Substantial growth forecast for India’s textile and clothing industry

Karl Mayer and Grabher support wearables projects with competence platform.

12th March 2024

Knitting Industry

|

Obertshausen, Germany

In recent years, Karl Mayer has made a name for itself as a specialist in the field of wearables. The Textile-Circuit division of its Textile Makerspace has already produced a wide range of electrically conductive warp-knitted items for a wide variety of applications, including a sensor shirt, a gesture control system and a conductive charging station.

In order to drive the topic forward, the innovative textile machine manufacturer has signed a cooperation agreement with the Grabher Group and delivered an MJ 52/1-S to the specialist for high-tech textiles in Lustenau. Managing Director Günter Grabher officially inaugurated the key machine for project work in the smart textiles sector in May 2023.

The versatile machine is involved in various research projects but is also available for new projects and tasks. The smart textiles competence team at Karl Mayer and Grabher is looking forward to supporting the ideas and work of interested parties also outside the research network with its know-how and the possibilities of the MJ 52/1-S.

Smart textile alliance ready for new challenges

The possibilities of Grabher and Karl Mayer in promoting smart textiles projects are considerable. Both partners have their own expertise and capacities in this area: Karl Mayer with Textile-Circuit of its Textile Makerspace, Grabher with V-trion, a subsidiary that develops customised concepts for customers as a research institute. Grabher also uses a wide variety of textile machines and processes for its production and can therefore contribute its comprehensive technological expertise and network to project work.

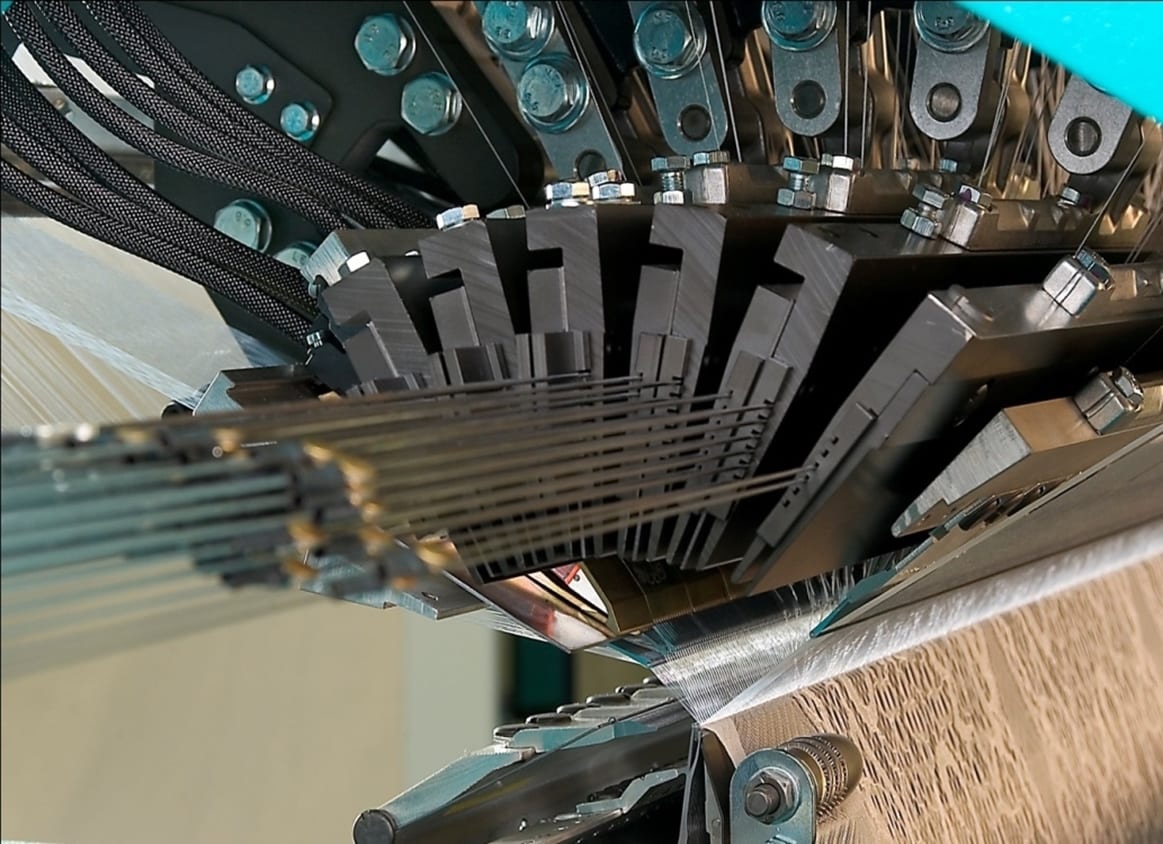

The MJ 52/1 S is also an extremely flexible project machine. The 138-inch model in gauge E 28 produces a wide range of warp-knitted fabrics and incorporates conductive material directly into the textile surface - exactly where it is needed and with the structure that is required. The basis for the tailor-made fibre placement is Karl Mayer's string bar technology. The proven system for controlling the pattern guide bars ensures a fast, established textile production process and a high degree of pattern freedom.

"The potential of the MJ 52/1 S in the production of electrically conductive textiles is truly amazing. I'm always surprised at what we can do with it and what doors we can open for new applications," says Franziska Guth, Product Developer for Textile Technology at Karl Mayer.

If you would like to know more about the possibilities and are looking for inspiration or support in the field of smart textiles, the passionate product developer for textile technology is the right person to contact at [email protected].

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more