Karl Mayer acquires YTC yarn tensioner technology

The machinery manufacturer Karl Mayer has developed a selection of new warp knitted fabrics and models in time for the company’s open-house event, aimed to give new impetus to the clothing and sportswear sectors. These new textile innovations include a completely new type of plissé fabric, a lace decorated with sports motifs, and a super-lightweight laminate for use in functional outdoor jackets.

18th February 2014

Knitting Industry

|

Obertshausen

The machinery manufacturer Karl Mayer has developed a selection of new warp knitted fabrics and models in time for the company’s open-house event, aimed to give new impetus to the clothing and sportswear sectors.

These new textile innovations include a completely new type of plissé fabric, a lace decorated with sports motifs, and a super-lightweight laminate for use in functional outdoor jackets.

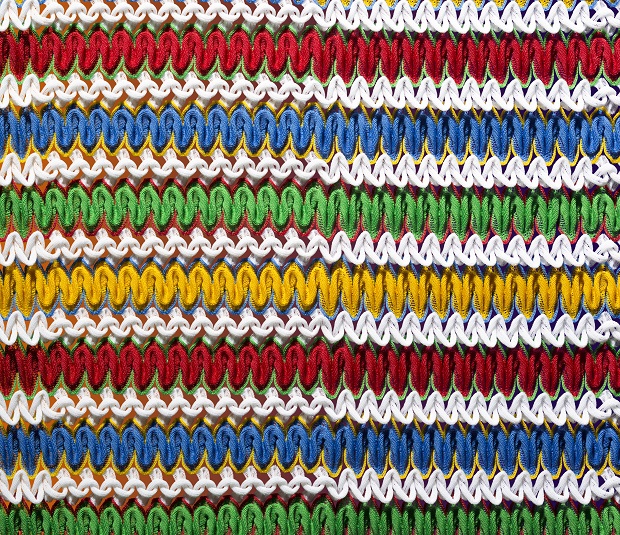

This fabric has a design similar to a pressed pattern on the reverse side and has a clearly defined plissé construction on the right side. The clearly defined folded construction is arranged in differently coloured, narrow strips.

The pronounced three-dimensional look of the fabric matches the current trend for the renaissance of the traditional, handcrafted look, which makes it look as if it had been made by hand, yet the bold, multi-coloured pattern in the pop art style also gives it a modern twist.

This plissé fabric was produced on an HKS 4-M EL in a gauge of E 28. The appearance of the fabric is produced by combining a conventional technique with a new method of forming folds. The plissé effect is produced conventionally by the threading-in arrangement typical of the pattern and the relevant lapping.

The relationship between the needle threading arrangement and the movement of the bars produces long yarn bands with shorter plissé yarns arranged behind them. Over a specific number of revolutions of the main shaft, the fine yarns do not form stitches but tie-in the bands later.

Unlike a typical plissé pattern, the yarn bands are only fixed at the bases in a second segmented sequence. Each of the heads of the loops engage with the adjacent row. This creates a looser construction and produces a new braid-like effect that is quite new to warp knitting.

Karl Mayer has developed a lace with a sporty look. The pattern of it features modern sports symbols in sweeping lines. The motifs are separated by chequered flags used to mark the end of races. The motto of the Olympic Games, ‘Faster, Higher, Stronger’, is written in Latin at the sides.

A dainty scalloped pattern is used at the edges of this new style of lace as an homage to classic lingerie lace. This sporty design was produced on an MJ 42/1 B in a gauge of E 24. The blend contains 15% elastane to provide optimum comfort stretch during wear.

Lightness and function are the latest buzzwords in the clothing sector, the company reports. Two new developments illustrate the contribution that warp knitting is making to the theme of wind and weather proof outdoor jackets made from two layer laminates.

A warp knitted textile was used as the carrier substrate and combined with a film membrane to produce this composite. With their relatively open, lightweight constructions, these specifically engineered knitted fabrics are said to provide excellent slip resistance. The elongation of the warp knitted fabrics can also be set optimally.

Compared to weft-knitted fabrics worked in the appropriate lapping and materials, the elasticity is low enough to prevent the film from tearing, yet high enough for the garment to feel comfortable when worn.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more