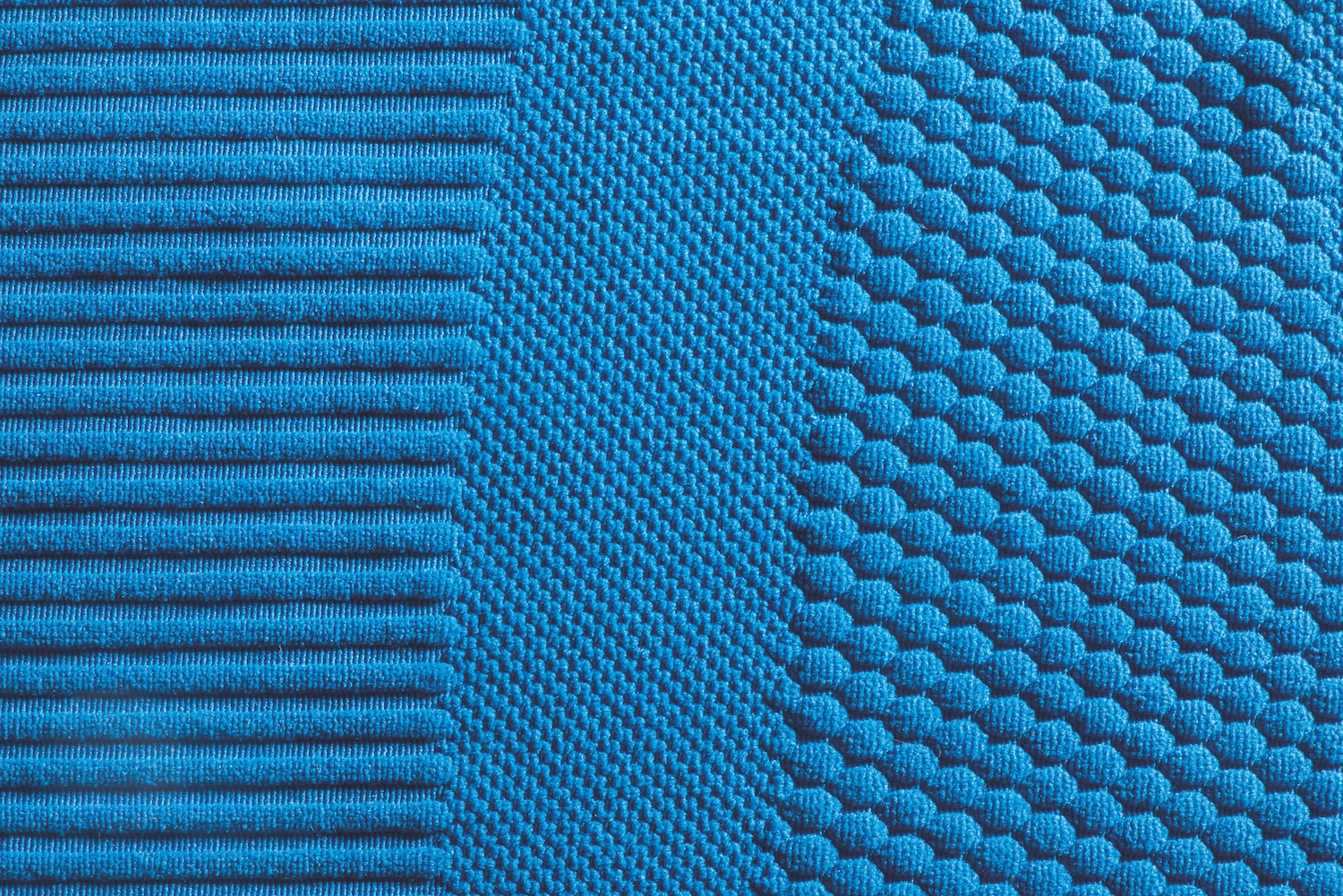

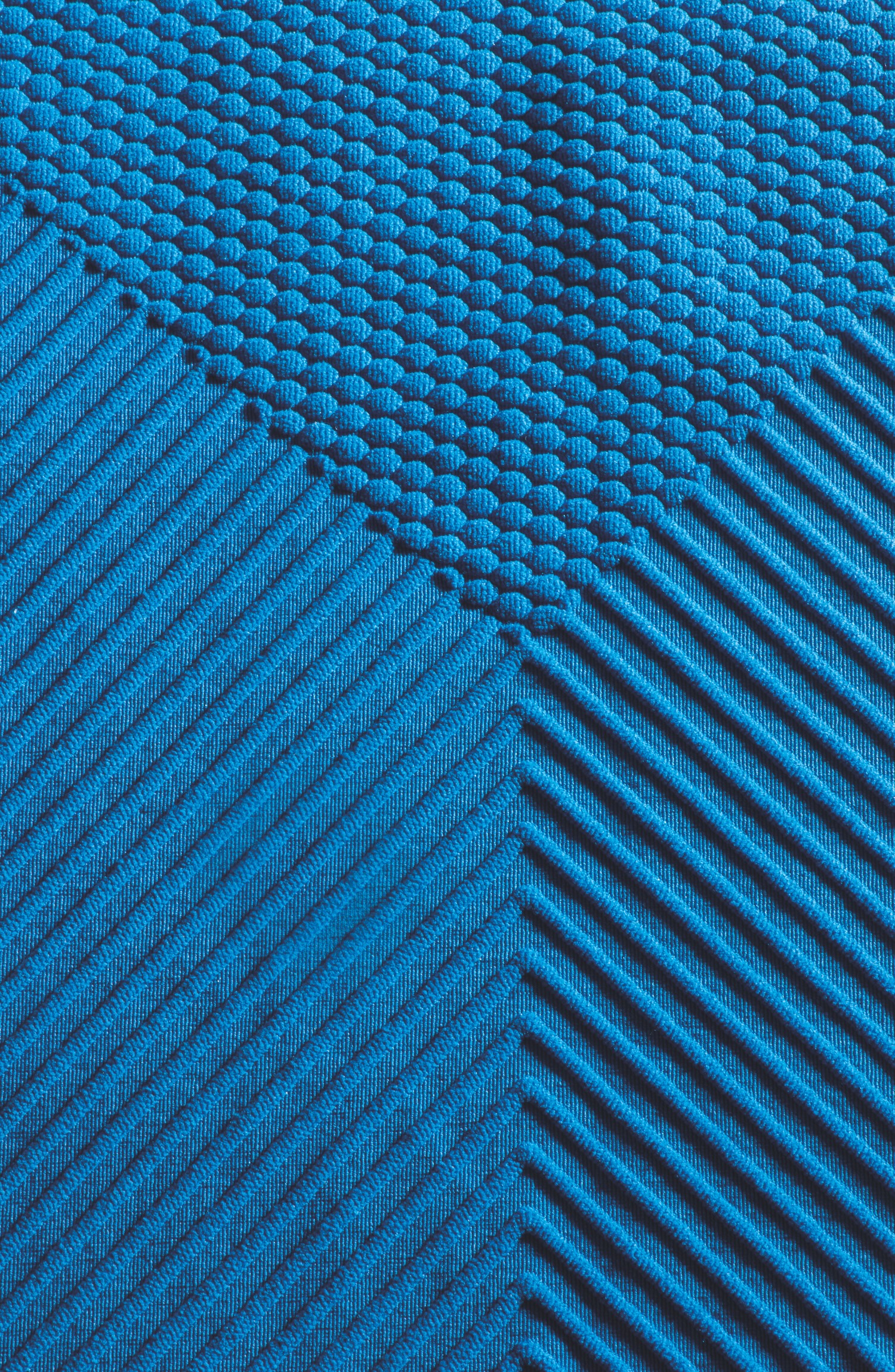

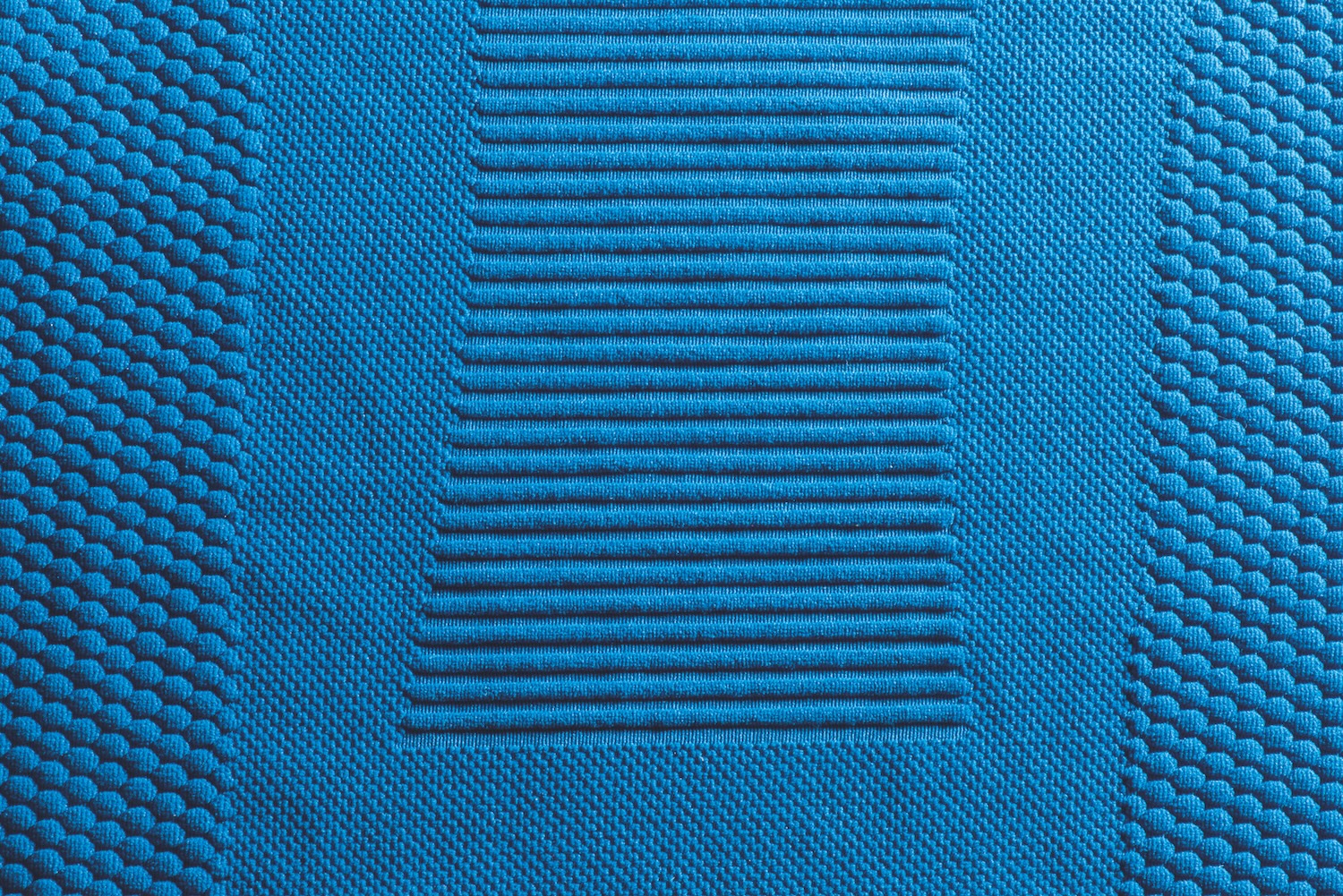

The fabrics and garments, shown above and below in gauge 28, have achieved a new level of functionality and comfort, the company says. On the one hand, the 3D structures with selective terry allow the creation of strategically placed channels for optimal breathability and thermoregulation. On the other, they can also build 3D geometric areas that provide a massaging effect and ultimate softness.

“The seamless technology used up to now has allowed the production of 3D structures achieved wrinkling the fabric through needles in miss position,” says Santoni Marketing Manager Patrick Silva. “Today, with SM8-TOP2ST our customers can finally produce garments with the same well-known benefits of seamless knitting but drastically reducing production times.”

“To protect the several textile patterns, and particularly the 3D structures with selective terry, which this revolutionary machine can produce, Santoni has registered four patents.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more