Trendsetting Karl Mayer machines at ITMA

In the field of raschel machines, a new RSJ 4/1 EL will be premiered at ITMA.

13th May 2019

Knitting Industry

|

Obertshausen

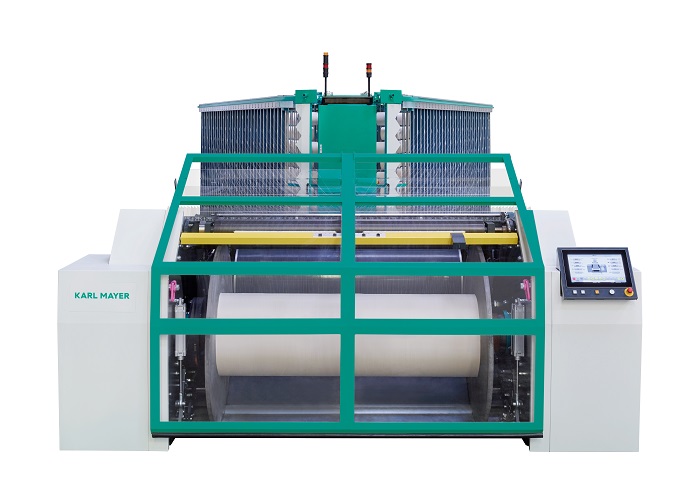

OJ 91/1 B machine. © Karl Mayer

Karl Mayer will present the latest technical solutions for an efficient, flexible production in the fields of warp knitting, warp preparation and technical textiles, as well as new digital products of the sector’s software trendsetter KM.ON at next month’s ITMA 2019, in Barcelona. Under the motto Future of Textiles, the company will also present clever textile solutions for new, exciting applications and markets, as well as contributions to the topic of sustainability.

In the field of raschel machines, a new RSJ 4/1 EL will be premiered at ITMA. Offering 50% more working width at the same speed compared to its predecessor, this machine is highly productive and flexible. Thanks to the EL technology, it is possible to ensure a rapid pattern change and to produce patterns with long repeats. For the development of new articles, the innovative model takes full advantage of the integration into the KM.ON eco system.

Under the Lace.Express trademark, Karl Mayer launched the OJ series in 2016, tailored to the special needs of the apparel market. At ITMA 2019, the manufacturer will present a self-contained, complete 134" machine platform for the intimate sector. The company will offer a B- (Back) version and a F-Jacquard (Front) version for each of the representatives. The special highlight of the system: the related models are compatible to one another. In Barcelona, an OJ 91/1 B will be on show.

In its Future of Textiles application area, Karl Mayer will be presenting solutions, such as comfortable bras with few seams, a sporty body made from novel power lace with shaping and supporting effects, as well as a swimsuit in lace look. As far as the double raschel technology is concerned, Karl Mayer will present the new RDPJ 6/2 EL 138ʺ, in a gauge of E 24. The warp-knits are marketed under 4D-Knit.Solutions and will also be on display in the Future of Textiles area.

New RDPJ 6/2 EL machine. © Karl Mayer

Karl Mayer will also be displaying the first three-bar HKS model with electronic guide bar control. The new HKS 3-M-ON offers the same performance in terms of speed and design variety as the previous version, but thanks to an innovative gear solution it is faster and simpler during pattern change.

Karl Mayer will showcase its new Multi-Matic 32 for producing sample and short production warps. This new machine offers all the advantages of the Kamcos 2 platform. Thanks to the integrated OPC UA interface in particular, the machine can be digitally networked and the operating data can be collected in real time.

Regarding the direct beamers, Karl Mayer has consistently pursued its twin product line strategy. The new Isodirect was successfully launched at ITMA Asia 2018 as a standard model, and the Prodirect will be presented to the public as a version for the premium market at the next ITMA in Barcelona. Moreover, Karl Mayer will be showing the new stop motion Multiguard as prototype.

Guests will be able to experience the latest generation of sectional warping machines via a live link at Karl Mayer’s German site in Hausen. The Prowarp will be demonstrating its new features and capabilities. The latest innovations include a modern module for the camera-assisted recording of production data, which is important for the high reproducibility of beam build-up. The Proactive Warping is also new.

The company will be showing innovative technical solutions for guaranteeing improved efficiency and sustainability in the denim production in its Future of Textiles sector. One main focus is Sustainable Denim. Karl Mayer presents a newly developed technology for an indigo dyeing process in nitrogen atmosphere, which ensures an optimum setting of the dye in terms of solidity and brilliant tone, at the same time requiring less dye bath volume, chemicals and water.

The Prodirect will be presented to the public as a version for the premium market. © Karl Mayer

Also on show will be the new Link-Matic system for the automatic knotting of the batches on the Prodye-S indigo machine and the Prosize sizing machine.

At ITMA Asia 2018, Karl Mayer launched its own digital brand, KM.ON, the associated digital product portfolio with eight categories, and the first solutions. Other offers will follow just in time for the next ITMA in Barcelona.

k.production is also launching its first product. This new digital tool combines a PDA system with a ticket system to enable any disruptions in production to be managed efficiently. k.management enables the current production process to be viewed remotely and now includes a greater range of parameters. The new features in the k.maintenance system focus on the topic of planned maintenance. Finally, the k.innovation covers the first software developments, which will enable customers to shorten their time-to-market considerably by adapting their workflows and processes. The key for accessing all the KM.ON solutions, k.ey, has also been upgraded.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more